Waterproo Woven Geotexitle

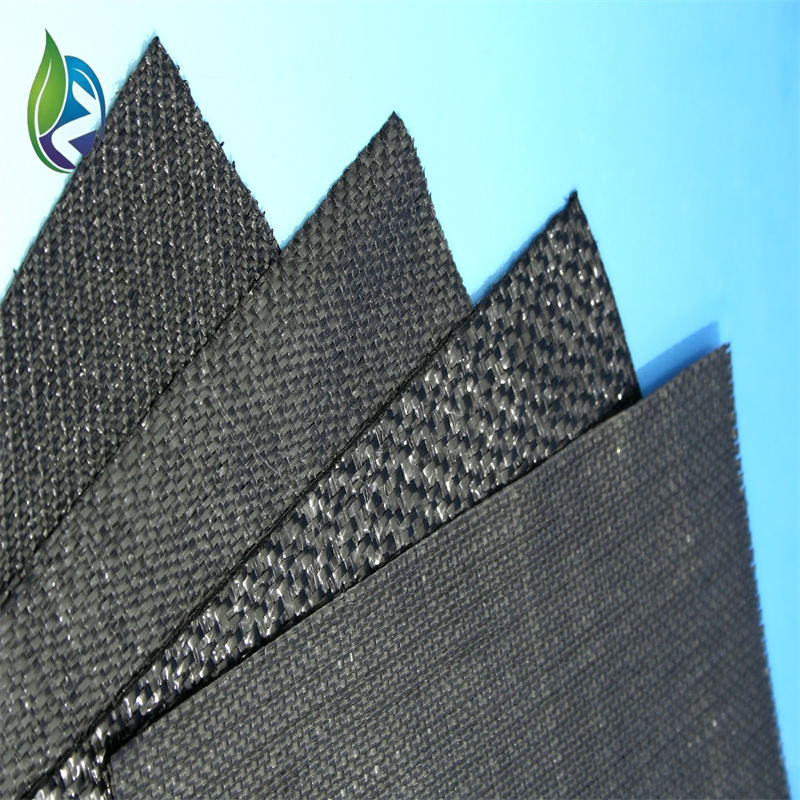

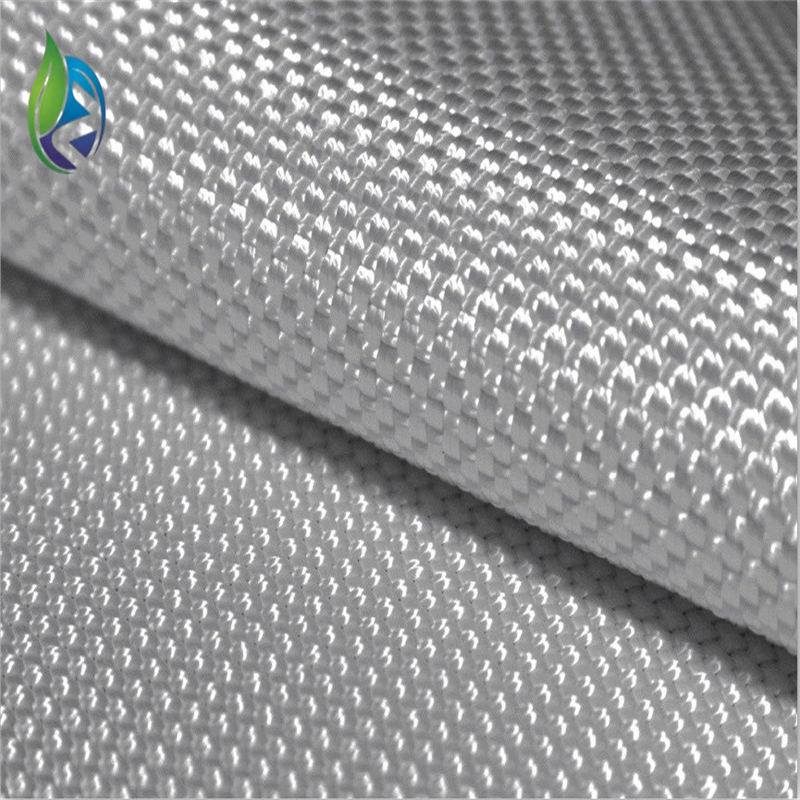

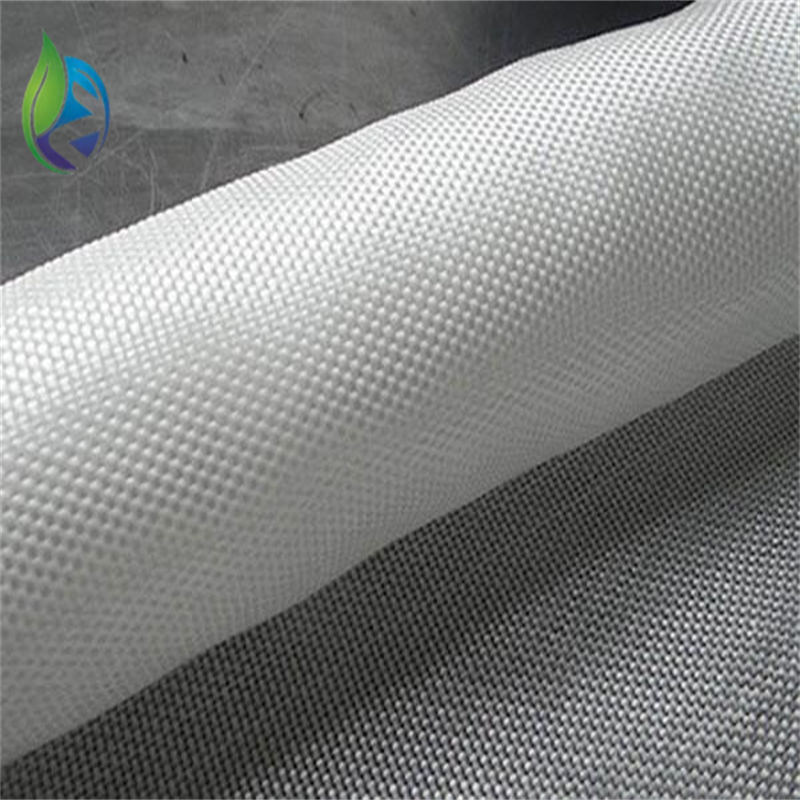

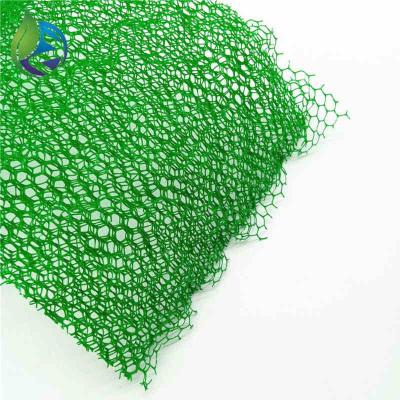

Woven geotextile is a versatile and robust geosynthetic material crafted from high-performance fibers such as polypropylene or polyester. It is produced through intricate weaving techniques, resulting in a durable fabric with a defined grid pattern of interlocking yarns that run both lengthwise and widthwise. This intricate structure offers exceptional strength, durability, and resistance to wear, making it ideal for a wide range of civil engineering applications. Woven geotextiles exhibit excellent water permeability, allowing for controlled drainage while maintaining soil stability. Additionally, they are resistant to chemical degradation, UV radiation, and biological attack, ensuring long-term performance. Commonly used in road construction, erosion control, water retention systems, and environmental remediation projects, woven geotextiles offer a cost-effective and environmentally friendly solution for reinforcing, separating, and protecting soil structures.

Woven Geotextile for Reinforcement and Waterproofing

Woven geotextile for reinforcement and waterproofing is a high-performance geosynthetic material engineered to provide structural strength, soil stabilization, and moisture resistance in a variety of civil and environmental engineering projects. Manufactured by weaving polypropylene or polyester yarns in a precise pattern, woven geotextile for reinforcement and waterproofing combines superior tensile strength with excellent filtration and separation capabilities.

What Is Woven Geotextile for Reinforcement and Waterproofing?

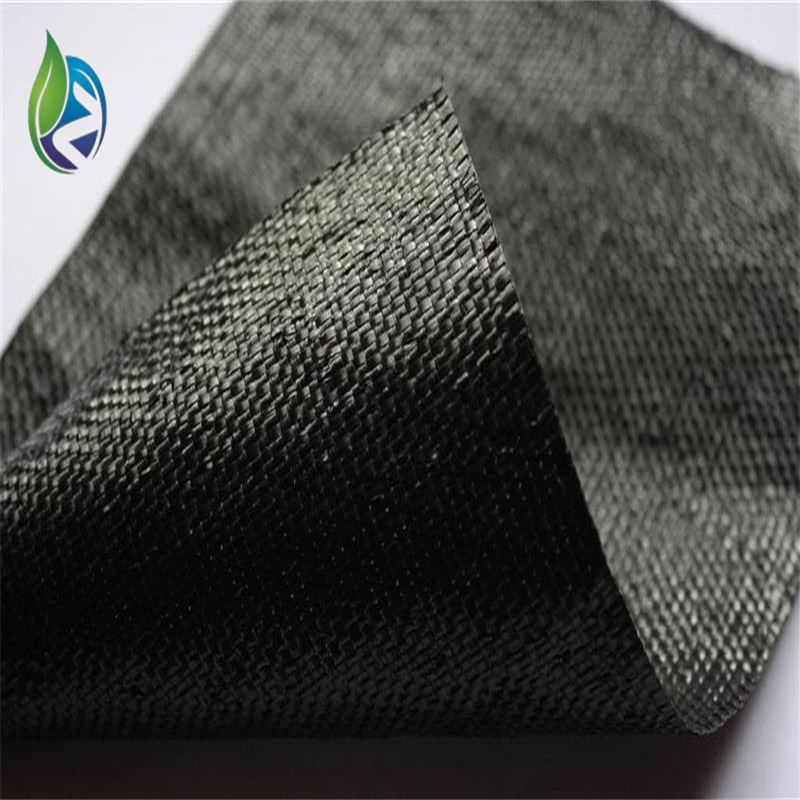

Woven geotextile for reinforcement and waterproofing is created through an interlacing process of two sets of synthetic fibers—warp and weft—resulting in a durable fabric with low elongation and high load-bearing capacity. This fabric is widely used in applications where soil reinforcement and water control are critical, such as roads, embankments, retaining walls, and drainage systems.

Unlike non-woven fabrics, woven geotextile for reinforcement and waterproofing offers improved structural integrity and long-term stability, making it the preferred choice in projects requiring heavy-duty performance and effective waterproofing solutions.

Key Features of Woven Geotextile for Reinforcement and Waterproofing

High Tensile Strength

Designed for demanding environments, woven geotextile for reinforcement and waterproofing provides outstanding tensile strength, making it ideal for soil reinforcement and load distribution.Excellent Waterproofing Support

While the fabric itself is not a membrane, woven geotextile for reinforcement and waterproofing works synergistically with geomembranes or waterproof coatings to create effective water barriers in construction.Superior Filtration and Separation

The woven structure allows water to pass through while preventing the movement of soil particles, maintaining drainage function and preventing erosion.Dimensional Stability

With minimal elongation under stress, woven geotextile for reinforcement and waterproofing ensures stable performance over time, even under heavy loads and environmental stress.Chemical and UV Resistance

Resistant to degradation from chemicals, acids, alkalis, and UV rays, woven geotextile for reinforcement and waterproofing is suitable for both buried and exposed applications.

Applications of Woven Geotextile for Reinforcement and Waterproofing

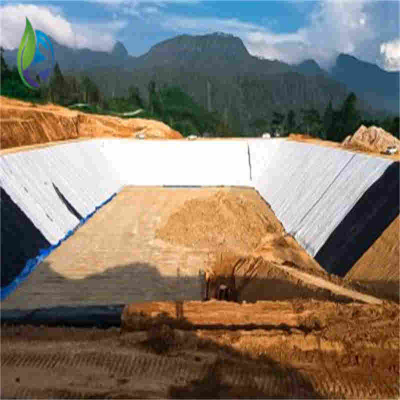

Woven geotextile for reinforcement and waterproofing is used across a wide range of civil, environmental, and infrastructure projects:

Road and Highway Construction

It strengthens weak subgrades, prevents mixing of soil layers, and enhances road longevity by improving load distribution.Slope and Embankment Reinforcement

Woven geotextile for reinforcement and waterproofing stabilizes slopes and embankments, reducing the risk of landslides and soil erosion.Retaining Wall Backfill

It maintains structural integrity by reinforcing the soil behind retaining walls and supporting effective drainage.Waterproofing Systems

Often used in conjunction with geomembranes in landfill liners, tunnels, or reservoir systems, it enhances waterproofing while providing additional support.Railway Ballast Stabilization

Placed under ballast layers to improve stability, reduce maintenance, and extend the life of railway tracks.

In all of these applications, woven geotextile for reinforcement and waterproofing plays a critical role in improving ground performance and moisture management.

Installation Guidelines

For best performance, follow these general steps when installing woven geotextile for reinforcement and waterproofing:

Prepare the Subgrade

Remove all debris, large stones, and vegetation to create a clean, even surface.Roll Out the Fabric

Lay the woven geotextile for reinforcement and waterproofing with minimal wrinkles and overlaps of 30–45 cm between adjacent panels.Anchor and Secure

Use staples, pins, or soil anchoring methods to fix the geotextile in place.Apply Overlay Materials

Place gravel, sand, or geomembranes on top, depending on the project requirement, ensuring consistent coverage.Compaction

Compact the fill material properly to maximize performance and longevity.

Advantages of Woven Geotextile for Reinforcement and Waterproofing

Enhances soil load-bearing capacity

Reduces soil movement and erosion

Supports long-term waterproofing performance

Compatible with a wide range of materials

Cost-effective and easy to install

By choosing woven geotextile for reinforcement and waterproofing, engineers and contractors can ensure durability, safety, and efficiency in infrastructure development.

Conclusion

Woven geotextile for reinforcement and waterproofing is a reliable and essential material in modern construction and geotechnical engineering. Its ability to reinforce weak soils, improve drainage, and support waterproofing systems makes it a top choice for sustainable and resilient infrastructure. Whether you're building highways, stabilizing slopes, or protecting against moisture intrusion, woven geotextile for reinforcement and waterproofing offers the strength and performance you need.