LDPE Geomembrane

Manufacturing Process

The production of LDPE Geomembrane follows controlled engineering procedures to ensure uniformity and compliance.

Raw material batching and gravimetric dosing

High-temperature extrusion using flat-die or blown-film lines

Calendering or air-ring thickness control

Online thickness and surface inspection

Controlled cooling and edge trimming

Roll winding and labeling

Quality testing: tensile, elongation, puncture, and density checks

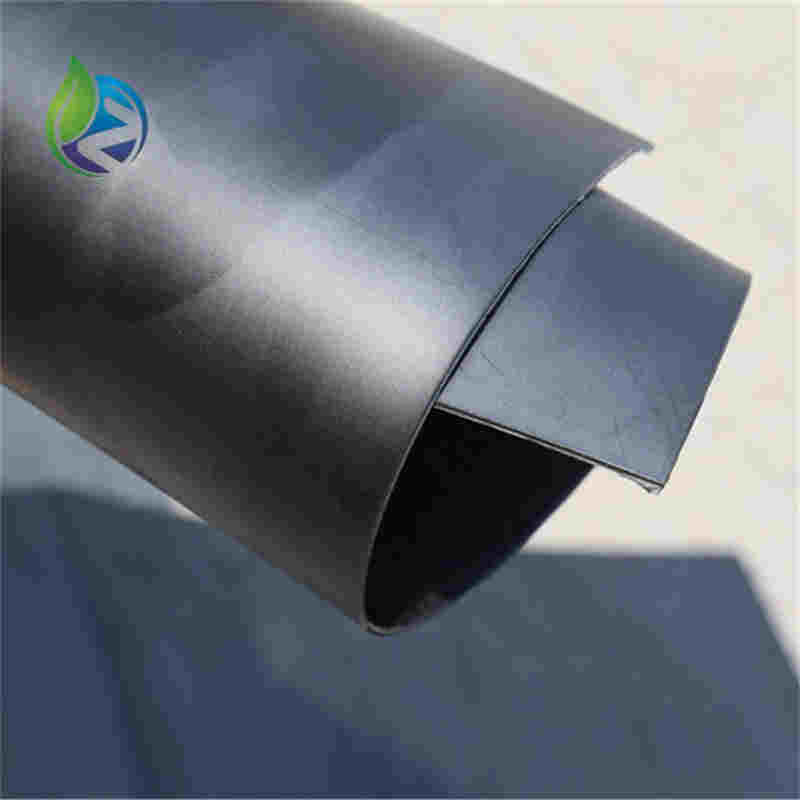

Product Definition

LDPE Geomembrane is a low-density polyethylene impermeable lining material engineered for fluid containment, seepage control, and environmental protection in civil and industrial projects. It offers high flexibility, chemical resistance, and adaptability to complex substrates.

Technical Parameters and Specifications

LDPE Geomembrane specifications are designed to meet international engineering and environmental standards.

Thickness: 0.3 mm – 3.0 mm

Density: 0.915 – 0.930 g/cm³

Tensile Strength at Yield: ≥ 8 MPa

Elongation at Break: ≥ 600%

Puncture Resistance: ≥ 300 N

Carbon Black Content: 2.0% – 3.0%

Service Temperature Range: -40°C to +60°C

Standard Width: 5.8 m – 8.0 m

Roll Length: 50 m – 200 m

Structure and Material Composition

LDPE Geomembrane is composed of a single-layer or co-extruded polymer structure optimized for flexibility and durability.

Base Resin: Virgin LDPE polymer for consistent mechanical properties

Carbon Black: UV stabilization and aging resistance

Antioxidants: Thermal and oxidative stability

Processing Additives: Improved extrusion flow and surface finish

Manufacturing Process

The production of LDPE Geomembrane follows controlled engineering procedures to ensure uniformity and compliance.

Raw material batching and gravimetric dosing

High-temperature extrusion using flat-die or blown-film lines

Calendering or air-ring thickness control

Online thickness and surface inspection

Controlled cooling and edge trimming

Roll winding and labeling

Quality testing: tensile, elongation, puncture, and density checks

Industry Comparison

| Material | Flexibility | Chemical Resistance | Cost Level | Typical Applications |

|---|---|---|---|---|

| LDPE Geomembrane | High | Good | Medium | Landfills, ponds, canals |

| HDPE Geomembrane | Moderate | Excellent | Medium-High | Hazardous waste, mining |

| PVC Geomembrane | Very High | Moderate | Low-Medium | Decorative ponds, roofing |

| EPDM | Very High | Good | High | Water features |

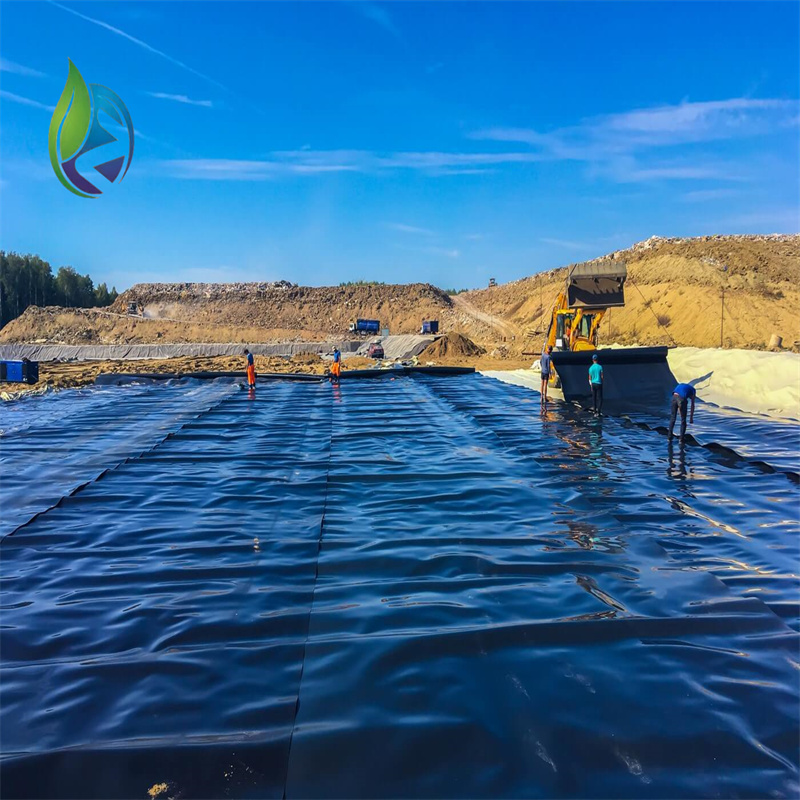

Application Scenarios

LDPE Geomembrane is widely adopted by EPC contractors, distributors, and engineering firms in:

Municipal and industrial landfill liners

Wastewater treatment lagoons

Agricultural irrigation canals and reservoirs

Mining heap leach pads

Temporary containment systems

Secondary containment for chemical storage

Core Engineering Pain Points and Solutions

Subgrade irregularity: High elongation accommodates settlement

Crack propagation: LDPE flexibility reduces stress concentration

Installation speed: Wider rolls minimize welding seams

Environmental exposure: UV-stabilized formulation extends service life

Risk Warnings and Mitigation Recommendations

Avoid prolonged exposure to sharp aggregates without cushioning layers

Ensure certified welding technicians perform seam joining

Conduct vacuum box or air pressure seam testing

Do not use recycled-content liners for critical containment

Procurement and Selection Guide

Define application environment and chemical exposure

Select appropriate thickness based on load and risk

Verify compliance with ASTM or equivalent standards

Confirm roll dimensions for site logistics

Request third-party quality test reports

Evaluate supplier engineering support capabilities

Plan installation and QA/QC procedures

Engineering Case Application

In a municipal wastewater lagoon project, 1.5 mm LDPE Geomembrane was installed over a compacted clay subgrade with geotextile protection. The liner accommodated differential settlement while maintaining hydraulic integrity, reducing seepage losses and long-term maintenance costs.

Frequently Asked Questions (FAQ)

What is the typical lifespan of LDPE Geomembrane? — 20–30 years under proper conditions.

Is LDPE Geomembrane suitable for potable water? — Yes, with certified formulations.

Can LDPE Geomembrane be welded? — Yes, using hot wedge or extrusion welding.

How does LDPE compare to HDPE? — LDPE is more flexible but less rigid.

What thickness is common for landfills? — Typically 1.5–2.0 mm.

Is UV resistance adequate? — Yes, with proper carbon black content.

Can it be installed in cold climates? — Installation is feasible above -10°C.

Does it resist acids and alkalis? — Yes, for most industrial chemicals.

Is custom sizing available? — Standard practice for large projects.

What QA tests are required? — Tensile, elongation, puncture, and seam testing.

Call to Action

For detailed technical datasheets, engineering consultation, project references, or quotation requests for LDPE Geomembrane, please contact our technical sales team with your project specifications.

E-E-A-T Author Credentials

This content is prepared by a geosynthetics engineering specialist with over 12 years of experience in geomembrane design, manufacturing quality control, and international EPC project support across environmental, mining, and infrastructure sectors.