Geomembrane Liner Price

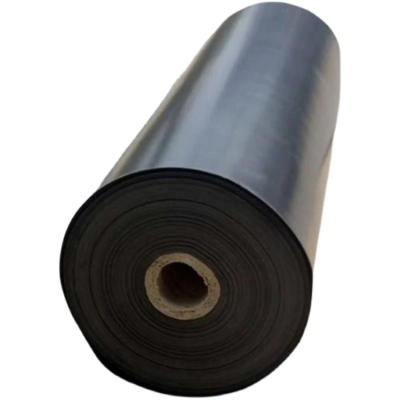

HDPE Membrane, additionally acknowledged as High Density Polyethylene Impermeable Membrane, is a top rate water-proof barrier cloth extensively utilized in a variety of engineering applications.

HDPE Membrane is diagnosed for its exquisite residences that make it an perfect desire for a multitude of seepage projects.It is a versatile and dependable water resistant barrier cloth that provides a aggregate of wonderful waterproofing, chemical resistance, mechanical strength, adaptability, and environmental friendliness. It's vast vary of purposes and highest quality overall performance make it an precious asset in the discipline of engineering and construction.

When it comes to long-lasting, reliable containment and sealing solutions, nothing performs better than a Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking. This advanced geomembrane material is widely used across industries such as environmental protection, mining, agriculture, and civil engineering—thanks to its unmatched durability, chemical resistance, and waterproofing capabilities.

In this article, we explore why Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking is the ultimate solution for demanding environments and how it outperforms traditional lining materials.

What Is a Waterproof Barrier Material HDPE Membrane?

A Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking is a high-density polyethylene liner engineered to act as a robust impermeable barrier. It is designed to prevent the migration of liquids, gases, and contaminants into the surrounding environment, making it ideal for applications such as:

Landfill lining and capping

Mining tailings and heap leach pads

Wastewater treatment ponds

Industrial lagoons

Agricultural water containment

Tunnel and dam waterproofing

The Key Strength: Environmental Stress Cracking Resistance

What sets this Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking apart is its ability to endure prolonged exposure to harsh stressors without failure.

Environmental Stress Cracking (ESC) is a common failure mode in plastics caused by the combined effects of stress and environmental conditions. Unlike conventional liners, this HDPE membrane resists microcracking even under high pressure, extreme temperatures, and chemical exposure.

This performance ensures long service life, minimized risk of leakage, and reduced maintenance or replacement costs over time.

Advantages of Using Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking

1. Superior Waterproofing Performance

As a waterproof barrier, this HDPE membrane provides a completely impermeable layer that blocks all forms of fluid seepage. It is particularly effective in preventing groundwater contamination in environmental protection projects.

2. High Tensile Strength and Flexibility

Despite its toughness, this membrane maintains flexibility, which makes it ideal for uneven terrains or dynamic loading environments. Its tensile strength also ensures it withstands heavy pressure and structural movement without damage.

3. Excellent UV and Chemical Resistance

Whether exposed to sunlight, acids, alkalis, or industrial chemicals, the Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking maintains its structural integrity and function.

4. Cost-Effective Over the Long Term

With fewer repairs, reduced downtime, and longer lifespan, the investment in high-quality HDPE membrane results in lower total lifecycle costs compared to other barrier materials like PVC or clay liners.

Technical Specifications (Typical)

| Property | Specification Range |

|---|---|

| Thickness | 0.5mm – 2.5mm |

| Tensile Strength at Yield | ≥ 16 MPa |

| Elongation at Break | ≥ 700% |

| Carbon Black Content | 2% – 3% |

| Stress Crack Resistance | ≥ 500 hours (ASTM D5397) |

| Water Vapor Transmission | ≤ 1.0 x 10⁻¹⁵ g·cm/(cm²·s·Pa) |

| UV Resistance | Excellent |

Specifications may vary based on regional standards or product customization.

Applications of HDPE Membrane with High ESC Resistance

Landfills: Acts as the primary liner in bottom and cap systems.

Mining Sites: Ensures safe containment of hazardous chemicals and leachates.

Aquaculture: Maintains water purity and prevents seepage.

Tunnels & Subways: Prevents groundwater infiltration.

Oil & Gas: Used as secondary containment and spill barriers.

Choosing the Right Waterproof Barrier HDPE Membrane Supplier

When selecting a Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking, it’s crucial to work with an experienced and certified supplier. Look for products tested under ASTM or GRI-GM13 standards, with proven performance in large-scale environmental and industrial applications.

Conclusion

A Waterproof Barrier Material HDPE Membrane with Excellent Resistance to Environmental Stress Cracking is more than just a liner—it’s a long-term investment in environmental safety, industrial efficiency, and structural reliability. Its high resistance to stress cracking, combined with outstanding waterproofing and chemical durability, makes it the industry benchmark for modern containment systems.

Whether you're managing a landfill, mining operation, or large-scale irrigation project, choosing this high-performance HDPE membrane ensures peace of mind, regulatory compliance, and enduring performance.