Mine Re-greening Project: Geotextiles Achieve a Win-Win Situation for Ecology and Safety

Mine Revegetation Projects: Geotextiles Achieve a Win-Win for Ecology and Safety

In recent decades, the global push for sustainable development has pushed mine rehabilitation right to the top of environmental and industrial agendas. Abandoned mines, once symbols of resource extraction and economic growth, usually leave behind broken ecosystems—eroded soil, bare ground, water sources choked with sediment. These issues aren’t just bad for nature. They pose long-term risks to nearby communities too. Industries and governments have been scrambling for solutions that fix both problems at once. Geotextiles have stepped up as a game-changing material here. They blend ecological restoration and safety enhancement in a way few other products can. The real magic? They tackle two huge priorities head on: bringing damaged land back to life, making mine sites safe from hidden hazards. This piece takes a look at how geotextiles are changing mine revegetation for good—benefits way beyond just slapping grass on bare dirt.

The Dual Crisis of Abandoned Mines: Ecology and Safety

Abandoned mine sites come with a double whammy that needs a full-on fix. Ecologically, these places are a mess. Soil erodes fast without plants holding it in place. Rain washes topsoil into rivers and streams, messing up fish habitats and drinking water. No plants mean no natural carbon capture either. Local air quality drops, microclimates shift in weird, unpredictable ways. On the safety side, unstable slopes and tailings piles are ticking time bombs. Heavy rain, even a small earthquake, can trigger landslides or tailings dam failures. That puts nearby homes, roads, even people’s lives in danger.

Old-school rehab methods? They just don’t cut it. Manual soil replacement’s expensive, takes ages, and it never sticks around for the long haul, honestly. Concrete stabilization stops erosion, sure—but it creates a dead zone where nothing grows. The industry needs something that hits both ecological and safety boxes. That’s where geotextiles come in. Geotextile waterproofing is the key piece bridging stability and sustainability here. It creates a barrier that controls water flow but still lets soil breathe. That’s the foundation for both safe slopes and plants that can actually grow, survive. No fancy workarounds needed—just a simple, effective layer that pulls double duty.

Geotextiles in Ecological Restoration: Building a Foundation for Green Growth

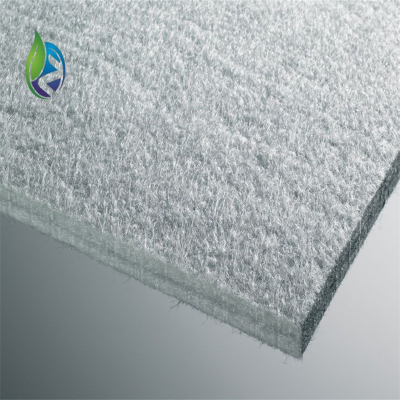

Mine revegetation only works if you make a place where plants can root and thrive. Geotextiles are perfect for this. They act as a protective layer fixing the two biggest issues: eroding soil and lost nutrients. Lay ’em on mine slopes, and these permeable fabrics stop rain from washing away the topsoil. But they still let water and air seep down to the dirt underneath. That balance is make-or-break for seeds sprouting and roots spreading—plants need both moisture and oxygen to grow, after all. Can’t skip that basic fact, no matter how advanced the tech gets.

Geotextiles help hold onto soil nutrients too—nutrients almost always in short supply at abandoned mines. They slow down water runoff, giving nutrients time to soak into the soil instead of getting carried away. Some geotextiles even work like mulch. Keep soil temperatures steady, cut down on evaporation—super important in dry areas where water’s hard to come by. As revegetation moves forward, the geotextile layer either breaks down slowly (if it’s eco-friendly) or stays put as a long-term barrier. Depends entirely on the project’s needs, really. A big part of this process is geotextile waterproofing. It stops too much water pooling in the soil and causing root rot. But it also directs water to where plants need it most—right at the root zone. This targeted water management doesn’t just help plants grow. It helps fix the soil’s natural water cycle too—a must for full ecological recovery. Can’t have one without the other, plain and simple.

Geotextiles in Safety Enhancement: Fortifying Mine Sites Against Hazards

Ecological restoration is the main goal of mine revegetation, but safety can’t be an afterthought. Unstable slopes and tailings piles are some of the biggest risks at abandoned mines. Geotextiles play a huge role in lowering those risks. Their structural strength helps reinforce soil. Spread weight evenly across slopes, cut down on landslide chances. Pair them with other stabilization tricks—rock bolting, soil nailing—and geotextiles make a tough barrier that handles crazy weather. Heavy monsoons, freezing winters, sudden heatwaves. They hold up when other materials fail, no question.

Tailings management is another area where geotextiles shine. Mine tailings—the leftover gunk from ore processing—are usually piled up or stored in dams. Don’t contain them right, and they leak toxic chemicals into the environment. Geotextiles act as a filter layer. Stop fine tailings particles from washing away but still let water drain. That not only cuts contamination risks, it stabilizes the tailings pile too, making it less likely to collapse. In these jobs,geotextile waterproofing is non-negotiable—can’t skip it for a second. It creates a tight barrier stopping harmful stuff seeping into groundwater or nearby waterways. Mix filtration and waterproofing, geotextiles make tailings management safe and eco-friendly. Protects both people’s health and the ecosystem around the mine. No more choosing one or the other—this is the balance the industry’s been after for years.

Technical Considerations for Geotextile Application in Mine Revegetation

To get the most out of geotextiles in mine revegetation, you’ve got to zero in on two things: picking the right material, installing it correctly. Not all geotextiles are the same. The one you choose depends on the mine site’s specific conditions—soil type, how steep the slopes are, climate, what kind of plants you’re planting. Woven geotextiles, for example, are great for jobs needing high tensile strength, like slope stabilization. Non-woven ones are better for filtration and holding soil in place. It’s basic matching—right tool for the right job. Field crews figure this out the hard way—mess it up, and you’re stuck redoing the whole job. Total waste—time, money, all of it.

Installation matters just as much as material choice. Geotextiles have to be laid right to work properly. That means overlapping edges so soil can’t slip through gaps. Securing the fabric to the ground with anchors or staples. Prepping the surface before you even lay the first piece—no loose rocks, no sharp bits of debris that’ll rip the fabric to shreds. A single sharp stone under the fabric? Heavy rain hits, and the whole setup’s ruined. Install geotextiles wrong, and they fail early. Messes up both ecological restoration and safety measures. A key technical detail you can’t skip is geotextile waterproofing. It needs precise installation to keep the waterproof layer continuous, no holes. Even a small gap or tear lets water seep through. Weakens slopes, breaks tailings containment. Work with pros who know the ins and outs of geotextile installation—only way to get the results you want. Experience always beats guesswork, every time.

Industry Trends and the Future of Geotextiles in Mine Revegetation

As demand for sustainable mine rehab grows, the geotextile industry’s changing to keep up. One of the most exciting trends is eco-friendly geotextiles made from renewable materials. Jute, coir, biodegradable polymers—stuff like that. These materials work just as well as traditional synthetic ones but leave a way smaller environmental footprint. Perfect for projects that care about full, natural ecological restoration—no leftover plastic, no long-term pollution. More and more sites are switching to these options, and the quality’s only getting better as time goes on.

Another big trend is smart geotextiles. These have sensors embedded in them monitoring soil moisture, temperature, slope stability in real time. The data they collect lets project managers make better decisions about watering, maintenance, hazard control. No more guessing when to water or if a slope is stable—you’ve got the numbers right at your fingertips. As these smart technologies become more common, geotextile waterproofing is getting upgrades too. New materials, new designs offering better durability, better performance in extreme conditions. Self-healing waterproofing geotextiles, for example—they can fix small tears or gaps on their own. Cuts down on manual maintenance, makes the geotextile layer last longer. Small tweaks like that? They make a big difference over time, you know.

Conclusion

Mine revegetation is a tricky, multi-layered challenge. It needs solutions that fix both ecological damage and safety risks. Geotextiles have become a versatile, effective tool for this. They deliver that win-win: bringing broken ecosystems back to life, making mine sites safe from hazards. Holding soil in place, keeping nutrients around, stabilizing slopes, containing tailings—geotextiles play a critical role in every step of mine rehab. Geotextile waterproofing runs through all these key uses. Makes sure water’s managed right—supports plant growth, keeps structures stable at the same time. Not the flashiest part of the process, by any means—but it’s the one that makes everything else click.

As the industry keeps innovating—eco-friendly materials, smart tech leading the way—geotextiles will only get more important for mine revegetation. With these solutions, industries and governments can not only turn abandoned mine sites back into natural areas. They can keep nearby communities safe for years to come. The success of geotextiles in mine revegetation isn’t some big, flashy statement about sustainable engineering. It’s just proof that you can balance industrial development with protecting the environment and people. In the end, this win-win isn’t just a project outcome. It’s a model for sustainable development that works in other industries, other environmental problems around the world. No grand promises, just real results from a material that does exactly what it’s supposed to do—and does it well.