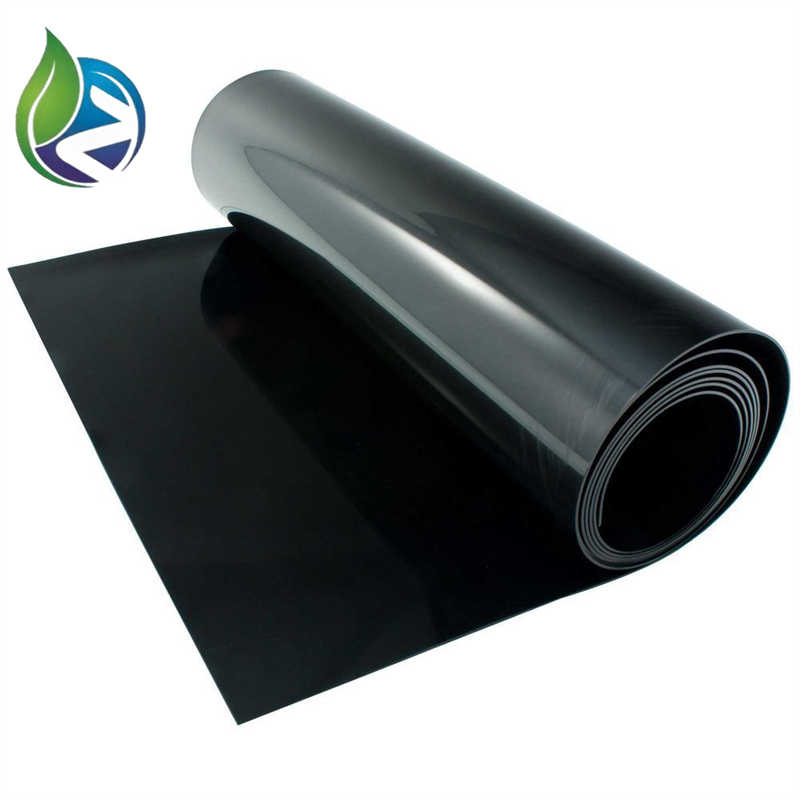

Low Density Polyethylene Geomembrane

Manufacturing Process

Low Density Polyethylene Geomembrane production follows a controlled, industrial extrusion process.

Raw material inspection and formulation batching

High-temperature extrusion using flat-die or blown-film extrusion lines

Online thickness monitoring via automatic gauge control

Calendering or air-ring cooling to stabilize sheet structure

Surface treatment and edge trimming

Roll winding under controlled tension

Finished product testing for mechanical and physical properties

Product Definition

Low Density Polyethylene Geomembrane is a flexible polymeric barrier manufactured from LDPE resin, designed for seepage control, liquid containment, and environmental protection in civil, mining, agricultural, and industrial engineering projects requiring high elongation and adaptability.

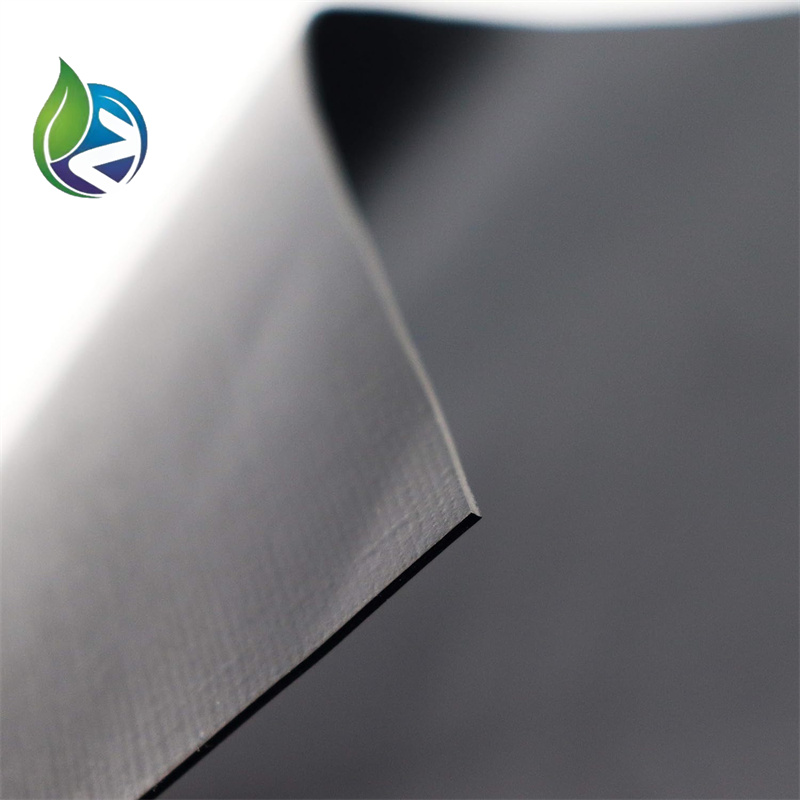

Technical Parameters and Specifications

Low Density Polyethylene Geomembrane is engineered to meet common international geosynthetics performance requirements for containment and lining systems.

Thickness Range: 0.3 mm – 3.0 mm

Density: 0.915 – 0.930 g/cm³

Tensile Strength at Yield: ≥ 8 MPa

Tensile Strength at Break: ≥ 10 MPa

Elongation at Break: ≥ 600%

Puncture Resistance: ≥ 300 N

Tear Resistance: ≥ 150 N

Carbon Black Content: 2.0% – 3.0%

Oxidative Induction Time (OIT): ≥ 100 minutes

Service Temperature: -40°C to +60°C

Standard Roll Width: 5.8 m – 8.0 m

Roll Length: 50 m – 200 m

Structure and Material Composition

The structural composition of Low Density Polyethylene Geomembrane focuses on flexibility, durability, and resistance to environmental stress cracking.

LDPE Base Resin: Virgin polyethylene ensuring stable mechanical properties

Carbon Black: UV protection and long-term aging resistance

Antioxidants: Thermal and oxidative stability during service life

Processing Additives: Improve melt flow, thickness uniformity, and surface finish

Manufacturing Process

Low Density Polyethylene Geomembrane production follows a controlled, industrial extrusion process.

Raw material inspection and formulation batching

High-temperature extrusion using flat-die or blown-film extrusion lines

Online thickness monitoring via automatic gauge control

Calendering or air-ring cooling to stabilize sheet structure

Surface treatment and edge trimming

Roll winding under controlled tension

Finished product testing for mechanical and physical properties

Industry Comparison

| Material Type | Flexibility | Chemical Resistance | Stress Crack Resistance | Relative Cost | Typical Use |

|---|---|---|---|---|---|

| Low Density Polyethylene Geomembrane | High | Good | High | Medium | Landfills, ponds, canals |

| HDPE Geomembrane | Moderate | Excellent | Moderate | Medium-High | Hazardous waste, mining |

| LLDPE Geomembrane | Very High | Good | Very High | Medium | Irregular subgrades |

| PVC Geomembrane | Very High | Moderate | Low | Low-Medium | Decorative lining |

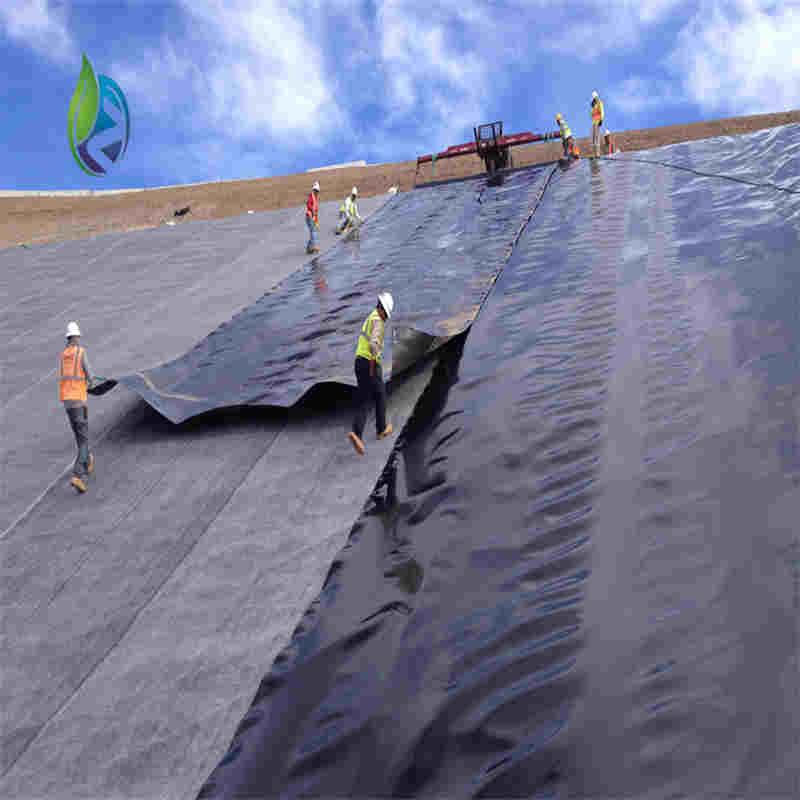

Application Scenarios

Low Density Polyethylene Geomembrane is widely specified by distributors, EPC contractors, and engineering firms for:

Municipal solid waste and industrial landfill lining systems

Wastewater treatment ponds and lagoons

Agricultural reservoirs and irrigation canals

Mining heap leach pads and tailings containment

Temporary containment and secondary spill protection

Water storage ponds for industrial facilities

Core Engineering Pain Points and Solutions

Uneven subgrade settlement: High elongation reduces liner cracking risk

Complex geometry installation: Flexible sheets adapt to slopes and curves

Seam failure risk: Compatible with hot wedge and extrusion welding systems

UV and aging exposure: Stabilized formulation extends outdoor service life

Risk Warnings and Mitigation Recommendations

Install protective geotextile layers over coarse or angular subgrades

Use certified welding technicians and calibrated equipment

Perform non-destructive seam testing on all welded joints

Avoid using non-certified recycled materials for critical containment

Control installation temperature to ensure proper seam fusion

Procurement and Selection Guide

Identify application type and chemical exposure conditions

Determine required thickness based on load and regulatory standards

Confirm compliance with ASTM, GRI, or equivalent specifications

Select roll dimensions based on site logistics and installation plan

Request third-party laboratory test reports

Evaluate supplier manufacturing capability and quality control

Assess availability of technical support and installation guidance

Engineering Case Application

In an industrial wastewater lagoon project, a 1.5 mm Low Density Polyethylene Geomembrane liner was installed over a compacted soil subgrade with nonwoven geotextile cushioning. The system accommodated differential settlement and temperature variation, achieving long-term seepage control and regulatory compliance.

Frequently Asked Questions (FAQ)

What is the typical service life? — 20–30 years under normal exposure.

Is it suitable for potable water storage? — Yes, with certified resin formulations.

Can it be welded on site? — Yes, using hot wedge or extrusion welding.

How does it differ from HDPE geomembrane? — LDPE offers higher flexibility.

What thickness is common for ponds? — Typically 1.0–1.5 mm.

Is UV resistance adequate? — Yes, with proper carbon black content.

Can it handle cold climates? — Installation is feasible above -10°C.

Is it resistant to acids and alkalis? — Resistant to most common chemicals.

Are custom roll sizes available? — Common for large-scale projects.

What quality tests are required? — Tensile, elongation, puncture, and seam tests.

Call to Action

For project-specific quotations, technical datasheets, engineering consultation, or material samples of Low Density Polyethylene Geomembrane, please submit your application details to our technical sales team.

E-E-A-T Author Credentials

This article is authored by a geosynthetics engineering professional with over 10 years of experience in geomembrane manufacturing, quality assurance, and EPC project support across environmental, infrastructure, and mining applications.