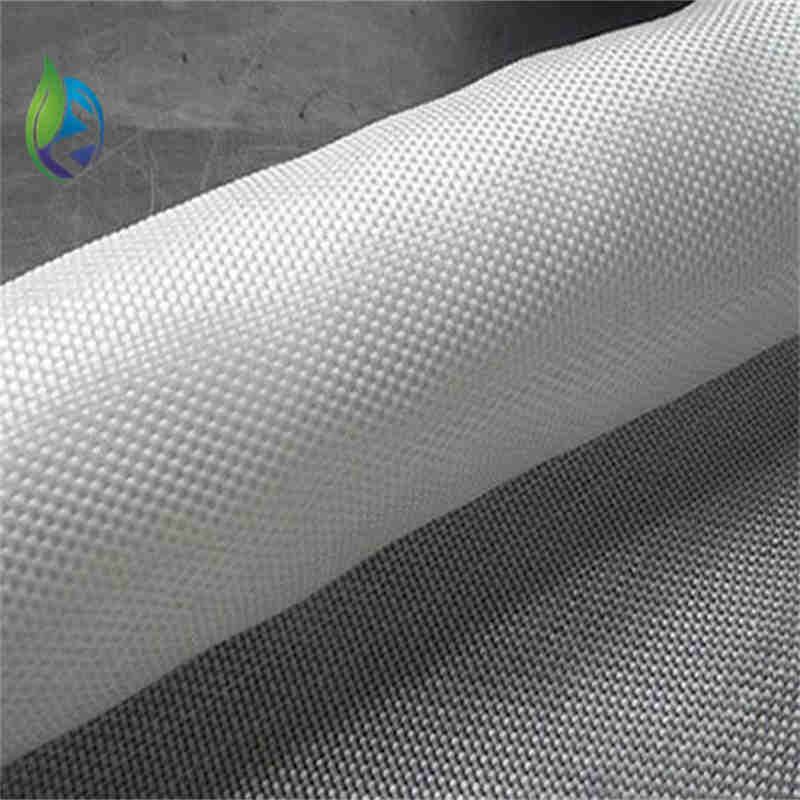

Filament Woven Geotextile

Manufacturing Process

Filament woven geotextile is produced using industrial textile manufacturing lines:

Polymer melting and filament extrusion

Filament drawing and orientation

Yarn winding and quality inspection

Warp and weft preparation

High-speed weaving on shuttle or rapier looms

Heat setting and dimensional stabilization

Surface inspection and mechanical testing

Roll cutting, labeling, and packaging

Product Definition

Filament woven geotextile is a high-strength geosynthetic manufactured from continuous polyester or polypropylene filaments woven into a stable fabric, designed to provide reinforcement, separation, and load distribution in civil and geotechnical engineering applications.

Technical Parameters and Specifications

Common engineering parameters for filament woven geotextile are as follows:

Raw material: Polyester (PET) or Polypropylene (PP)

Mass per unit area: 120 – 800 g/m²

Tensile strength (MD/XMD): 50 – 400 kN/m

Elongation at break: ≤ 15%

CBR puncture resistance: ≥ 6 – 20 kN

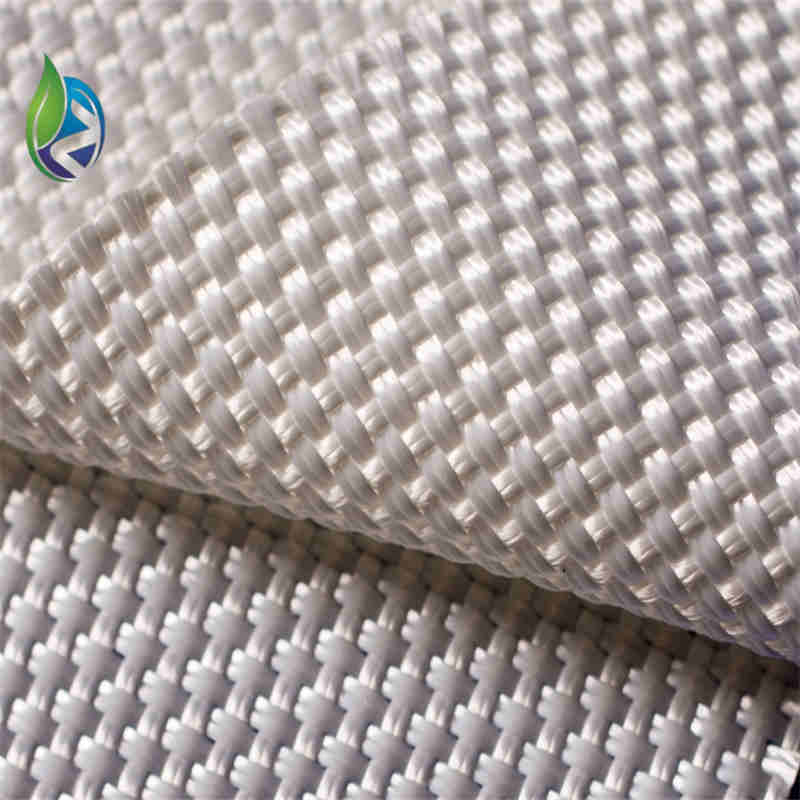

Equivalent opening size (O95): 0.05 – 0.40 mm

Permeability coefficient: ≥ 10⁻³ m/s

UV resistance: ≥ 70% retained strength after 500 hours

Design service life: ≥ 50 years (buried condition)

Structure and Material Composition

The performance of filament woven geotextile depends on its engineered textile structure:

Continuous Filament Yarns: Provide high tensile strength and low creep

Warp Direction (MD): Primary load-bearing axis

Weft Direction (XMD): Lateral stability and load distribution

Woven Interlacing: Controlled pore structure for filtration

Thermal or Chemical Stabilizers: Enhance durability and UV resistance

Manufacturing Process

Filament woven geotextile is produced using industrial textile manufacturing lines:

Polymer melting and filament extrusion

Filament drawing and orientation

Yarn winding and quality inspection

Warp and weft preparation

High-speed weaving on shuttle or rapier looms

Heat setting and dimensional stabilization

Surface inspection and mechanical testing

Roll cutting, labeling, and packaging

Industry Comparison

| Geotextile Type | Tensile Strength | Elongation | Filtration | Primary Function |

|---|---|---|---|---|

| Filament Woven Geotextile | Very High | Low | Controlled | Reinforcement & Separation |

| Staple Fiber Nonwoven | Medium | High | Excellent | Filtration & Drainage |

| Slit-Film Woven | High | Low | Poor | Separation |

| Knitted Geotextile | Medium | Medium | Good | Specialized Reinforcement |

Application Scenarios

Filament woven geotextile is widely specified by EPC contractors and engineers for:

Road and highway base reinforcement

Railway subgrade stabilization

Embankment and slope reinforcement

Port, quay, and coastal engineering

Retaining walls and mechanically stabilized earth

Airport pavement structures

Core Pain Points and Solutions

Pain Point: Subgrade deformation under heavy load

Solution: High tensile strength filament woven geotextile reinforcementPain Point: Soil mixing between layers

Solution: Stable woven structure ensuring separationPain Point: Long-term creep failure

Solution: Continuous filament yarns with low creep characteristicsPain Point: Construction damage during installation

Solution: High puncture and tear resistance

Risk Warnings and Mitigation

Key risks associated with filament woven geotextile use include:

Improper orientation: always align MD with primary load direction

Insufficient overlap: maintain ≥ 300 mm overlaps or as designed

UV exposure during storage: cover rolls before installation

Incorrect pore size selection: match soil gradation requirements

Procurement and Selection Guide

Define project loading and design life

Select required tensile strength and elongation

Match filtration criteria to soil properties

Confirm compliance with project specifications

Review third-party laboratory test reports

Evaluate supplier manufacturing capacity

Assess logistics, roll size, and packaging

Engineering Case Study

In a highway widening project, filament woven geotextile with tensile strength of 200 kN/m was installed between weak subgrade and crushed stone base. Plate load tests showed bearing capacity improvement of over 40%, and post-construction settlement remained within design limits after five years of service.

FAQ

What is the main function? Reinforcement and separation.

Is it suitable for soft soil? Yes, with proper design.

How long is the service life? Over 50 years when buried.

Can it be used underwater? Yes, with appropriate material selection.

What is MD direction? Machine direction with higher tensile strength.

Does it allow drainage? Limited but controlled permeability.

Is it resistant to chemicals? Yes, to most soil chemicals.

Can it replace geogrids? In some reinforcement applications.

What roll sizes are available? Customized based on project needs.

Does it require skilled installation? Standard geotextile installation practices apply.

Call to Action

To request pricing, technical datasheets, design support, or engineering samples of filament woven geotextile, please submit your project specifications for professional evaluation.

E-E-A-T Author Statement

This article is prepared by geotechnical engineers and materials specialists with over 20 years of experience in geosynthetics design, testing, and large-scale infrastructure projects worldwide.