Hdpe Geomembrane Pond Liner

Manufacturing Process

HDPE geomembrane pond liner is produced through controlled industrial extrusion processes:

Selection and inspection of virgin or qualified resin

Precise blending of carbon black and additives

High-temperature melting and homogenization

Flat-die or blown film extrusion

Thickness calibration and surface texturing (if required)

Cooling and stress relaxation

Online quality monitoring (thickness, defects)

Roll cutting, labeling, and protective packaging

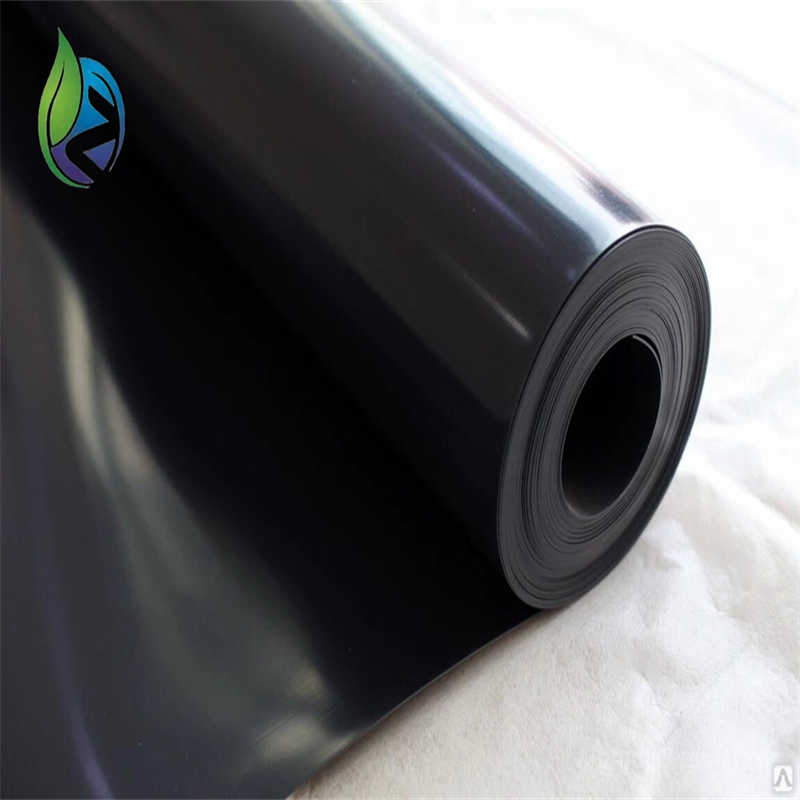

Product Definition

HDPE geomembrane pond liner is a high-density polyethylene impermeable lining material engineered for water containment, seepage control, and environmental protection in ponds, reservoirs, and aquaculture systems, offering long-term chemical resistance, durability, and structural stability.

Technical Parameters and Specifications

Typical technical specifications of HDPE geomembrane pond liner used in engineering projects include:

Raw material: High-Density Polyethylene (HDPE)

Thickness range: 0.5 mm – 3.0 mm

Density: ≥ 0.94 g/cm³

Tensile strength at yield: ≥ 15 MPa

Elongation at break: ≥ 700%

Tear resistance: ≥ 200 N

Puncture resistance: ≥ 500 N

Carbon black content: 2.0 – 3.0%

Carbon black dispersion: Grade 1 or 2

Service temperature: -40°C to +60°C

Design service life: ≥ 30–50 years (buried conditions)

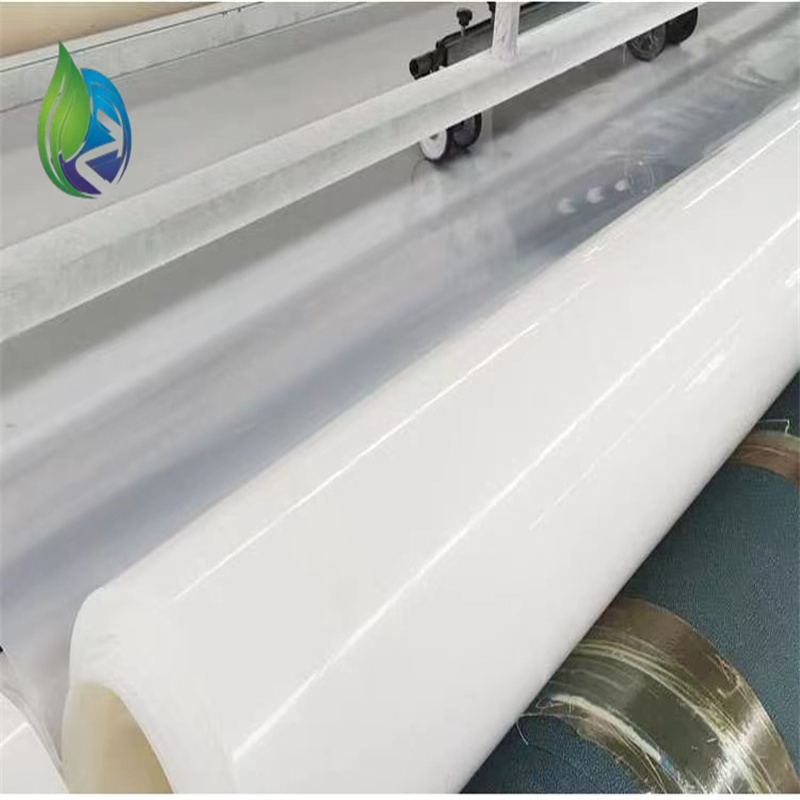

Structure and Material Composition

The performance of HDPE geomembrane pond liner is defined by its material formulation and uniform structure:

HDPE Resin Matrix: Provides impermeability and mechanical strength

Carbon Black: Enhances UV resistance and weather durability

Antioxidants: Prevent thermal and oxidative degradation

Smooth or Textured Surface: Optional textures for slope stability

Homogeneous Sheet Structure: Ensures consistent thickness and performance

Manufacturing Process

HDPE geomembrane pond liner is produced through controlled industrial extrusion processes:

Selection and inspection of virgin or qualified resin

Precise blending of carbon black and additives

High-temperature melting and homogenization

Flat-die or blown film extrusion

Thickness calibration and surface texturing (if required)

Cooling and stress relaxation

Online quality monitoring (thickness, defects)

Roll cutting, labeling, and protective packaging

Industry Comparison

| Liner Type | Impermeability | Chemical Resistance | Flexibility | Service Life |

|---|---|---|---|---|

| HDPE Geomembrane Pond Liner | Excellent | Excellent | Medium | 30–50 Years |

| LDPE Geomembrane | Excellent | Good | High | 20–30 Years |

| EPDM Rubber Liner | Excellent | Good | Very High | 25–40 Years |

| Clay Lining | Medium | Poor | Low | Variable |

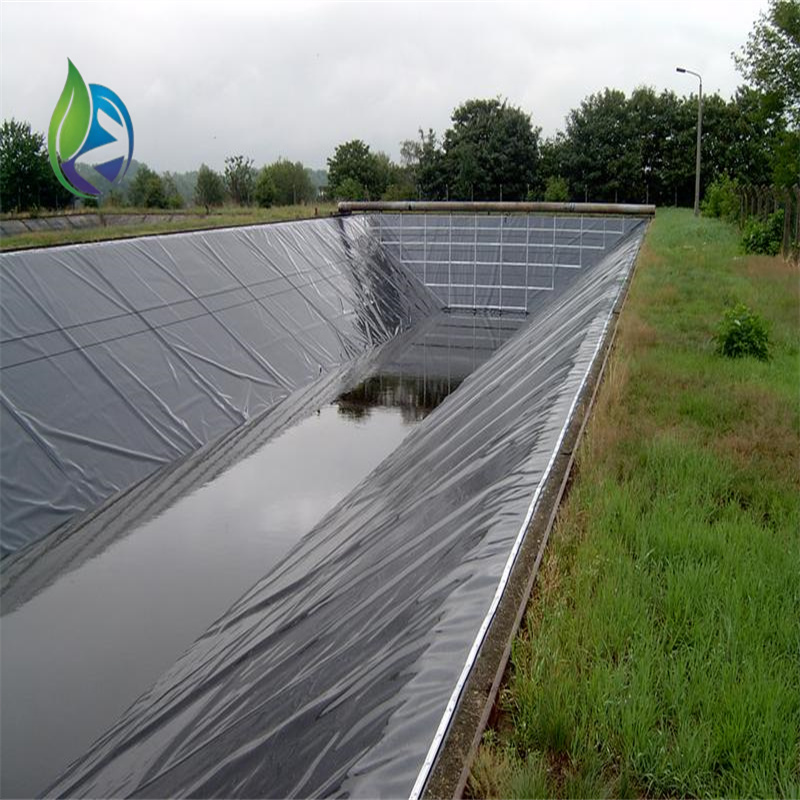

Application Scenarios

HDPE geomembrane pond liner is widely adopted by EPC contractors, developers, and operators for:

Aquaculture ponds and fish farms

Irrigation reservoirs and water storage ponds

Wastewater and effluent treatment lagoons

Industrial process water containment

Landscape and decorative ponds

Mining and tailings ponds

Core Pain Points and Solutions

Pain Point: Water leakage and seepage losses

Solution: Continuous impermeable HDPE geomembrane pond linerPain Point: Chemical attack from water or soil

Solution: Excellent chemical resistance of HDPE materialPain Point: UV degradation in exposed conditions

Solution: Carbon black stabilized formulationPain Point: Installation damage and puncture

Solution: High puncture and tear resistance with protective layers

Risk Warnings and Mitigation

Potential risks and recommended mitigation measures include:

Subgrade damage: ensure smooth, compacted base with geotextile cushion

Improper welding: use certified hot wedge or extrusion welding

Thermal expansion: allow slack during installation

UV exposure during storage: store rolls covered before installation

Procurement and Selection Guide

Define pond size, depth, and design life

Select appropriate liner thickness

Confirm chemical compatibility with contained water

Check compliance with relevant standards

Review third-party test reports

Evaluate welding and installation support

Assess supplier production capacity and delivery time

Engineering Case Study

In a commercial aquaculture project, a 1.5 mm HDPE geomembrane pond liner was installed over a compacted soil base with nonwoven geotextile protection. After four years of continuous operation, inspections confirmed zero leakage and stable water quality, meeting design and environmental requirements.

FAQ

What thickness is suitable for fish ponds? Commonly 0.75–1.5 mm.

Is it safe for aquaculture? Yes, inert and non-toxic.

Can it be exposed to sunlight? Yes, with carbon black protection.

How are seams joined? By thermal welding.

Does it resist algae and bacteria? Yes, smooth surface limits adhesion.

Can it be repaired? Yes, by patch welding.

Is it suitable for cold climates? Yes, down to -40°C.

What is the roll width? Typically 5–8 meters.

Is a geotextile required? Recommended for protection.

Does it meet environmental regulations? Yes, widely approved.

Call to Action

To request pricing, technical datasheets, installation guidance, or project samples of HDPE geomembrane pond liner, please provide your project details for professional evaluation.

E-E-A-T Author Statement

This article is authored by geosynthetics engineers and environmental materials specialists with over 20 years of experience in pond lining systems, water containment engineering, and international infrastructure projects.