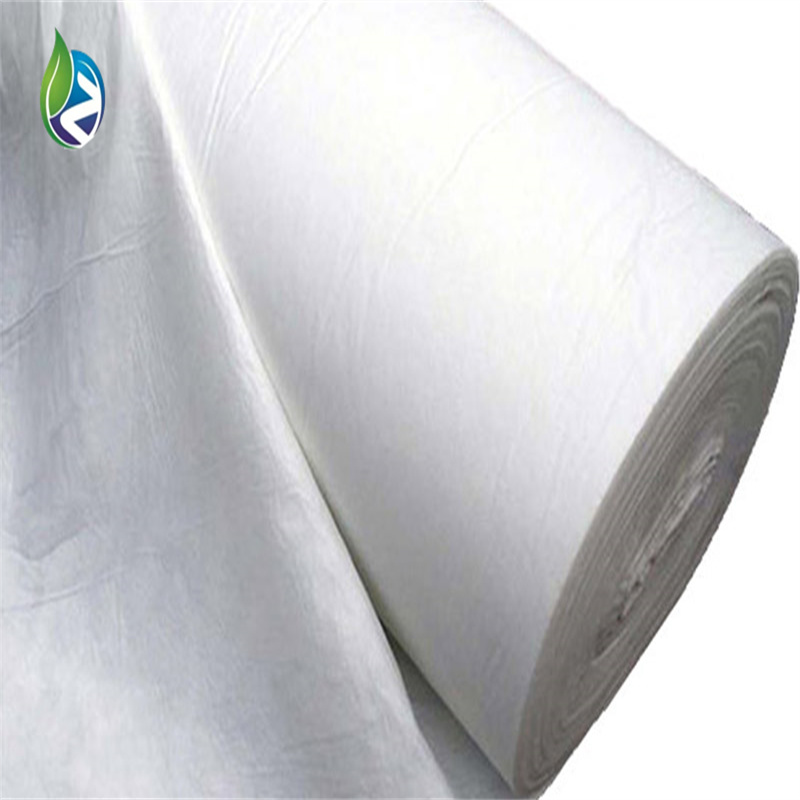

Filament Nonwoven Geotextile

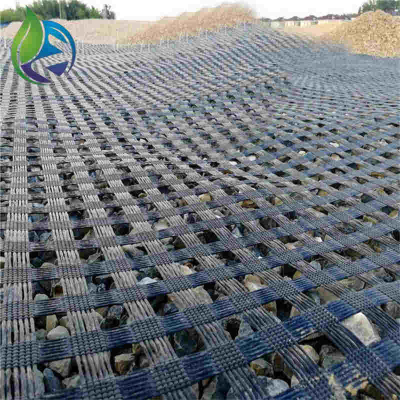

Geotextile synthetic materials refer to polymer materials or polymer engineering materials used in geotechnical engineering and civil engineering, which are widely used in many fields such as water conservancy, dam, road construction, airport, construction, environmental protection and so on. Long silk spunbonded needled nonwoven geotextile

It is one of the main products in geosynthetic materials, which can play the role of filtration, drainage, isolation, protection and strengthening in engineering.

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

When it comes to modern infrastructure and civil engineering, Filament Needle Punched Nonwoven Geotextile is one material that quietly does the heavy lifting—literally. From stabilizing roads to filtering water in drainage systems, this geotextile is trusted for its strength, flexibility, and durability.

But what makes filament needle punched nonwoven geotextile stand out? Let’s dive into why this fabric is becoming the go-to solution in construction, landscaping, and geotechnical projects.

What Is Filament Needle Punched Nonwoven Geotextile?

Filament needle punched nonwoven geotextile is made from continuous polyester or polypropylene filaments that are mechanically bonded using a needle punching technique. This process interlocks the fibers, creating a durable, flexible, and porous fabric that serves multiple purposes—filtration, separation, reinforcement, and drainage.

Unlike woven geotextiles, filament needle punched nonwoven geotextile offers greater water permeability and is less likely to clog over time, making it ideal for long-term projects in various environmental conditions.

Key Benefits of Filament Needle Punched Nonwoven Geotextile

1. ?️ Superior Strength and Durability

This geotextile withstands harsh installation conditions and heavy loads. Whether buried under highways or layered beneath embankments, it maintains its structure over time.

? “We used filament needle punched nonwoven geotextile beneath a railway project—excellent tensile strength, no tears during compaction!”

— @InfraEngineerMike

2. ? High Water Permeability

The needle-punched construction allows efficient water flow while blocking fine soil particles, making it perfect for drainage and filtration in wet environments.

? “It performed exceptionally well in our stormwater runoff project. Zero clogging after months of rain.”

— @DrainageProLisa

3. ? Environmental Compatibility

Made from chemically stable polymers, it resists biological and chemical degradation. It's also UV resistant when exposed temporarily, supporting long-term sustainability goals.

4. ? Easy to Transport & Install

Lightweight yet strong, filament needle punched nonwoven geotextile rolls are easy to handle, cut, and install—saving you time, labor, and money on-site.

Common Applications

Filament needle punched nonwoven geotextile is used across a wide range of sectors:

Road construction: Reinforcing roadbeds and preventing rutting

Railway stabilization: Increasing longevity under tracks

Drainage systems: Lining trenches, pipes, and retaining walls

Landfills: Used in liner and cap systems for leachate filtration

Pond and canal protection: Reduces erosion and sediment loss

Retaining walls: Improves slope stability and load distribution

Agriculture: Used for subsoil water drainage in fields

Technical Considerations When Buying

Choosing the right filament needle punched nonwoven geotextile depends on your project’s needs. Key specifications include:

GSM (grams per square meter): Higher GSM offers greater strength. Ranges from 100 to 800 gsm.

Tensile Strength: Look for ≥8kN/m for road and heavy-duty use.

Elongation Rate: Should balance flexibility and strength (40–100%).

Permittivity: Indicates water flow rate—important for drainage efficiency.

Puncture Resistance: Higher resistance is critical for rough or rocky terrain.

Always request data sheets or test reports from certified labs to ensure the quality of your chosen filament needle punched nonwoven geotextile.

Real-World Feedback from Professionals

⭐️⭐️⭐️⭐️⭐️

“Game changer for road projects”

"We laid this under a 2 km highway stretch in Malaysia. Five years later, no rutting or drainage issues. Totally worth the investment."

— @BuildAsiaTech

⭐️⭐️⭐️⭐️⭐️

“Reliable in agricultural use”

"Installed in vineyard trenches to manage seasonal runoff—keeps the soil intact and roots dry. Love how easy it is to work with."

— @VineyardInfraSolutions

⭐️⭐️⭐️⭐️

“Durable even in rocky terrain”

"Used it in a landfill cap system over rough fill—zero tears, strong bonding even during compaction."

— @GeoCoverEngineer

How to Install Filament Needle Punched Nonwoven Geotextile

Grade and level the base surface.

Unroll the geotextile fabric across the area, ensuring it's wrinkle-free.

Overlap adjoining sheets by 20–30 cm (or as required).

Secure using pins or backfill to prevent shifting during installation.

Cover immediately with gravel, soil, or additional geosynthetics.

Simple, efficient, and no special equipment needed.

Why Choose Filament Needle Punched Nonwoven Geotextile?

Because it does more than just sit underground—it protects your investment. With proper selection and installation, filament needle punched nonwoven geotextile can extend the life of your structure by decades. It's cost-effective, field-tested, and trusted by engineers globally.

Final Thoughts

If you're planning a project involving soil stabilization, drainage, or filtration, filament needle punched nonwoven geotextile should be at the top of your materials list. With its high tensile strength, longevity, and versatility, it's one of the smartest investments you can make in your groundwork.