Geocell for Road Subgrade Reinforcement

Manufacturing Process

Raw Material Compounding: Polymer resin blending with stabilizers

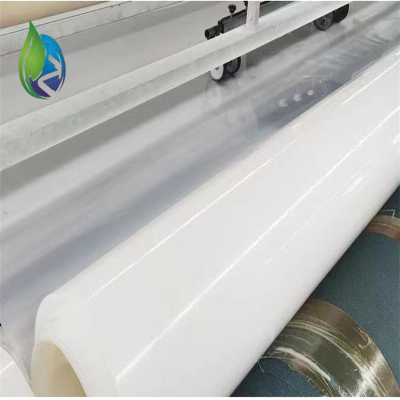

Sheet Extrusion: Precision extrusion to achieve uniform thickness

Strip Cutting: Automated cutting to design width and length

Ultrasonic Welding: CNC-controlled welding at specified intervals

Quality Inspection: Weld strength, tensile testing, dimensional checks

Folding & Packaging: Compact folding for transport efficiency

Product Definition

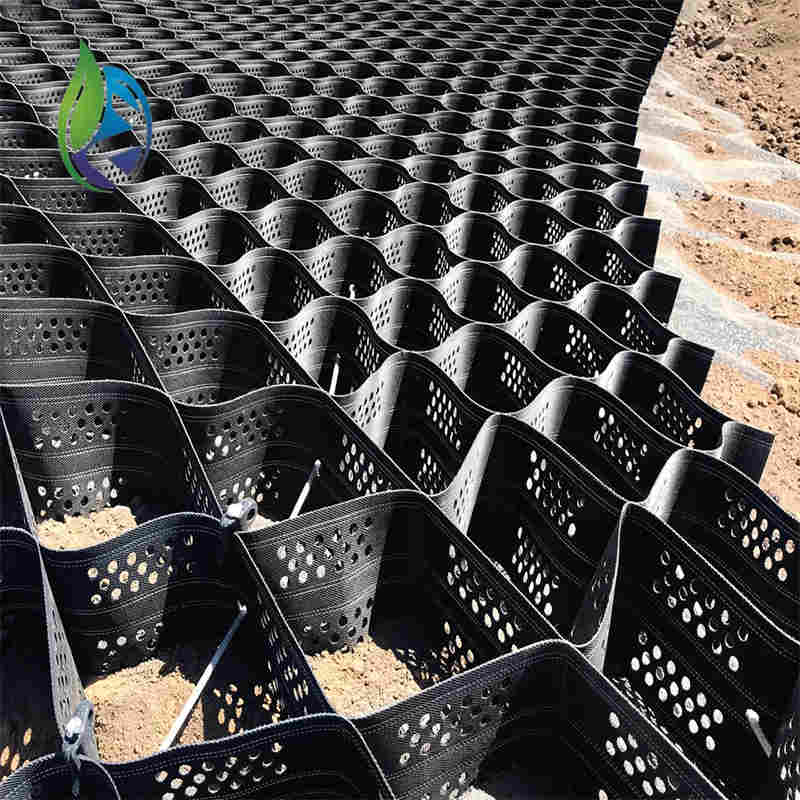

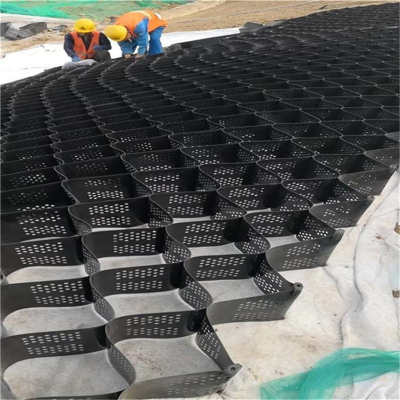

Geocell for Road Subgrade Reinforcement is a three-dimensional cellular confinement system made of polymer strips welded into a honeycomb structure, designed to improve bearing capacity, distribute loads, and control deformation in road subgrade engineering.

Technical Parameters and Specifications

Material type: HDPE or Novel Polymer Alloy (NPA)

Cell height: 50 mm / 75 mm / 100 mm / 150 mm / 200 mm

Cell size (expanded): 200 × 200 mm or 250 × 250 mm

Sheet thickness: 1.1–1.8 mm

Weld spacing: 330 mm / 356 mm / 445 mm

Weld peel strength: ≥1000 N/10 cm

Tensile strength at yield: ≥20 MPa

Environmental resistance: UV-stabilized, chemical and biological resistant

Design service life: ≥50 years (buried condition)

Structure and Material Composition

Geocell Strips: Extruded polymer sheets with controlled thickness

Ultrasonic Welds: High-strength bonding points forming cellular network

Cellular Matrix: Three-dimensional confinement structure after expansion

Anchoring Elements: Steel or polymer anchors for slope or subgrade fixation

Infill Materials: Gravel, crushed stone, sand, or stabilized soil

Manufacturing Process

Raw Material Compounding: Polymer resin blending with stabilizers

Sheet Extrusion: Precision extrusion to achieve uniform thickness

Strip Cutting: Automated cutting to design width and length

Ultrasonic Welding: CNC-controlled welding at specified intervals

Quality Inspection: Weld strength, tensile testing, dimensional checks

Folding & Packaging: Compact folding for transport efficiency

Industry Comparison

| Item | Geocell Reinforcement | Geogrid | Crushed Stone Thickening |

|---|---|---|---|

| Load Distribution | Three-dimensional confinement | Two-dimensional reinforcement | Passive |

| Settlement Control | Excellent | Moderate | Limited |

| Material Consumption | Reduced fill volume | Normal | High |

| Construction Efficiency | Fast modular installation | Layer-based | Labor intensive |

Application Scenarios

Highway and expressway subgrade reinforcement

Soft soil and weak foundation treatment

Rural and temporary access roads

Heavy-load industrial roads and logistics yards

EPC road infrastructure projects

Core Pain Points and Solutions

Excessive subgrade settlement: Geocell confinement increases modulus of base layer

Low bearing capacity on soft soil: Load dispersion reduces stress concentration

High maintenance costs: Reinforced structure extends pavement service life

Material transportation challenges: Allows use of locally available infill materials

Risk Warnings and Mitigation Measures

Insufficient welding strength may cause structural failure; verify test reports

Improper cell height selection can reduce reinforcement efficiency; match to traffic load

Inadequate infill compaction leads to deformation; follow layered compaction standards

UV exposure during storage; ensure covered storage before installation

Procurement and Selection Guide

Assess subgrade soil conditions and bearing capacity

Define traffic load class and design life

Select appropriate geocell height and sheet thickness

Confirm weld spacing and peel strength requirements

Verify compliance with relevant standards and testing data

Evaluate supplier manufacturing capability and project references

Engineering Case Study

In a heavy-duty logistics road project built on silty clay subgrade, a 150 mm high Geocell for Road Subgrade Reinforcement was installed over a geotextile separation layer and filled with crushed stone. Plate load tests showed an increase in bearing capacity from 120 kPa to over 260 kPa, while long-term settlement was reduced by approximately 40% after two years of operation.

FAQ

What infill materials are suitable? — Crushed stone, gravel, sand, or stabilized soil.

Is geocell suitable for heavy traffic roads? — Yes, with proper design parameters.

Does it replace geogrid? — It complements or replaces depending on design needs.

What is the typical installation thickness? — Usually one geocell layer per design.

Can it be used on slopes? — Yes, with anchoring systems.

How is quality verified on site? — Visual inspection and compaction testing.

What standards apply? — Commonly ASTM, ISO, or local highway specifications.

Is drainage affected? — No, open cells allow water movement.

What equipment is required? — Light machinery and standard compaction tools.

What is the expected service life? — Over 50 years in buried conditions.

Call to Action

For detailed technical datasheets, engineering design support, or quotation requests related to Geocell for Road Subgrade Reinforcement, please submit your project parameters to obtain tailored solutions and evaluation samples.

E-E-A-T Author Credentials

This content is prepared by civil engineering professionals with more than 15 years of experience in geosynthetics, road subgrade reinforcement, and infrastructure EPC projects, providing technical consulting and material evaluation for transportation developments worldwide.