0.5mm High Hdpe Geomembrane

Manufacturing Process

The manufacturing of 0.5mm high HDPE geomembrane follows a continuous extrusion and calendering process under strict quality control.

HDPE resin drying and gravimetric batching

High-temperature extrusion melting

Flat die or blown film sheet formation

Precision thickness calibration

Surface cooling and stress stabilization

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Key equipment includes twin-screw extruders, automatic thickness gauges, and infrared inspection systems.

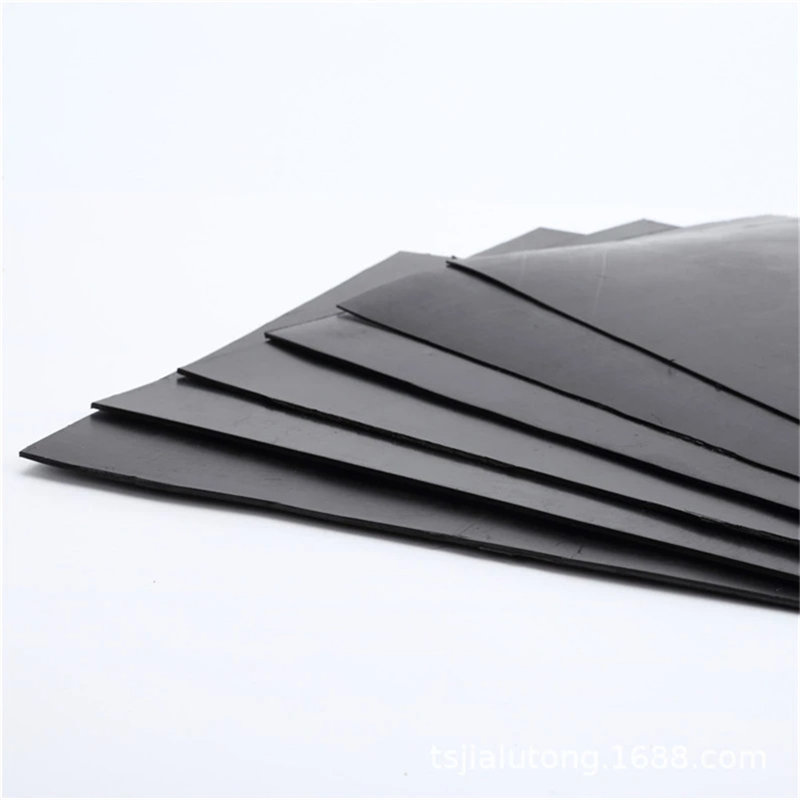

Product Definition

0.5mm High HDPE Geomembrane is a thin, flexible, impermeable geosynthetic liner manufactured from high-density polyethylene resin, designed for cost-effective containment, seepage control, and environmental protection in low to medium-risk engineering applications.

Technical Parameters and Specifications

The following parameters represent commonly accepted engineering ranges for 0.5mm high HDPE geomembrane used in civil and environmental projects.

Nominal thickness: 0.50 mm

Density: ≥0.94 g/cm³

Tensile strength at yield: ≥14 MPa

Elongation at break: ≥700%

Puncture resistance: ≥250 N

Carbon black content: 2.0–3.0%

Carbon black dispersion: Grade 1–2

Oxidative induction time (OIT): ≥100 min

Hydrostatic resistance: No leakage

Service temperature range: -40°C to +60°C

Structure and Material Composition

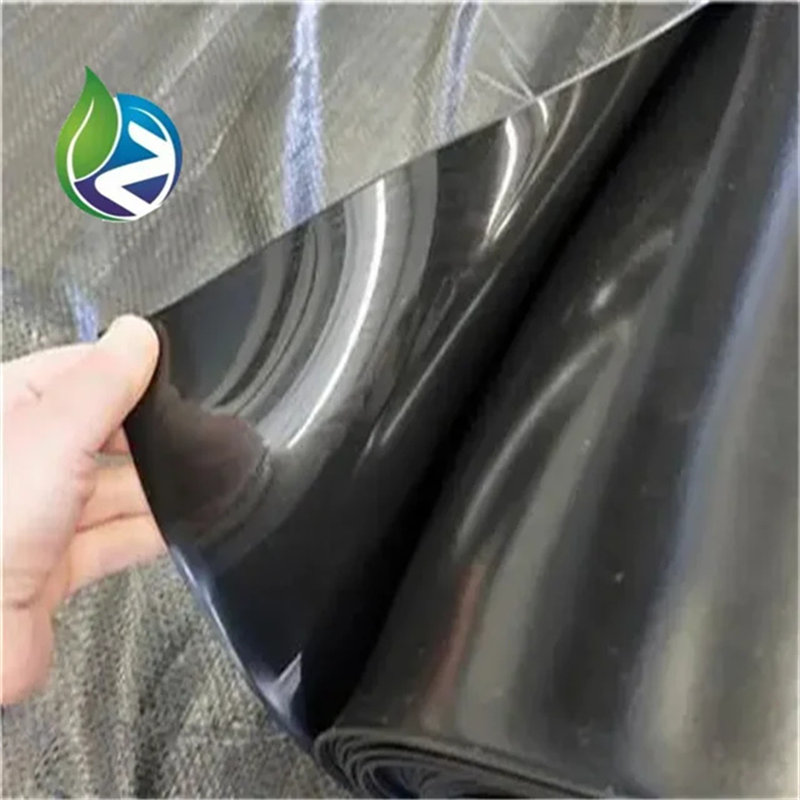

0.5mm high HDPE geomembrane adopts a homogeneous polymer structure optimized for flexibility and impermeability.

Base Polymer: Virgin high-density polyethylene (HDPE)

Stabilizer System: Carbon black for UV resistance

Antioxidants: Thermal and oxidative aging protection

Surface Type: Smooth (standard); optional textured on request

Manufacturing Process

The manufacturing of 0.5mm high HDPE geomembrane follows a continuous extrusion and calendering process under strict quality control.

HDPE resin drying and gravimetric batching

High-temperature extrusion melting

Flat die or blown film sheet formation

Precision thickness calibration

Surface cooling and stress stabilization

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Key equipment includes twin-screw extruders, automatic thickness gauges, and infrared inspection systems.

Industry Comparison

| Material | Impermeability | Mechanical Strength | UV Resistance | Cost Level |

|---|---|---|---|---|

| 0.5mm HDPE geomembrane | High | Medium | High | Low |

| 0.75mm HDPE geomembrane | Very High | High | High | Medium |

| LDPE geomembrane | Medium | Low | Medium | Low |

| PVC liner | Medium | Low | Low | Medium |

Application Scenarios

0.5mm high HDPE geomembrane is widely used by distributors, EPC contractors, and engineering firms in projects requiring economical lining solutions.

Irrigation canals and water reservoirs

Aquaculture ponds and shrimp farms

Temporary water storage facilities

Landscaping ponds and artificial lakes

Light-duty landfill cover systems

Biogas digesters (secondary containment)

Core Pain Points and Engineering Solutions

Budget constraints: 0.5mm thickness reduces material and transport costs

Installation efficiency: Lightweight rolls enable faster deployment

UV exposure risk: Carbon black stabilization improves outdoor durability

Leakage concerns: Heat-welded seams ensure continuous impermeability

Risk Warnings and Mitigation Recommendations

Despite its advantages, improper use of 0.5mm high HDPE geomembrane may introduce risks.

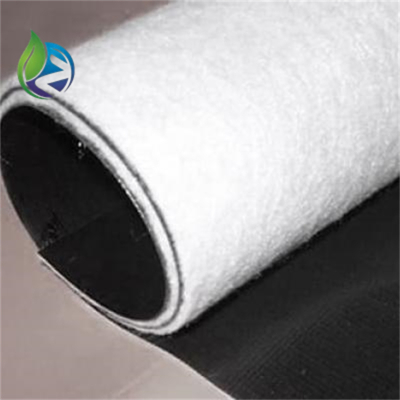

Risk of puncture on rough subgrade → require geotextile underlayment

Not suitable for high-head containment → evaluate thickness upgrade

Thermal expansion → allow slack during installation

Improper welding → conduct seam testing (air pressure or vacuum)

Procurement and Selection Guide

Confirm project containment risk level

Verify design head pressure and chemical exposure

Specify minimum resin and carbon black requirements

Request third-party test reports

Evaluate supplier production capacity and QC system

Assess logistics and roll dimensions

Plan installation and welding method in advance

Engineering Case Example

In a Southeast Asian aquaculture project, 0.5mm high HDPE geomembrane was installed over a 12,000 m² shrimp pond. With a nonwoven geotextile cushion layer and double-track hot wedge welding, the system achieved zero leakage after three operating seasons, while reducing liner costs by approximately 25% compared to thicker alternatives.

Frequently Asked Questions (FAQ)

Q1: Is 0.5mm HDPE suitable for landfill base liners?

A: Only for temporary or low-risk applications.Q2: Can it be exposed to sunlight?

A: Yes, with adequate carbon black content.Q3: What welding method is recommended?

A: Hot wedge welding.Q4: Does thickness tolerance matter?

A: Yes, uniform thickness ensures performance.Q5: Can it resist chemicals?

A: Suitable for mild acids and alkalis.Q6: Is textured surface necessary?

A: Only for slope stability requirements.Q7: What roll width is common?

A: 5–8 meters.Q8: How long is service life?

A: 10–20 years depending on exposure.Q9: Is third-party testing required?

A: Strongly recommended.Q10: Can it be repaired on site?

A: Yes, using extrusion welding patches.

Call to Action

For pricing, technical datasheets, or project-specific recommendations related to 0.5mm high HDPE geomembrane, please submit your application details to request a formal quotation, samples, or engineering support.

E-E-A-T Author Credentials

This article is authored by geosynthetics engineers with over a decade of experience in HDPE geomembrane manufacturing, quality control, and international civil engineering applications, supporting EPC contractors and importers across water, environmental, and infrastructure sectors.