Composite drainage board

Manufacturing Process

The manufacturing of composite drainage boards involves several key steps, ensuring a high-quality end product:

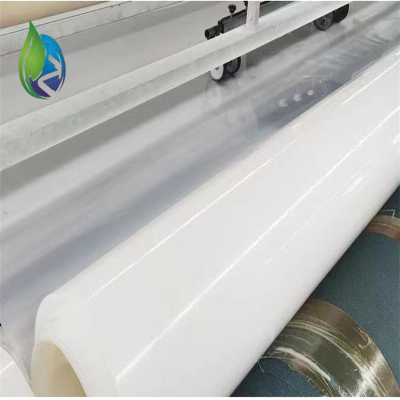

Material Selection: Choose high-density polyethylene and geotextile materials based on specific performance requirements.

Extrusion: HDPE is melted and extruded into sheets with perforations for water flow.

Geotextile Lamination: The non-woven geotextile is bonded to the HDPE sheet using a heat-lamination process.

Cutting and Shaping: The composite drainage board is cut into rolls or sheets based on the required dimensions.

Quality Testing: The finished product undergoes quality checks for compressive strength, flow rate, and durability.

Product Definition

The composite drainage board is a modern engineering material used for efficient water drainage in construction applications. Its unique structure and material composition make it ideal for foundation drainage, retaining wall applications, and landscaping projects.

Technical Parameters and Specifications

| Parameter | Specification |

|---|---|

| Thickness | 8–20 mm |

| Compressive Strength | ≥ 200 kPa |

| Water Flow Rate | ≥ 5 L/min |

| Material Composition | HDPE + Geotextile |

| Density | ≥ 1.3 g/cm³ |

| Length | 50–100 m |

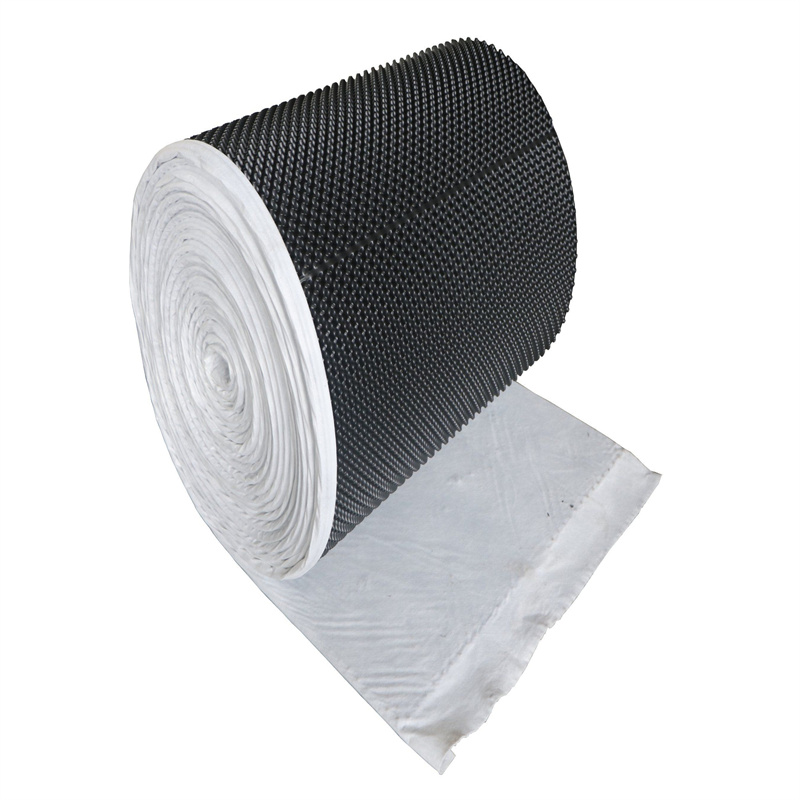

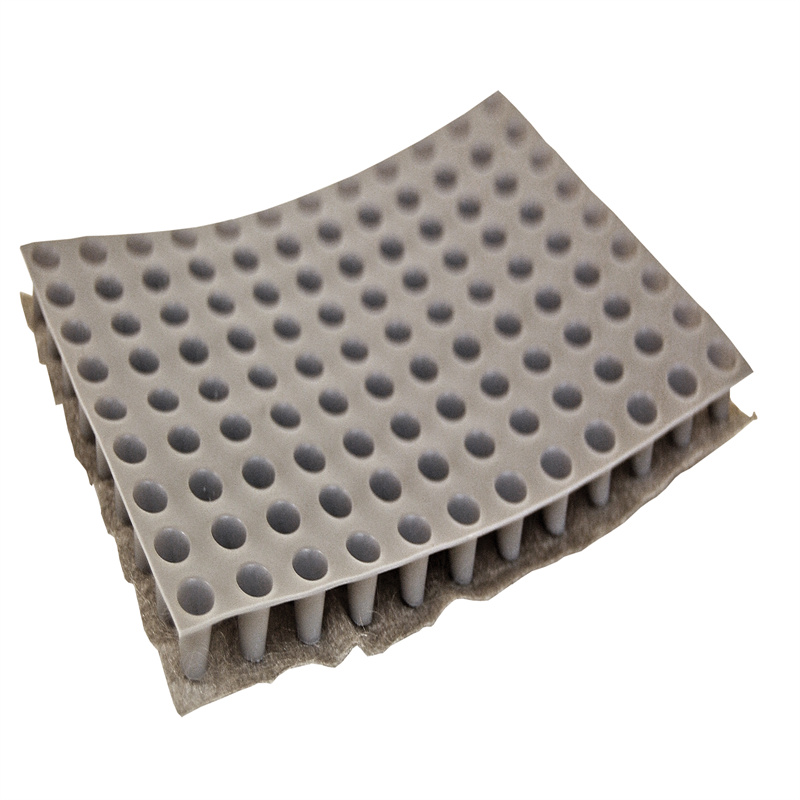

Structure and Material Composition

The composite drainage board typically consists of a high-density polyethylene (HDPE) core, which is perforated to allow efficient water flow. The surface is covered with a non-woven geotextile fabric that enhances filtration while providing structural support. The HDPE core ensures durability and resistance to external environmental pressures, making it suitable for long-term use in harsh conditions.

HDPE Core: Provides high compressive strength and resistance to chemicals.

Non-woven Geotextile: Enhances water filtration while preventing soil erosion.

Perforated Design: Allows for efficient water drainage across various terrains.

Manufacturing Process

The manufacturing of composite drainage boards involves several key steps, ensuring a high-quality end product:

Material Selection: Choose high-density polyethylene and geotextile materials based on specific performance requirements.

Extrusion: HDPE is melted and extruded into sheets with perforations for water flow.

Geotextile Lamination: The non-woven geotextile is bonded to the HDPE sheet using a heat-lamination process.

Cutting and Shaping: The composite drainage board is cut into rolls or sheets based on the required dimensions.

Quality Testing: The finished product undergoes quality checks for compressive strength, flow rate, and durability.

Industry Comparison

| Material | Composite Drainage Board | Conventional Drainage Pipe | Geotextile Fabric |

|---|---|---|---|

| Water Flow Rate | High (≥ 5 L/min) | Moderate | Low |

| Compressive Strength | High (≥ 200 kPa) | Low | Very Low |

| Durability | High (resistant to chemicals, UV) | Moderate | Low |

| Installation | Simple (rolls or sheets) | Complex (requires digging and joining pipes) | Simple (but less effective alone) |

Applications

Composite drainage boards are widely used in various construction and civil engineering projects. Their primary applications include:

Foundation Drainage: Used to prevent water accumulation around building foundations.

Retaining Walls: Applied in retaining wall systems to manage water pressure.

Landscaping: Effective in landscaping projects for water management.

Road Construction: Used in road base drainage systems to enhance soil stability.

Core Pain Points and Solutions

Pain Point: Insufficient drainage leading to water accumulation.

Solution: Composite drainage boards provide superior water flow rates, preventing water buildup.

Pain Point: Poor durability in harsh environments.

Solution: The high-density polyethylene material is resistant to chemical degradation and UV exposure.

Pain Point: Complicated installation procedures.

Solution: The drainage board is easy to install in rolls or sheets, simplifying labor costs.

Pain Point: Soil erosion in landscape applications.

Solution: The geotextile fabric prevents soil erosion while facilitating water filtration.

Risk Warnings and Precautionary Advice

While composite drainage boards are highly effective, it is important to consider the following risks:

Improper Installation: Ensure the board is installed correctly to prevent improper drainage.

UV Degradation: Ensure proper UV protection when used in direct sunlight for extended periods.

Soil Contamination: Avoid installation in areas with aggressive chemicals that may degrade the material.

Procurement and Selection Guide

Follow these 6 steps to ensure you select the right composite drainage board for your project:

Determine your water flow rate requirements.

Assess the compressive strength required for your project.

Check the material specifications for environmental resistance (UV, chemicals, etc.).

Choose the appropriate size based on the installation area.

Ensure compatibility with other drainage systems in use.

Consult with suppliers to verify the quality and performance standards.

Case Studies and Real-World Applications

Below is a real-world application of composite drainage board in a major construction project:

Project: Foundation Drainage for a High-Rise Building

Location: Urban Area with High Water Table

Challenge: Prevent water accumulation around building foundation.

Solution: Composite drainage boards were installed around the perimeter, reducing water pressure and enhancing the longevity of the structure.

Result: Improved foundation stability and water management.

FAQ

What is the lifespan of composite drainage boards? Typically, 25–30 years with proper installation and maintenance.

Can composite drainage boards be used in all climates? Yes, they are designed to withstand both hot and cold temperatures.

How do I install composite drainage boards? The boards can be rolled out along the installation area, ensuring proper overlap and sealing.

Are composite drainage boards environmentally friendly? Yes, they are made from recyclable materials and reduce water pollution.

Do composite drainage boards prevent soil erosion? Yes, the geotextile layer helps to control soil movement.

Can I use composite drainage boards for landscaping? Yes, they are commonly used in landscaping projects for water management.

How do composite drainage boards compare to traditional drainage pipes? They offer superior water flow rates, easier installation, and higher durability.

Are composite drainage boards cost-effective? Yes, they offer long-term savings by reducing installation time and labor costs.

Do composite drainage boards require maintenance? Minimal maintenance is required, primarily ensuring the drainage pathways remain clear.

Can composite drainage boards be used in road construction? Yes, they are commonly used in road base drainage to maintain soil stability.

Request a Quote

If you are interested in purchasing composite drainage boards or need more information, please contact us for a detailed quote, technical documents, or engineering samples.