Containment Biogas Digester Geomembrane

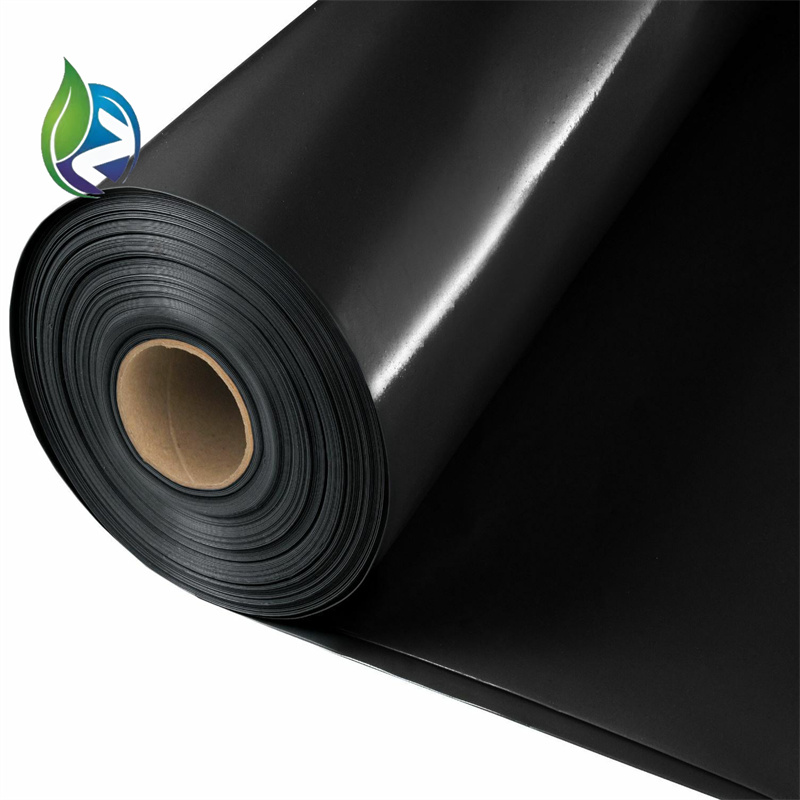

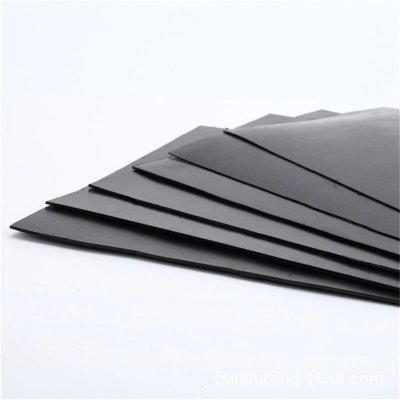

Zhuyuan containment biogas digester geomembranes are typically made from high-quality materials such as HDPE (High-Density Polyethylene) or LLDPE (Linear Low-Density Polyethylene) to ensure durability and longevity in biogas applications. These geomembranes are available in various thicknesses and sizes to accommodate different digester designs and volumes. The installation of the geomembrane is crucial in maintaining the integrity of the biogas digester system, as it provides a secure barrier against gas leaks and environmental contamination. Proper maintenance and inspection of the geomembrane are essential to ensure optimal performance and safety of the biogas digester.

Product Details

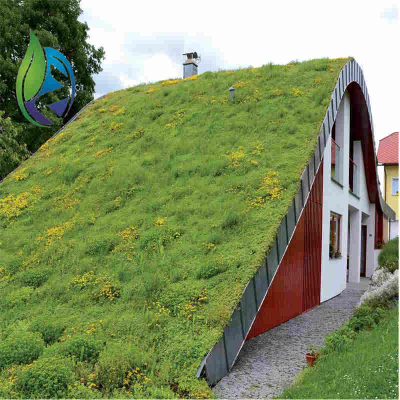

As global energy needs evolve and sustainability becomes a priority, biogas technology has rapidly grown in popularity. At the heart of every efficient anaerobic digester lies a critical yet often overlooked component: the containment biogas digester geomembrane. Whether you’re planning a rural waste-to-energy project or an industrial-scale bioenergy facility, choosing the right containment geomembrane can make or break system efficiency and lifespan.

This comprehensive guide will walk you through what a containment biogas digester geomembrane is, why it matters, how to select the best one, and what real users are saying.

? What Is a Containment Biogas Digester Geomembrane?

A containment biogas digester geomembrane is a specially engineered synthetic liner designed to prevent leaks, retain gas, and isolate waste in anaerobic digestion systems. Typically made from HDPE (High-Density Polyethylene), LLDPE, or PVC, these geomembranes form a gas-tight, chemical-resistant, and UV-stable barrier between the biogas slurry and the environment.

?️ Its main roles? Prevent leakage, retain methane-rich gas, and ensure structural stability for years, even under intense chemical and microbial activity.

? Why the Right Containment Geomembrane Matters

✅ Gas Retention Efficiency

The geomembrane acts as a gas seal—preventing precious methane from escaping, which boosts overall biogas output and project ROI.

✅ Leakage Prevention

A failed containment system can pollute groundwater and cause financial losses. A high-quality biogas digester geomembrane eliminates this risk.

✅ UV & Chemical Resistance

Outdoor digesters are exposed to intense sunlight and corrosive organic acids. A premium geomembrane resists both.

✅ Longevity & Low Maintenance

Most containment geomembranes offer 15–25 years of performance with minimal upkeep.

✅ Customizable Thickness & Welding

Engineers can choose 1.0mm, 1.5mm, or even 2.0mm thickness depending on tank size and pressure, and field welding ensures seamless application.

?️ Common Applications of Biogas Containment Geomembranes

✅ Rural livestock biogas digesters

✅ Industrial food/agro-waste digestion tanks

✅ Municipal sludge treatment plants

✅ Floating biogas dome covers

✅ Slurry storage ponds with gas recovery systems

? What to Look for in a High-Quality Biogas Digester Geomembrane

When sourcing a containment biogas digester geomembrane, ensure it meets these standards:

| Parameter | Recommendation |

|---|---|

| Material | HDPE or LLDPE with UV stabilization |

| Thickness | 1.5mm standard (can vary by design) |

| Tensile Strength | ≥ 25 MPa |

| Puncture Resistance | High (important for gravel/rock subgrades) |

| Welding Compatibility | Hot wedge or extrusion welding support |

| Gas Permeability | Near zero |

| Certifications | ISO 9001, CE, ASTM, GRI-GM13 compliant |

? Installation Tips for Containment Geomembranes

Always install on a smooth, compacted subgrade

Use geotextile underlayers for rocky soil conditions

Field-weld seams with proper overlap and pressure testing

Regularly inspect for tension, anchoring, and gas venting points

? Real User Reviews

@GreenFarmBiogas

“We installed a 1.5mm HDPE containment biogas digester geomembrane 3 years ago. Still gas-tight, no leaks, and output has even improved thanks to better retention.”

@EcoWasteTech

“Switched from clay-based containment to HDPE geomembrane—biggest upgrade we ever made. Easy to install, and we got customized rolls pre-welded.”

@AfricaBioProject

“Tough enough to handle our intense UV and high ammonia content. The geomembrane hasn’t failed once and is still holding shape perfectly.”

? Sustainability Advantage

Using a containment biogas digester geomembrane not only improves system efficiency but also supports global sustainability goals:

Reduces methane emissions into the atmosphere

Prevents groundwater contamination

Supports clean energy production from organic waste

Increases resource recovery in developing regions

? Custom Sourcing Options

Many suppliers offer tailored containment biogas digester geomembrane solutions including:

Roll widths up to 7m for fewer seams

Anti-slip surface textures for tank interiors

Geomembrane + geotextile systems

Installation guidance or on-site services

Bulk export packaging with container load optimization

? Final Thoughts

Choosing the right containment biogas digester geomembrane is more than just a technical decision—it’s a commitment to performance, safety, and sustainability. With rising energy prices and growing environmental concerns, this essential component is key to maximizing your biogas project's long-term value.

1. Biogas Plants: Geomembranes are commonly used in biogas plants to contain and store the produced biogas, ensuring efficient gas collection and management.

2. Landfills: Geomembranes are utilized in landfills to prevent gas emissions and leachate contamination, promoting environmental protection and waste management.

3. Wastewater Treatment Plants: Geomembranes play a crucial role in wastewater treatment plants by containing gases generated during the treatment process, enhancing operational efficiency.

4. Agricultural Biogas Systems: Geomembranes are employed in agricultural biogas systems to capture and store biogas produced from organic waste, supporting sustainable energy production.

5. Industrial Applications: Geomembranes find applications in various industrial settings for gas containment, environmental protection, and waste management purposes.

Containment biogas digester geomembranes play a vital role in various applications such as biogas plants, landfills, wastewater treatment plants, agricultural biogas systems, and industrial settings. These geomembranes are designed for easy installation, offer seam integrity to prevent leaks, exhibit temperature and UV resistance, and are cost-effective in the long run. By effectively containing gases and liquids, geomembranes contribute to environmental protection, waste management, and sustainable energy production across different sectors. Their versatility and reliability make them indispensable in ensuring efficient gas collection, storage, and management in diverse industrial and agricultural processes.

Leave your messages