LDPE Agricultural Geomembrane

Manufacturing Process

LDPE Agricultural Geomembrane is produced using controlled industrial extrusion processes to ensure consistent quality.

Incoming raw material inspection and formulation design

Automatic batching and gravimetric feeding

High-temperature flat-die or blown-film extrusion

Online thickness monitoring and surface inspection

Controlled cooling and calendering

Edge trimming and roll winding

Finished product testing for mechanical and physical properties

Product Definition

LDPE Agricultural Geomembrane is a low-density polyethylene impermeable liner engineered specifically for agricultural water management, soil protection, and containment applications, offering high flexibility, chemical stability, and long-term resistance to outdoor environmental exposure.

Technical Parameters and Specifications

LDPE Agricultural Geomembrane is designed to meet practical agricultural engineering requirements while maintaining consistent physical performance.

Thickness Range: 0.3 mm – 2.0 mm

Density: 0.915 – 0.930 g/cm³

Tensile Strength at Yield: ≥ 8 MPa

Tensile Strength at Break: ≥ 10 MPa

Elongation at Break: ≥ 600%

Puncture Resistance: ≥ 250 N

Tear Resistance: ≥ 120 N

Carbon Black Content: 2.0% – 3.0%

UV Resistance: ≥ 80% strength retention after accelerated aging

Service Temperature Range: -40°C to +60°C

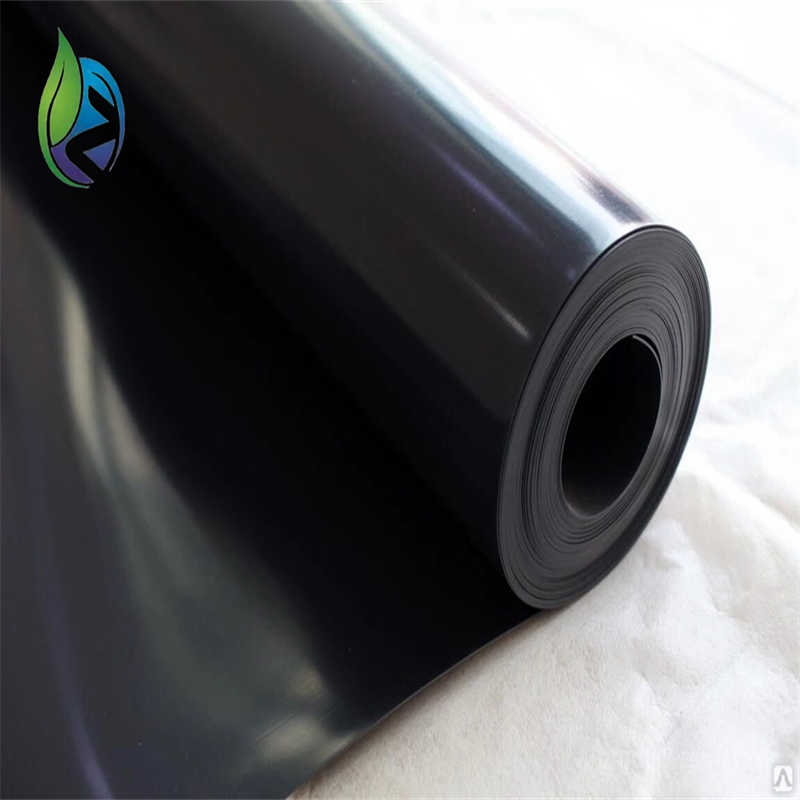

Standard Roll Width: 4.0 m – 8.0 m

Roll Length: 50 m – 200 m

Structure and Material Composition

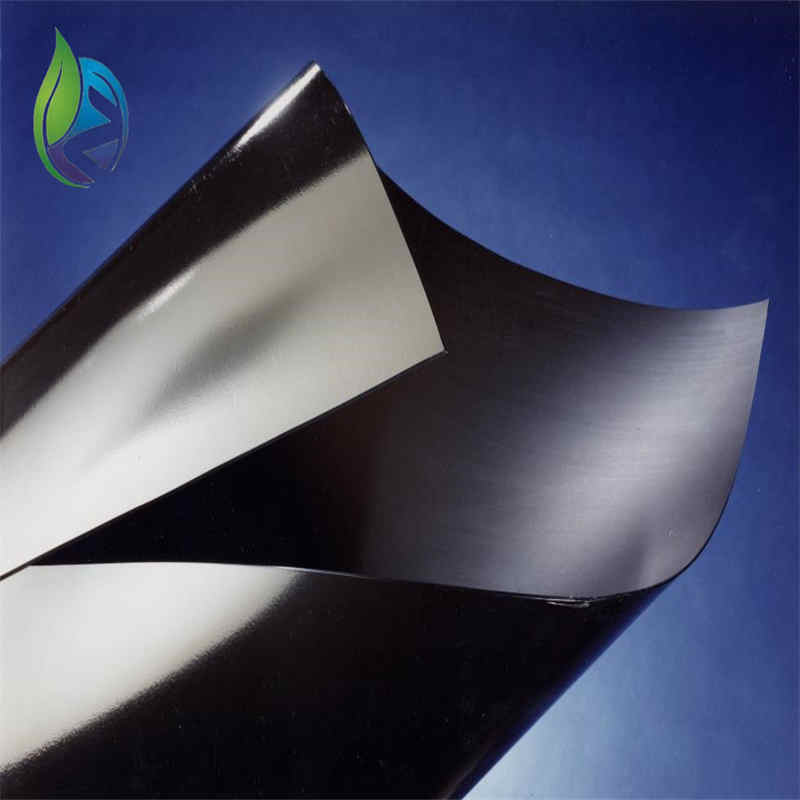

The material structure of LDPE Agricultural Geomembrane prioritizes flexibility and durability under variable soil and climate conditions.

LDPE Base Resin: Virgin low-density polyethylene for uniform mechanical behavior

Carbon Black: Provides UV stabilization and weathering resistance

Antioxidants: Delay thermal and oxidative degradation during service life

Processing Additives: Improve extrusion stability and thickness consistency

Manufacturing Process

LDPE Agricultural Geomembrane is produced using controlled industrial extrusion processes to ensure consistent quality.

Incoming raw material inspection and formulation design

Automatic batching and gravimetric feeding

High-temperature flat-die or blown-film extrusion

Online thickness monitoring and surface inspection

Controlled cooling and calendering

Edge trimming and roll winding

Finished product testing for mechanical and physical properties

Industry Comparison

| Material | Flexibility | UV Resistance | Chemical Stability | Relative Cost | Typical Agricultural Use |

|---|---|---|---|---|---|

| LDPE Agricultural Geomembrane | High | Good | Good | Medium | Ponds, canals, reservoirs |

| HDPE Geomembrane | Moderate | Excellent | Excellent | Medium-High | Large reservoirs, waste ponds |

| LLDPE Geomembrane | Very High | Good | Good | Medium | Uneven agricultural terrain |

| PVC Liner | Very High | Moderate | Moderate | Low-Medium | Small decorative ponds |

Application Scenarios

LDPE Agricultural Geomembrane is widely used by agricultural distributors, EPC contractors, and engineering teams in:

Irrigation water storage ponds and farm reservoirs

Agricultural canal lining and seepage control

Aquaculture ponds and fish farming systems

Biogas digesters and manure containment

Soil moisture conservation systems

Greenhouse water and nutrient containment

Core Engineering Pain Points and Solutions

Water seepage losses: Continuous impermeable barrier minimizes leakage

Uneven or soft subgrade: High elongation accommodates settlement

UV exposure: Stabilized formulation ensures outdoor durability

Complex installation geometry: Flexible sheets adapt to slopes and curves

Risk Warnings and Mitigation Recommendations

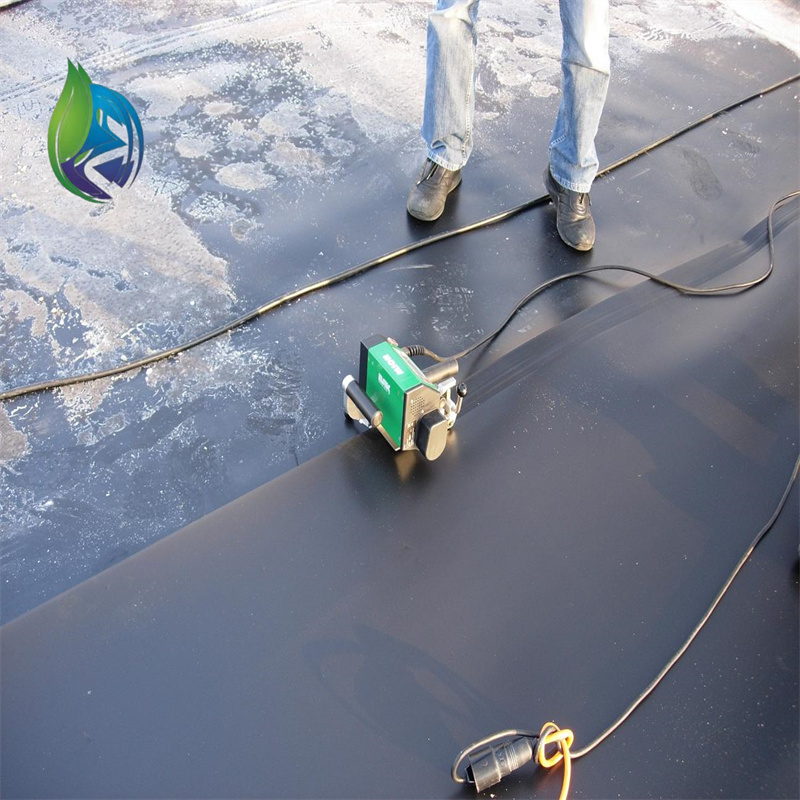

Install cushioning geotextiles over rocky or angular subgrades

Avoid dragging liner sheets across rough ground during installation

Ensure proper anchoring to prevent wind uplift

Perform seam testing on welded joints where applicable

Avoid prolonged exposure to open flame or sharp tools

Procurement and Selection Guide

Define agricultural application and expected service life

Select appropriate thickness based on water depth and soil conditions

Confirm UV stabilization requirements for local climate

Choose roll dimensions suitable for site layout

Request mechanical and aging test reports

Evaluate supplier production capacity and quality control

Plan installation method and maintenance strategy

Engineering Case Application

In a commercial aquaculture farm project, a 1.0 mm LDPE Agricultural Geomembrane was installed to line multiple fish ponds over compacted soil with protective geotextile underlay. The system reduced water loss, improved pond hygiene, and supported long-term operation with minimal maintenance.

Frequently Asked Questions (FAQ)

What is the typical lifespan in agricultural use? — 15–25 years depending on exposure.

Is LDPE Agricultural Geomembrane safe for aquaculture? — Yes, with compliant resin formulations.

Can it be welded on site? — Yes, using hot wedge or extrusion welding.

What thickness is common for farm ponds? — Usually 0.75–1.5 mm.

Is UV resistance necessary? — Essential for exposed agricultural applications.

Can it handle seasonal temperature changes? — Yes, within specified temperature range.

Is it resistant to fertilizers and manure? — Resistant to most agricultural chemicals.

Are custom sizes available? — Yes, for large-scale farm projects.

Does it require regular maintenance? — Minimal, with periodic inspection.

What tests ensure quality? — Tensile, elongation, puncture, and aging tests.

Call to Action

For pricing, technical datasheets, agricultural engineering consultation, or material samples of LDPE Agricultural Geomembrane, please submit your project requirements to our technical sales team for professional evaluation.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineer with over a decade of experience in agricultural lining systems, polymer material selection, and international EPC project support, ensuring technically accurate and procurement-oriented guidance.