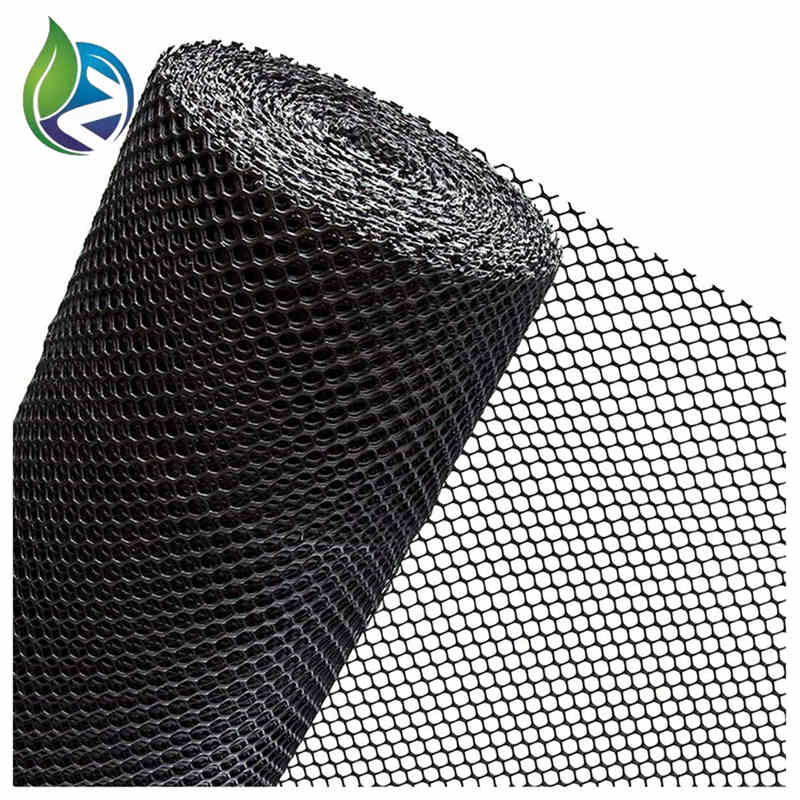

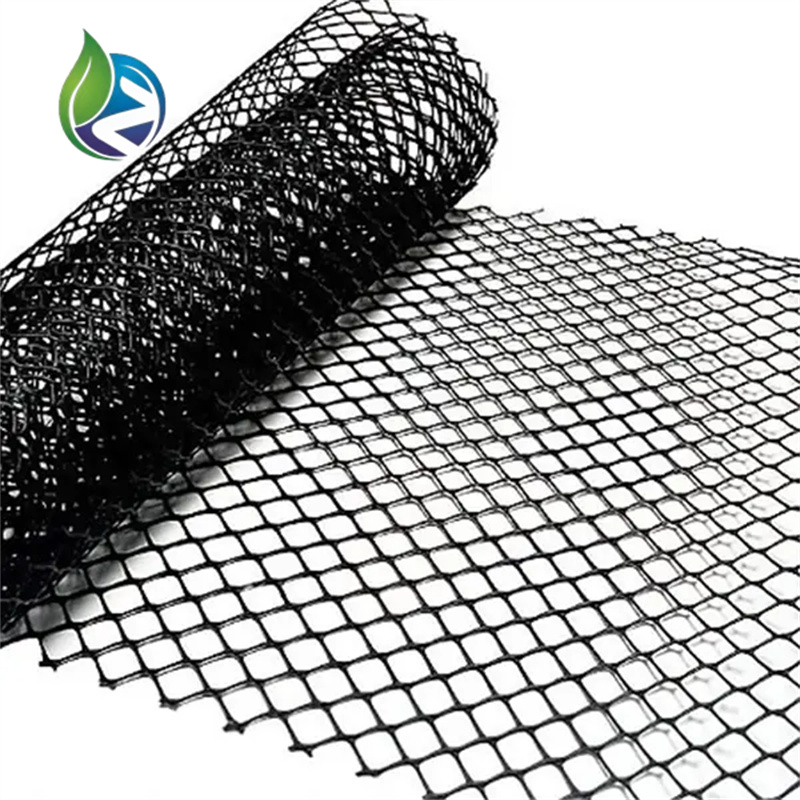

Plastic Mesh HDPE Geonet

Manufacturing Process

Industrial manufacturing workflow of Plastic Mesh HDPE Geonet:

Resin drying and automated material feeding system

Melt extrusion through multi-channel flat die

Precision strand forming under controlled temperature

Cross-laminated strand bonding at node intersections

Online thickness and density monitoring

Cooling via calibrated water bath system

Surface texturing and edge trimming

Roll winding and protective film wrapping

Product Definition

Plastic Mesh HDPE Geonet is a three-dimensional drainage and filtration geosynthetic manufactured from high-density polyethylene. It is designed to provide continuous in-plane flow for liquids and gases while maintaining structural stability under soil loads in civil and environmental engineering systems.

Technical Parameters and Specifications

Standard technical data for Plastic Mesh HDPE Geonet used in engineering drainage and protection projects:

Raw material: High-Density Polyethylene (HDPE)

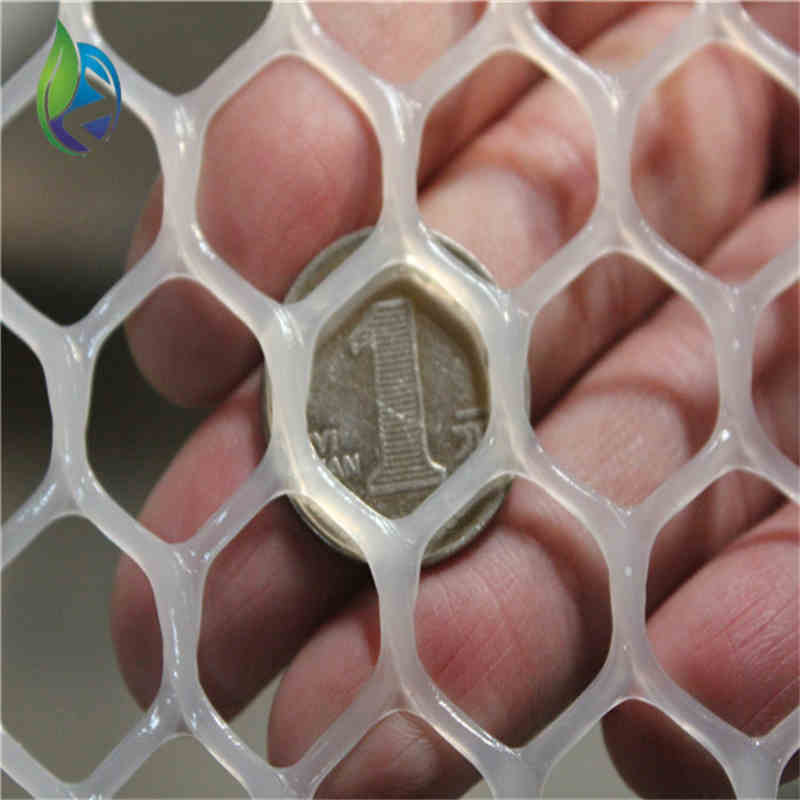

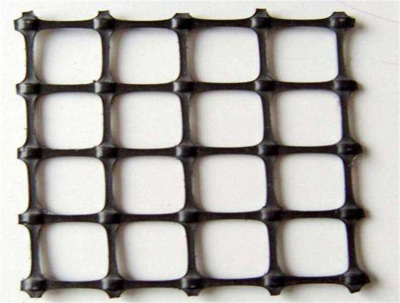

Structure: Bi-planar or tri-planar extruded mesh

Thickness range: 4.0 – 8.0 mm

Mass per unit area: 300 – 700 g/m²

Compressive strength at 10% strain: 200 – 600 kPa

In-plane transmissivity (1.0 gradient): 1.0×10⁻³ – 5.0×10⁻³ m²/s

Tensile strength: 5 – 15 kN/m

Carbon black content: 2.0 – 2.5%

Standard roll width: 2 m – 4 m

Roll length: 30 m – 100 m

Structure and Material Composition

Engineering structure of Plastic Mesh HDPE Geonet:

Extruded HDPE core strands forming continuous flow channels

Upper and lower intersecting ribs for load transfer

Node junction points with fusion-bonded integrity

Material composition:

Virgin HDPE resin

Carbon black UV stabilizer package

Thermal antioxidants

Optional composite layers:

Bonded nonwoven geotextile for filtration control

Adhesive-laminated protective sheets

Manufacturing Process

Industrial manufacturing workflow of Plastic Mesh HDPE Geonet:

Resin drying and automated material feeding system

Melt extrusion through multi-channel flat die

Precision strand forming under controlled temperature

Cross-laminated strand bonding at node intersections

Online thickness and density monitoring

Cooling via calibrated water bath system

Surface texturing and edge trimming

Roll winding and protective film wrapping

Industry Comparison

| Drainage Material | Flow Capacity | Structural Stability | Clogging Resistance | Typical Use |

|---|---|---|---|---|

| Plastic Mesh HDPE Geonet | High | High | Excellent | Landfill and foundation drainage |

| Gravel Drain Layer | Moderate | Variable | Moderate | Traditional subsoil drainage |

| Geocomposite Drain | High | High | High | Vertical wall drainage |

| Foam Drain Board | Low | Low | Low | Light-duty drainage |

Application Scenarios

Engineering applications of Plastic Mesh HDPE Geonet for professional stakeholders:

Landfill leachate collection layers for EPC contractors

Tunnel and underground structure drainage for civil engineers

Green roof water management for developers

Retaining wall and basement drainage systems

Heap leach mining pad drainage layers

Core Pain Points and Engineering Solutions

Drain clogging in fine soils: Integrated channel structure maintains stable flow paths.

Excessive hydrostatic pressure: High in-plane transmissivity relieves water buildup.

Low compression resistance: Tri-planar mesh structure provides improved load-bearing stability.

Long construction cycles: Lightweight rolls enable rapid installation and reduced manpower.

Risk Warnings and Mitigation Measures

Risk of geonet crushing under high loads – conduct compressive creep testing during design.

Risk of UV degradation before burial – limit exposure time to less than 14 days.

Risk of improper overlaps – maintain minimum 150–300 mm overlap.

Risk of contamination by fines – specify composite geotextile when filtration is required.

Procurement and Selection Guide

Define required drainage flow rate and gradient conditions.

Calculate compressive loads from cover soils and structures.

Select thickness based on long-term creep performance.

Verify carbon black and antioxidant package through test reports.

Check compatibility with geomembrane and geotextile systems.

Confirm project compliance with ASTM and ISO geosynthetic standards.

Request factory production traceability and lot identification.

Engineering Case Example

A coastal landfill project incorporated Plastic Mesh HDPE Geonet as the primary leachate drainage layer over a 60,000 m² cell. The system was installed beneath a geomembrane liner and nonwoven geotextile. Monitoring showed stable flow capacity and no collapse under sustained waste loading over the initial operational period.

FAQ

Q1: What is the main function of Plastic Mesh HDPE Geonet?

A: In-plane drainage and gas venting.

Q2: Can it be installed on slopes?

A: Yes, with suitable anchoring design.

Q3: Does it replace gravel drainage layers?

A: In many engineered systems, yes.

Q4: What is the typical design life?

A: More than 50 years in buried conditions.

Q5: Is it resistant to chemical leachates?

A: Yes, HDPE is chemically resistant to most acids and bases.

Q6: How is flow capacity tested?

A: By in-plane transmissivity laboratory testing.

Q7: Can the geonet be cut onsite?

A: Yes, with standard cutting tools.

Q8: Is special installation equipment required?

A: No, standard site equipment is sufficient.

Q9: Can it be supplied as a composite?

A: Yes, with bonded geotextiles.

Q10: Which standards govern geonet use?

A: ASTM, ISO, and local geotechnical standards.

Call to Action (CTA)

For project-specific pricing, technical datasheets, or engineered samples of Plastic Mesh HDPE Geonet, submit a formal inquiry with soil parameters, loading conditions, and applicable standards to receive technical support and documentation.

E-E-A-T Author Credentials

This content is prepared by a civil and geotechnical engineering specialist with more than 15 years of experience in geosynthetic drainage systems, landfill engineering, and infrastructure project consulting for EPC contractors and developers.

You have not enough Humanizer words left. Upgrade your Surfer plan.

Technical Specifications

| Property | Specification |

|---|---|

| Material | High-Density Polyethylene (HDPE) |

| Mesh Size | 10mm × 10mm / 20mm × 20mm |

| Thickness | 1mm–3mm |

| UV Stability | UV-stabilized for extended outdoor use |

| Tensile Strength | ≥ 20 MPa |

| Roll Width | 1m–5m |

| Roll Length | 50m–100m |

| Color | Green / Black / Custom |