High Density Pond Liner

As global industries expand their demand for reliable water containment systems, the importance of a High Density Pond Liner continues to grow. This liner type has become the preferred solution in aquaculture farms, municipal water projects, mining operations, and agricultural irrigation systems. Its superior chemical resistance, tensile strength, and long-term durability make it a strategic choice for B2B buyers seeking dependable waterproofing solutions.

This article analyzes the market background, technical specifications, manufacturing processes, and industry trends associated with High Density Pond Liners. It also provides essential insights for international buyers looking to source high-performance geomembranes for large-scale engineering projects.

High Density Pond Liner: Performance, Applications, and Key Considerations for Industrial Water Containment

As global industries expand their demand for reliable water containment systems, the importance of a High Density Pond Liner continues to grow. This liner type has become the preferred solution in aquaculture farms, municipal water projects, mining operations, and agricultural irrigation systems. Its superior chemical resistance, tensile strength, and long-term durability make it a strategic choice for B2B buyers seeking dependable waterproofing solutions.

This article analyzes the market background, technical specifications, manufacturing processes, and industry trends associated with High Density Pond Liners. It also provides essential insights for international buyers looking to source high-performance geomembranes for large-scale engineering projects.

Global Market Background and Demand Growth

The demand for efficient water management systems is rising due to increased industrial activity, environmental regulations, and climate-driven water scarcity. High Density Pond Liners play a key role in containment systems where leakage prevention and structural stability are critical. The market is expected to grow steadily over the next decade, with major adoption in Asia-Pacific, South America, and Africa—regions actively expanding aquaculture and infrastructure projects.

International engineering companies and contractors increasingly prefer high-density liners due to their cost-efficiency and long lifespan compared to low-density alternatives. This shift reflects a broader trend toward sustainable and low-maintenance construction materials.

Technical Characteristics of High Density Pond Liners

Material Strength and Durability

The High Density Pond Liner is typically produced from high-density polyethylene (HDPE), known for its rigidity, high tensile strength, and resistance to environmental stress cracking. These characteristics ensure maximum stability in reservoirs, landfills, and wastewater systems where long-term containment is essential.

Chemical and UV Resistance

One of the key advantages of high-density liners is their superior resistance to chemicals, acids, alkalis, and biological agents. This makes them suitable for industrial reservoirs, sewage systems, and hazardous containment areas. Additionally, UV-stabilized material ensures long-term performance under direct sunlight.

Impermeability and Sealing Performance

The primary function of a High Density Pond Liner is to create an impermeable barrier that prevents seepage into soil and groundwater. Advanced extrusion and calendaring manufacturing processes ensure uniform thickness and integrity across the entire liner sheet. Seam welding techniques, including extrusion welding or hot wedge welding, further enhance leakproof performance.

Manufacturing and Quality Control Standards

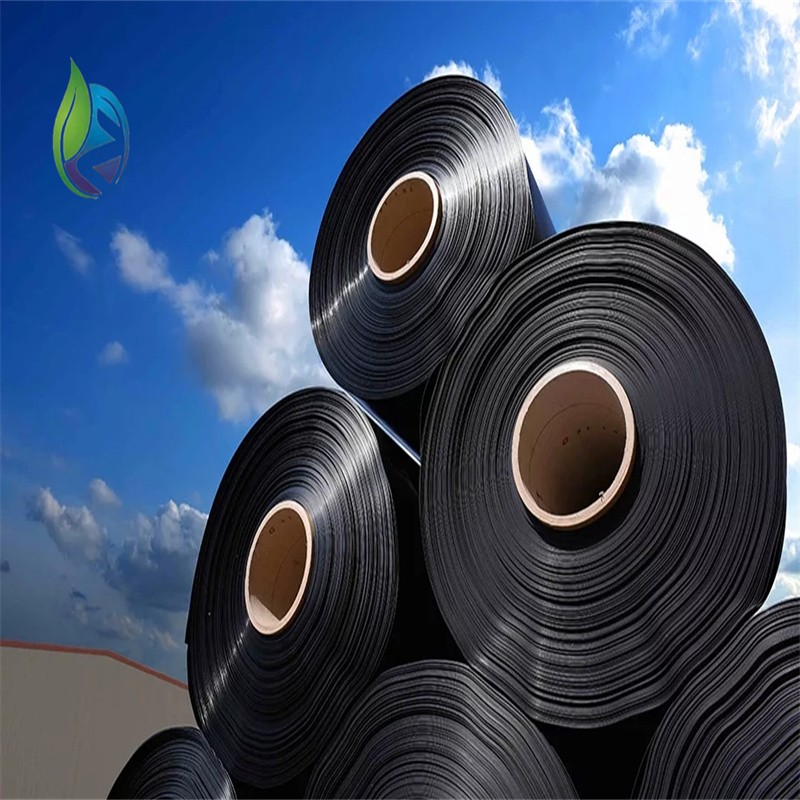

High Density Pond Liners are produced through extrusion blow molding or flat extrusion technology. During production, resin pellets are melted and formed into sheets of precise thickness—typically ranging from 0.5 mm to 2.0 mm depending on project requirements.

Quality control includes: - Tensile testing - Elongation testing - Tear resistance and puncture resistance analysis - Thickness uniformity checks - UV aging and oxidative induction time (OIT) testing

These tests ensure the liner meets international standards such as ASTM and ISO, which are essential for buyers managing large infrastructure or environmental protection projects.

Key Applications of High Density Pond Liners

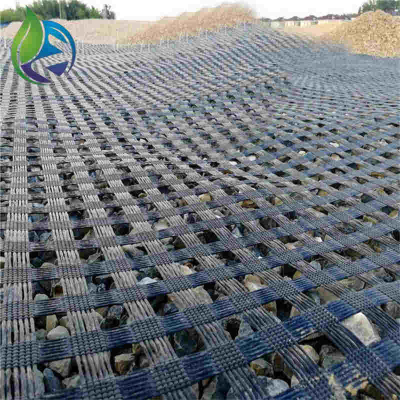

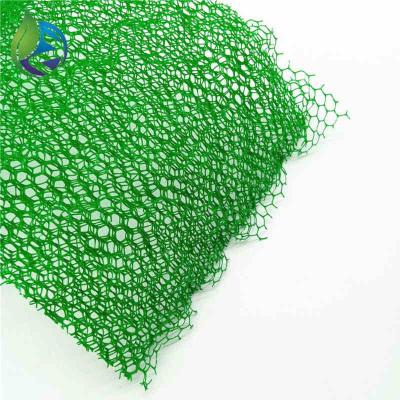

Due to their strong mechanical and chemical properties, High Density Pond Liners are suitable for:

Aquaculture ponds and fish farms

Mining tailings containment

Landfill base liners and capping systems

Industrial wastewater treatment systems

Evaporation ponds and chemical storage areas

These applications require stable, long-lasting liners capable of withstanding pressure, chemical exposure, and environmental challenges.

Market Trends and Strategic Insights for Buyers

Several trends are shaping the future of High Density Pond Liners:

1. **Sustainability requirements:** Governments and industries prefer liners that reduce environmental impact and ensure safe water containment. 2. **Thicker liner adoption:** Increasing installation of high-risk containment structures is pushing demand for 1.5 mm and 2.0 mm liners. 3. **Advanced welding technologies:** More projects require higher seam peel strength and shear resistance, improving long-term reliability. 4. **Customization options:** Buyers increasingly request roll-to-roll customization, pre-welded panels, and on-site installation support.

Frequently Asked Questions

1. What thickness is ideal for a High Density Pond Liner?

The ideal thickness depends on the application. Aquaculture ponds typically use 0.75–1.0 mm liners, while industrial or hazardous containment areas require 1.5–2.0 mm for maximum protection.

2. Can High Density Pond Liners be used in harsh chemical environments?

Yes. High-density polyethylene provides excellent resistance to acids, alkalis, and industrial wastewater, making it suitable for chemically aggressive environments.

3. What are the installation requirements?

Proper subgrade preparation, controlled welding, and field quality testing are essential. Professional installation ensures longevity and optimal sealing performance.

4. How long does a High Density Pond Liner last?

With UV stabilization and proper installation, the lifespan can exceed 20–25 years depending on the environmental conditions and liner thickness.

Conclusion and Professional Call to Action

A High Density Pond Liner is a critical component in modern water containment engineering, offering unmatched durability, impermeability, and chemical resistance. For international B2B buyers, choosing a supplier offering precise manufacturing standards, customization options, and long-term product reliability is essential.

We supply high-performance pond liners tailored for industrial, agricultural, and environmental projects. Contact us today to discuss specifications, request samples, or obtain a customized quotation for large-scale procurement.