High Quality Short Fiber Geotextile

Manufacturing Process

High quality short fiber geotextile is produced through a fully controlled industrial process to ensure consistency and performance reliability.

Selection and opening of PET or PP staple fibers

Carding and web formation for uniform fiber distribution

Layer stacking to achieve target mass per unit area

Needle punching for mechanical bonding and strength

Heat setting to stabilize dimensions (optional)

Online inspection of thickness, weight, and defects

Roll cutting, labeling, and protective packaging

Key equipment includes fiber openers, carding machines, needle-punch looms, thickness gauges, and tensile testing systems.

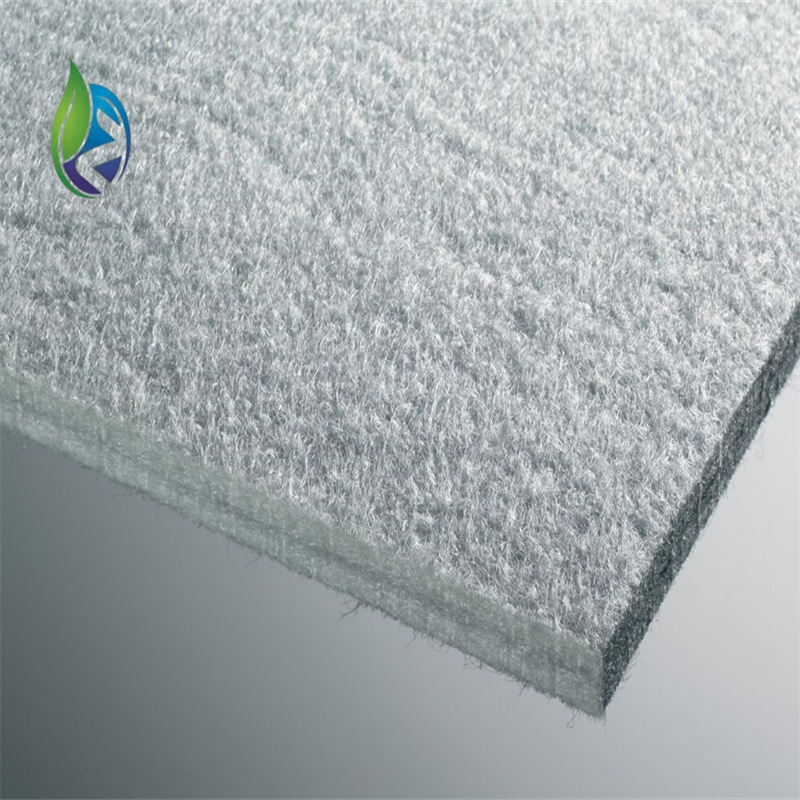

Product Definition: What Is High Quality Short Fiber Geotextile?

High quality short fiber geotextile is a nonwoven geosynthetic material manufactured from polyester (PET) or polypropylene (PP) staple fibers through needle punching. It is engineered for separation, filtration, drainage, and reinforcement functions in civil, environmental, and infrastructure projects.

Technical Parameters and Specifications

High quality short fiber geotextile performance is defined by standardized mechanical and hydraulic indicators suitable for long-term engineering applications.

Raw Material: PET or PP short (staple) fiber

Manufacturing Method: Needle-punched nonwoven

Mass per Unit Area: 100–800 g/m²

Tensile Strength: 6–35 kN/m

Elongation at Break: 40%–80%

CBR Puncture Strength: 1.0–6.5 kN

Water Permeability (Vertical): ≥ 10⁻² m/s

Equivalent Opening Size (O90): 0.07–0.30 mm

Thickness (2 kPa): 0.9–6.0 mm

UV Resistance Retention (500 h): ≥ 70%

Applicable Standards: ASTM D4595, EN ISO 10319, ASTM D6241

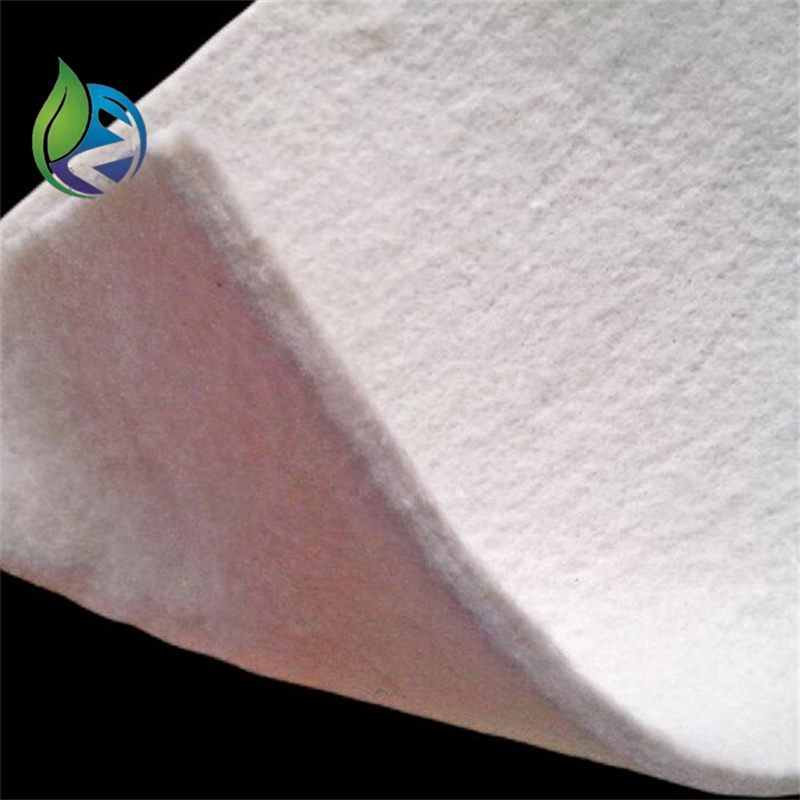

Structure and Material Composition

The internal structure of high quality short fiber geotextile determines its multi-functional engineering performance.

Staple Fiber Matrix: Randomly oriented PET or PP fibers

Needle-Punched Network: Mechanical entanglement ensuring isotropic strength

Porous Structure: Enables controlled water flow and soil retention

Surface Uniformity: Improves contact with soil and aggregates

Chemical Stability: Resistant to acids, alkalis, and biological degradation

Manufacturing Process

High quality short fiber geotextile is produced through a fully controlled industrial process to ensure consistency and performance reliability.

Selection and opening of PET or PP staple fibers

Carding and web formation for uniform fiber distribution

Layer stacking to achieve target mass per unit area

Needle punching for mechanical bonding and strength

Heat setting to stabilize dimensions (optional)

Online inspection of thickness, weight, and defects

Roll cutting, labeling, and protective packaging

Key equipment includes fiber openers, carding machines, needle-punch looms, thickness gauges, and tensile testing systems.

Industry Comparison: Short Fiber vs Other Geotextiles

| Parameter | Short Fiber Geotextile | Filament Geotextile | Woven Geotextile | Geogrid |

|---|---|---|---|---|

| Manufacturing Type | Nonwoven, needle-punched | Nonwoven, spunbond | Woven | Extruded / Welded |

| Filtration Performance | Excellent | Good | Limited | Not applicable |

| Isotropic Strength | Yes | Yes | No | Directional |

| Drainage Capability | High | Moderate | Low | None |

| Cost Efficiency | High | Moderate | Moderate | Higher |

Application Scenarios

High quality short fiber geotextile is widely used by EPC contractors, distributors, and engineering firms across infrastructure sectors.

Road and highway subgrade separation

Railway ballast stabilization

Landfill drainage and protection layers

Riverbank and coastal erosion control

Tunnel and underground drainage systems

Retaining wall and slope protection projects

Core Engineering Pain Points and Solutions

Soil Contamination: Prevents intermixing of subgrade and aggregate layers

Poor Drainage: Maintains permeability while retaining soil particles

Uneven Settlement: Distributes loads and improves subgrade stability

Material Degradation: PET/PP fibers ensure long-term chemical resistance

Risk Warnings and Mitigation Recommendations

Ensure correct orientation and overlap during installation

Avoid prolonged UV exposure before backfilling

Match opening size to soil gradation to prevent clogging

Use protective layers to avoid puncture during construction

Procurement and Selection Guide

Identify project function: separation, filtration, drainage, or protection

Define required tensile strength and puncture resistance

Select appropriate mass per unit area

Verify compliance with project specifications and standards

Review third-party laboratory test reports

Evaluate supplier production capacity and QA systems

Confirm roll dimensions, logistics, and technical support

Engineering Case Study

In a highway expansion project, a 300 g/m² high quality short fiber geotextile was installed between the soft clay subgrade and crushed stone base. Post-construction monitoring showed improved drainage performance and reduced rutting, extending pavement service life and reducing maintenance costs.

Frequently Asked Questions (FAQ)

What is high quality short fiber geotextile used for? – Separation, filtration, drainage, and protection

Is short fiber geotextile suitable for soft soils? – Yes

What is the difference between short fiber and filament geotextile? – Fiber length and structure

Can it be used in drainage systems? – Yes

Is PET or PP better? – Depends on chemical and temperature conditions

How long does it last underground? – Typically over 50 years

Does it resist biological degradation? – Yes

Can it be combined with geomembranes? – Commonly used together

Does it require special installation tools? – No

Is third-party testing recommended? – Strongly recommended

CTA – Request Quotation or Technical Documentation

Procurement managers, EPC contractors, and distributors may request technical datasheets, compliance certificates, pricing, or engineering samples for tender preparation and design verification.

E-E-A-T Author Credentials

This article is prepared by geosynthetics engineering professionals with extensive experience in infrastructure design, material testing, and international project delivery. All technical parameters are aligned with recognized ASTM and EN standards and proven field applications.