Non Woven Geotextile

Nonwoven geotextiles are a vital component in the construction and civil engineering industry, offering a wide range of functionalities to improve the overall performance and durability of geotechnical structures.Their high tensile strength and durability allow them to reinforce soil and rock structures, improving their stability and resistance to deformation. They also provide effective drainage capabilities, allowing water to flow through while preventing soil particles from passing through, thus maintaining the integrity of the underlying soil or structure. In addition, nonwoven geotextiles serve as an effective barrier between different layers of soil or construction materials, preventing the mixing of incompatible materials and ensuring proper soil separation. They can also be used as a filter to prevent fine-grained soil particles from clogging drainage systems or entering waterways, protecting the environment from contamination.

Non Woven Geotextile: Reliable Soil Stabilization and Drainage Solution

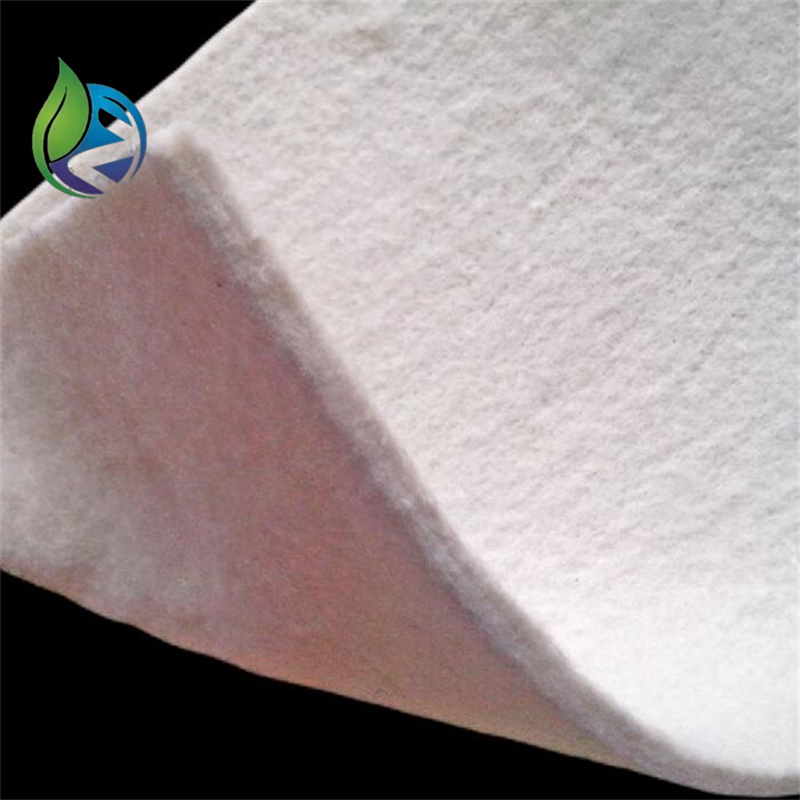

Non woven geotextile is a highly versatile geosynthetic fabric designed for a wide range of civil engineering, construction, and environmental applications. Known for its excellent filtration, separation, drainage, and protection capabilities, non woven geotextile is made by bonding fibers together through mechanical, thermal, or chemical means, rather than weaving. This results in a strong, durable, and permeable fabric ideal for stabilizing soil and controlling erosion.

What Is Non Woven Geotextile?

Non woven geotextile is produced using synthetic polymers such as polypropylene or polyester. These fibers are entangled or bonded into a flexible, felt-like sheet. Unlike woven geotextiles, which are made by weaving fibers, non woven geotextile offers greater permeability and is particularly effective in applications requiring drainage and filtration.

As a critical component in modern construction and geotechnical engineering, non woven geotextile enhances soil performance, prevents erosion, and extends the lifespan of infrastructure by reinforcing and separating materials beneath roads, railways, and embankments.

Key Features of Non Woven Geotextile

Excellent Water Permeability

One of the defining characteristics of non woven geotextile is its high permeability. It allows water to pass through while preventing soil particles from migrating, making it an ideal solution for drainage and filtration systems.Superior Filtration Performance

The unique structure of non woven geotextile ensures efficient filtration of fine particles, which prevents clogging in drainage layers and promotes long-term performance.Durability and UV Resistance

Manufactured from UV-stabilized polymers, non woven geotextile resists degradation from sunlight, chemicals, and biological agents, providing long-term reliability in outdoor environments.Flexible and Easy to Install

Lightweight and adaptable, non woven geotextile conforms to irregular surfaces and is easy to cut, transport, and install, saving time and labor on-site.High Tensile Strength and Elongation

Non woven geotextile offers a balance of strength and flexibility, ensuring that it can withstand significant ground movement without tearing or losing performance.

Applications of Non Woven Geotextile

Non woven geotextile is widely used across multiple industries due to its versatility and efficiency. Common applications include:

Road and Pavement Construction: Acts as a separation layer between subgrade and base materials to improve road durability.

Drainage Systems: Prevents soil clogging in subsurface drainage applications such as French drains and retaining walls.

Landfills and Environmental Protection: Used as a protective layer for geomembranes and to enhance leachate collection.

Erosion Control: Reinforces slopes, riverbanks, and shorelines, reducing soil loss from rainfall or water flow.

Retaining Wall Backfill: Prevents fines from entering drainage pipes while allowing water to escape.

In each of these cases, non woven geotextile contributes to system stability and long-term cost savings.

Installation Guidelines for Non Woven Geotextile

To ensure optimal performance, non woven geotextile should be installed with care:

Site Preparation: Remove debris, rocks, and vegetation before placement.

Unrolling: Lay the non woven geotextile flat over the prepared area without stretching or wrinkling.

Overlap: Ensure overlaps of at least 30 cm between adjacent sheets.

Anchoring: Use soil or mechanical fasteners to secure the geotextile in place.

Backfill: Place soil or aggregates over the geotextile as specified in the project plan.

Proper installation is crucial to the performance and longevity of non woven geotextile in any engineering application.

Advantages of Choosing Non Woven Geotextile

Effective Soil Separation and Reinforcement

Improved Drainage and Reduced Erosion

Enhanced Load Distribution in Roadbeds

Cost Savings in Construction and Maintenance

Sustainable and Environmentally Friendly

With proven performance in challenging environments, non woven geotextile is a dependable choice for engineers, contractors, and builders seeking efficient, long-lasting geotechnical solutions.

Conclusion

Non woven geotextile is a key element in modern civil and environmental engineering. Whether used in road construction, drainage systems, erosion control, or landfill protection, non woven geotextile delivers unmatched filtration, separation, and stability. As infrastructure demands continue to grow, investing in high-quality non woven geotextile ensures project success, longevity, and sustainability.