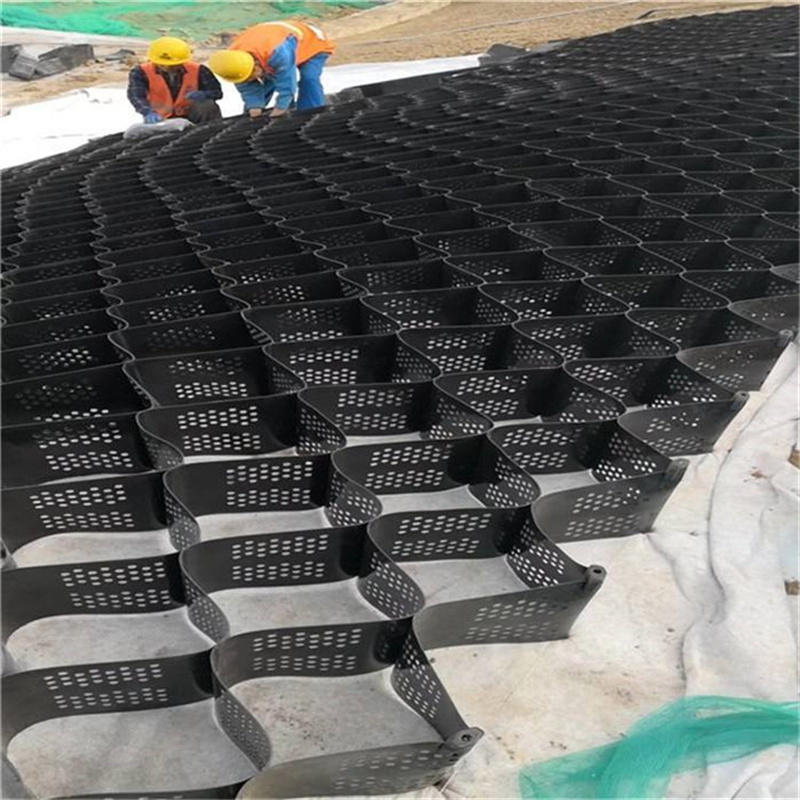

Geocell for road reinforcement

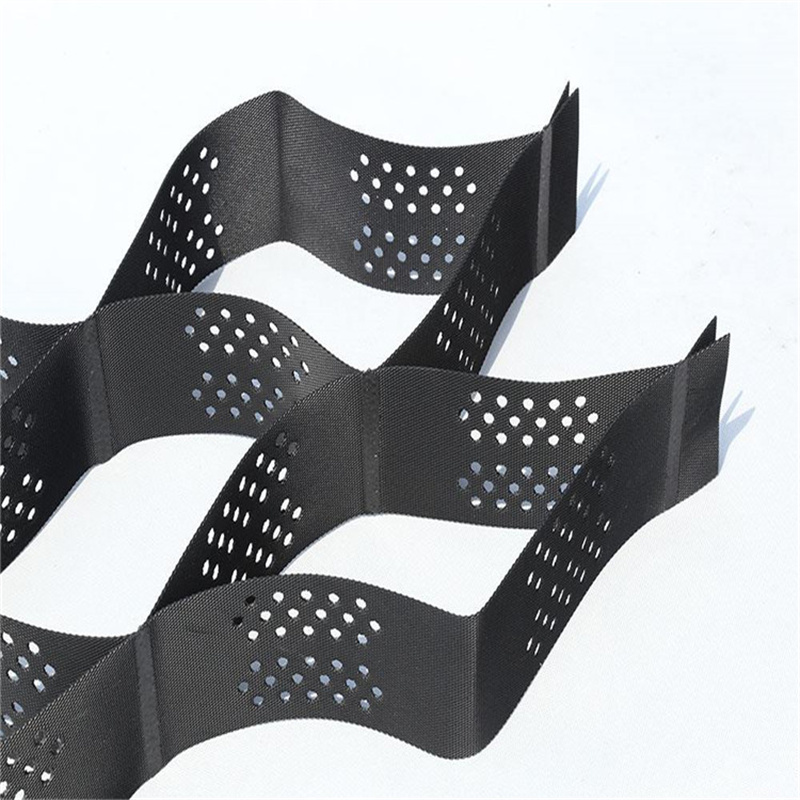

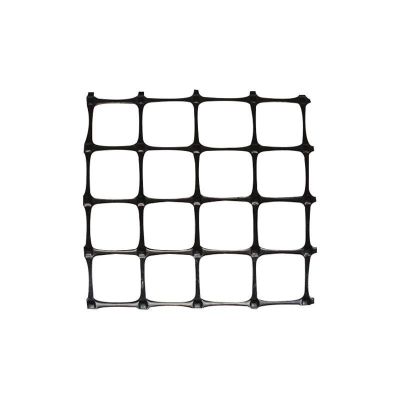

Geoglyph is a new type of environmentally friendly material. also known as honeycomb geoglyph. It is usually made of materials such as high-density polyethylene (HDPE) or polypropylene (PP). which has high strength and durability. The structure of the geoglery is usually a small mesh grid that can be superimposed and fixed to the ground to form a stable structure

If you're seeking a long-lasting, cost-effective, and high-performance solution for improving load-bearing capacity on unstable soils, Geocell for road reinforcement is the answer. Whether for highways, industrial access roads, or rural paths, this advanced geosynthetic solution delivers unmatched structural support, soil confinement, and erosion control — making it an essential material in today's demanding civil engineering projects.

What Is Geocell for Road Reinforcement?

Geocell for road reinforcement is a 3D cellular confinement system made from high-density polyethylene (HDPE) or polymer-based materials. These honeycomb-shaped cells expand on-site and are filled with granular materials like soil, sand, or gravel, creating a stable, load-distributing platform.

Once installed, Geocell for road reinforcement prevents lateral movement of the fill material, reduces rutting, and improves load distribution. This makes it ideal for sub-base stabilization, especially in weak soil conditions where traditional reinforcement methods often fail.

Why Choose Geocell for Road Reinforcement?

?️ Exceptional Load Distribution

Geocell for road reinforcement effectively spreads vertical loads over a wider area, significantly increasing the structural performance of pavements and reducing base layer thickness requirements.

? Works in All Soil Conditions

From soft clays to loose sands and high-moisture soils, Geocell for road reinforcement creates a mechanically stabilized layer that prevents settlement and surface deformation.

? Superior Erosion Control

Geocells offer slope stabilization and surface protection, particularly in areas prone to erosion, washout, or waterlogging — making them ideal for roadside shoulders and embankments.

? Quick and Cost-Effective Installation

Lightweight and easy to transport, geocells are simple to deploy and require less excavation, fewer materials, and shorter construction time — saving labor and budget.

Key Benefits of Using Geocell for Road Reinforcement

✔️ Increased pavement lifespan

✔️ Reduced base/sub-base thickness (up to 50%)

✔️ Compatible with local fill materials

✔️ Withstands heavy dynamic and static loads

✔️ Prevents rutting, cracking, and potholing

✔️ UV-resistant and weatherproof

✔️ Eco-friendly and recyclable

Applications of Geocell for Road Reinforcement

Geocell for road reinforcement is trusted in a wide range of construction and infrastructure projects:

? Highway and expressway construction

?️ Rural road and forest trail reinforcement

? Industrial and mining road stabilization

? Temporary construction access roads

?️ Airport runways and container yards

? Slope and embankment protection adjacent to roads

Real-World Testimonials

⭐⭐⭐⭐⭐

“We used geocell for road reinforcement on a mining haul road. The improvement was immediate — zero rutting even under constant heavy truck traffic.”

— Jonathan T., Site Manager

“After heavy rains, our old gravel road would always wash out. Since installing geocells for road reinforcement, it’s remained solid and usable year-round.”

— Angela M., Municipal Engineer

How Geocell for Road Reinforcement Outperforms Traditional Solutions

| Feature | Traditional Fill | Geocell Reinforcement |

|---|---|---|

| Load Distribution | Low | High |

| Soil Confinement | Weak | Strong |

| Material Cost Efficiency | Moderate | Excellent |

| Erosion Resistance | Poor | Exceptional |

| Installation Time | Long | Fast |

| Environmental Impact | High | Low |

Technical Specifications

? Cell Depth: 75mm–200mm

? Cell Size: 330mm–500mm (customizable)

? Tensile Strength: ≥ 20 kN/m

? Material: HDPE or PP with optional UV resistance

?️ Operating Temperature: -60°C to +60°C

?️ Seam Type: Ultrasonic welded for superior durability

Why Contractors and Engineers Trust Geocell for Road Reinforcement

✅ Proven in thousands of global road projects

✅ Reduced material and transportation costs

✅ Improved long-term road performance

✅ Strong ROI on public and private sector projects

✅ Certified to ISO/ASTM/CE/SGS standards

Advantages of Geocell

1. High performance: polymer HDPE technology; Secular creep; Softening and stress cracking; Coefficient of thermal expansion (CET).

2. Permeable moisture: geogge room with 98% open area. can collect rainwater; Reduce runoff; Use self-contained drainage decompression structure; Retain more water.

3. Soil conservation: geoglery can control the surface soil; Prevent erosion.

4. Soil fixation: geoglery can supplement the tensile strength of the soil and increase the shear strength of the soil; Micro-deformation of the basis of habit.

5. Change the Load Function: the geocell can withstand more than 10 times the cyclic load; Load stress reduction of more than 30%; Reduce the local and overall settlement of the foundation.

6. Erosion Resistance: accustomed to continuous or intermittent water flow; Vegetation. fillers. geomembrane and other multiple protection; The geocell can change the geometry of the channel.

Regulate water flow and elastic tissue to absorb the impact of water flow and surges.

What is Geocell?

Geocell is a three-dimensional, honeycomb-like cellular confinement system made from high-density polyethylene (HDPE) or polymeric materials. When expanded and filled with soil, gravel, or concrete, Geocells create a stable, reinforced structure that distributes loads and minimizes deformation — making them ideal for road base stabilization, erosion control, and load support.