Filament Geotextile

Composite geomembrane is divided into a cloth a film and two cloth a film, a wide width of 4-6m, according to different specifications of different weights, generally 200-1500g/square meter, tensile, tear resistance, top break and other physical and mechanical performance indicators are high, the product has high strength, good extension performance, deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, good impermeability and other characteristics.It can meet the needs of civil engineering such as water conservancy, municipal, construction, transportation, subway, tunnel, engineering construction, seepage prevention, isolation, reinforcement, crack prevention and reinforcement.It is often used for anti-seepage treatment of DAMS, drainage ditches, and anti-pollution treatment of waste yards.

In modern dam construction, the demand for advanced waterproofing and soil protection materials is higher than ever. One of the most effective and reliable solutions in this field is the composite geomembrane with filament geotextile for dam infrastructure. This innovative material combines the impermeability of geomembranes with the strength and durability of filament geotextiles, providing a robust barrier against seepage, erosion, and structural failure.

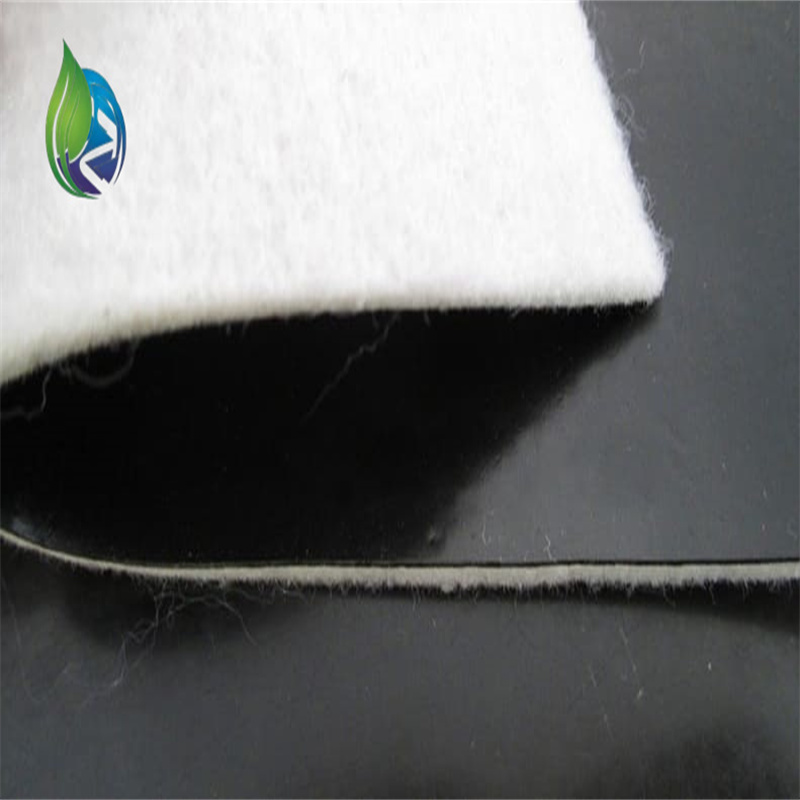

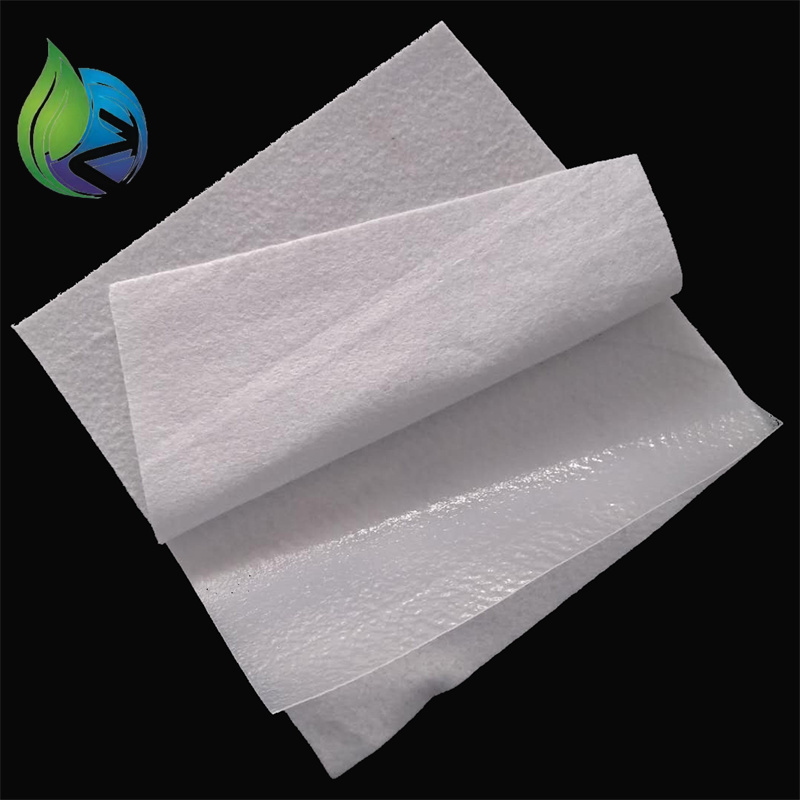

What is a Composite Geomembrane with Filament Geotextile?

A composite geomembrane with filament geotextile for dam use is a multilayered geosynthetic material, typically composed of high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) geomembrane laminated with one or both sides of polyester filament nonwoven geotextile. This design enhances the product's overall performance in terms of:

Seepage control

Mechanical strength

Chemical resistance

UV stability

Puncture protection

This makes it an ideal material for large-scale water retention projects such as dams, reservoirs, and canals.

Key Benefits of Composite Geomembrane with Filament Geotextile for Dam Projects

Using composite geomembrane with filament geotextile for dam construction offers several technical and economic benefits:

Superior Seepage Resistance

The geomembrane core ensures excellent impermeability, effectively preventing water loss and groundwater contamination.Enhanced Tensile Strength

The filament geotextile layer increases the tensile strength, allowing the material to withstand deformation and subsidence.Improved Puncture and Tear Resistance

This composite structure resists mechanical damage during installation and from natural movements such as soil settlement.Long Service Life

Resistant to ultraviolet radiation, aging, and chemical corrosion, it ensures longevity even in harsh environments.Simple Installation

Lightweight and flexible, it can be installed quickly, reducing labor costs and project timelines.

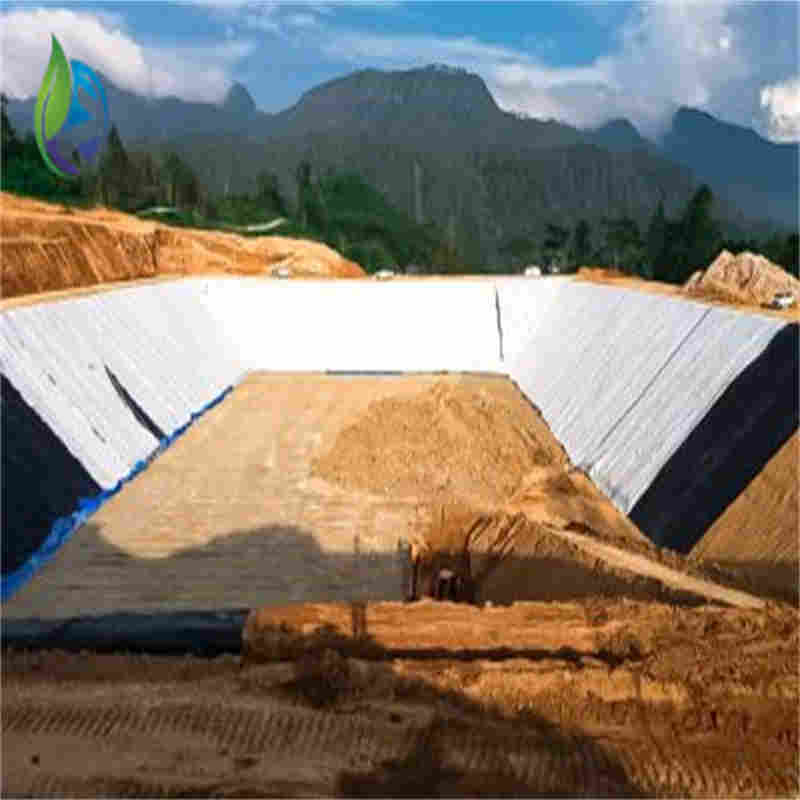

Applications of Composite Geomembrane with Filament Geotextile for Dam

The composite geomembrane with filament geotextile for dam use is not limited to the core structure. It finds applications in:

Dam foundations and upstream slope protection

Secondary containment layers in reservoirs

Seepage-proofing of embankment dams

Drainage and separation systems

Protective linings in spillways and canals

Its adaptability to various geotechnical and hydraulic conditions makes it suitable for both new constructions and dam rehabilitation projects.

Why Engineers Choose Composite Geomembrane with Filament Geotextile for Dam Structures

Choosing the composite geomembrane with filament geotextile for dam engineering ensures that the dam structure remains stable, leak-free, and durable. Engineers value this material for its high performance under dynamic load, thermal expansion, and hydrostatic pressure, especially in extreme climate regions.

Technical Specifications

Typical properties of a high-quality composite geomembrane with filament geotextile for dam construction include:

Thickness: 1.0 mm to 2.5 mm (geomembrane layer)

Weight: 200–600 g/m² (geotextile layer)

Tensile Strength: > 15 kN/m

Peel Strength: > 7 N/mm

Puncture Resistance: > 500 N

These parameters can be customized according to project needs.

Quality Control and Compliance

Reliable manufacturers ensure that composite geomembrane with filament geotextile for dam products comply with international standards such as:

ASTM D5885 / D6392 / D1004

ISO 10319 / 13433

GB/T 17643-2011 (China)

EN 13249–13256 (EU)

Certified materials undergo rigorous testing to ensure mechanical, hydraulic, and chemical performance.

Sustainable and Cost-Effective Dam Engineering

Incorporating composite geomembrane with filament geotextile for dam applications contributes to environmental sustainability by reducing water loss, preventing soil contamination, and extending the dam's operational lifespan. Its long-term cost-efficiency makes it a smart investment for government and private sector infrastructure projects.

Choosing the Right Supplier

To fully leverage the benefits of composite geomembrane with filament geotextile for dam construction, it's essential to choose a supplier with technical expertise, product certification, and reliable after-sales support. Look for manufacturers offering:

Customized production

Technical guidance

On-site installation assistance

Strict quality control

Conclusion

The composite geomembrane with filament geotextile for dam use represents a modern, high-performance solution that combines impermeability, durability, and strength. For engineers and contractors aiming to build long-lasting, secure, and eco-friendly dams, this material is the clear choice. With proper selection and installation, it plays a pivotal role in the success of any hydraulic engineering project.

Two cloth with one membrane: