HDPE Geocell

1.Light material, wear resistance.

2.Chemical stability, light oxygen aging resistance, acid and alkali resistance.

3.Anti-deformation, effectively enhance the subgrade bearing capacity.

4.Transport volume is small, flexible.

When it comes to modern infrastructure and ground reinforcement, HDPE Geocell technology is transforming how we build—both above and below the surface. Whether you’re stabilizing a highway shoulder, reinforcing a slope, or building a green retaining wall, HDPE geocells offer strength, flexibility, and eco-efficiency in one compact system.

But what exactly is an HDPE geocell, and why are civil engineers worldwide making it their go-to soil reinforcement solution?

Let’s break it down.

What is an HDPE Geocell?

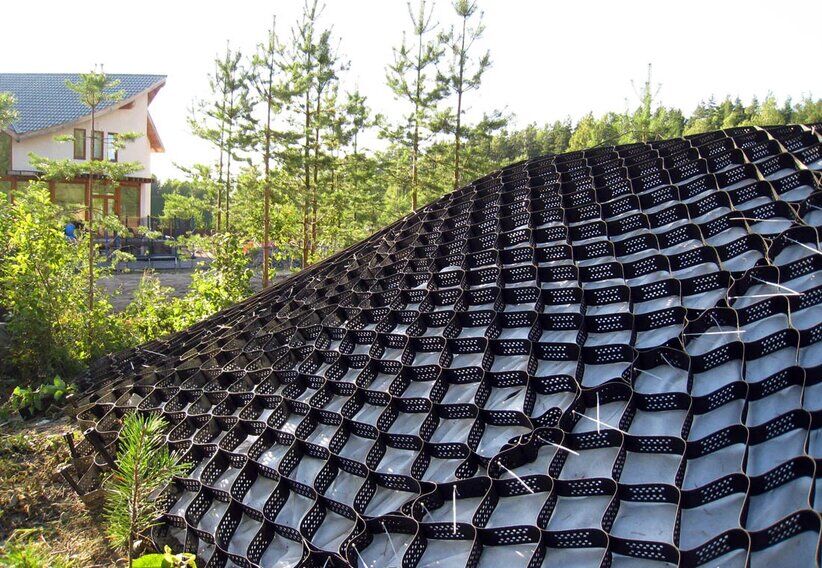

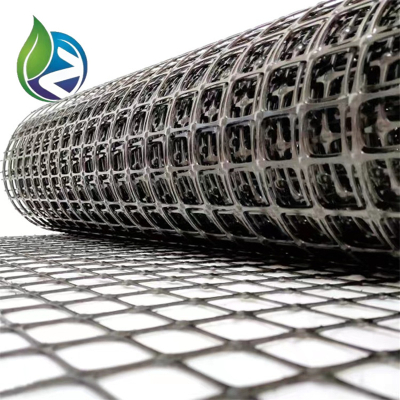

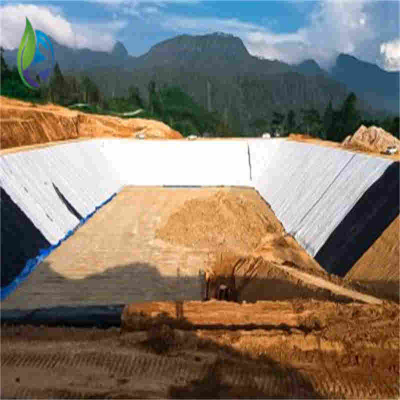

An HDPE Geocell (High-Density Polyethylene Geocell) is a three-dimensional honeycomb-like cellular confinement system. It's made from high-strength HDPE strips that are ultrasonically welded together and expanded onsite to form a grid structure. This cellular matrix confines soil or aggregate, drastically improving load distribution and preventing lateral movement.

“I’ve used HDPE geocells for both gravel roads and steep embankments. They outperform traditional methods and reduce material costs significantly.”

— Robert D., Civil Engineer (User Review)

Key Benefits of HDPE Geocell in Modern Construction

✅ 1. Superior Load Distribution

The interlocking honeycomb structure of an HDPE geocell distributes loads evenly across a wider area, making it ideal for soft soil or unstable terrain.

✅ 2. Erosion Control

Whether it’s a steep slope or riverbank, HDPE geocells anchor the soil and prevent it from washing away, even during heavy rains or floods.

✅ 3. Cost-Efficient and Lightweight

Unlike concrete or rock structures, HDPE geocell systems are lightweight, easy to transport, and reduce the need for deep excavation or high-cost materials.

✅ 4. Eco-Friendly Construction

By using locally available fill (even recycled materials), HDPE geocell installations reduce the carbon footprint of infrastructure projects and promote sustainability.

Where Can You Use HDPE Geocell?

1. Road and Pavement Reinforcement

From haul roads to driveways, HDPE geocell reinforces base layers and prevents rutting and potholes under heavy traffic.

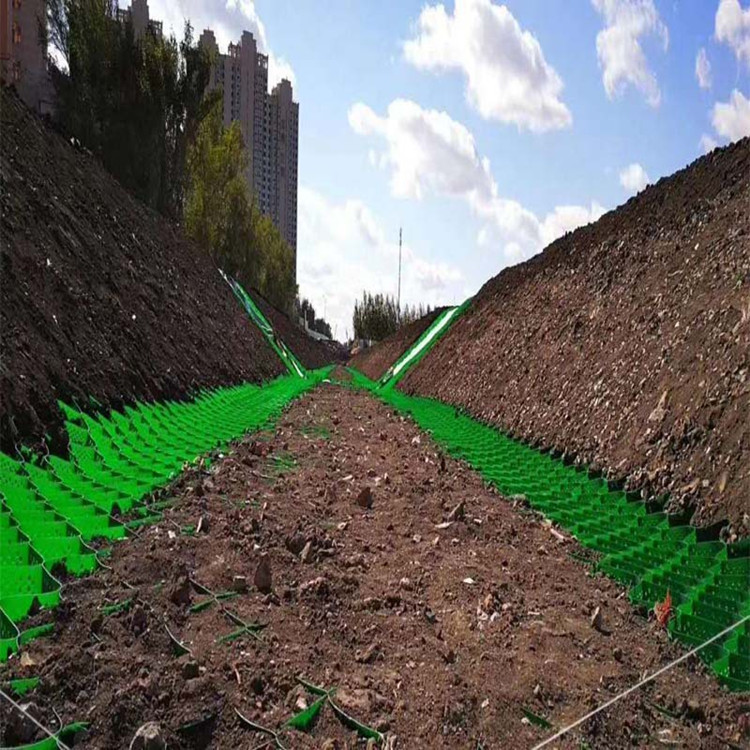

2. Slope and Embankment Stabilization

Perfect for preventing landslides and erosion in hilly terrains, highway cut slopes, and mining areas.

3. Channel and Drainage Protection

HDPE geocell lines and stabilizes water channels, reducing flow velocity and protecting against scouring.

4. Retaining Wall Systems

When combined with geogrid or vegetation, geocells form gravity walls that are both functional and green.

“We installed HDPE geocells on a 45° slope with grass seeding. Two seasons in, the slope is green, firm, and fully erosion-resistant.”

— Emily H., Landscape Contractor (User Review)

How to Install HDPE Geocell: A Quick Guide

Site Prep: Remove debris and level the subgrade.

Expand & Anchor: Unfold the HDPE geocell, stretch it to its full dimensions, and anchor it with stakes or rebar.

Fill the Cells: Use local soil, gravel, or recycled material. Compact each layer.

Top It Off: Cap with vegetation, asphalt, or concrete as per design requirements.

"Installation was surprisingly fast. The HDPE geocell sections snapped together easily and held their shape through filling and compaction."

— Martin Y., Site Supervisor (User Review)

Choosing the Right HDPE Geocell: What to Look For

Thickness and Weld Strength: For heavy-duty applications, look for 1.5mm+ HDPE geocells with high ultrasonic weld strength.

Cell Depth: Deeper cells (100mm–200mm) are ideal for erosion control and load support.

Perforation: Perforated HDPE geocells improve water drainage and root growth in green applications.

UV Resistance: For exposed installations, UV-stabilized material is a must for long-term durability.

Frequently Asked Questions About HDPE Geocell

Q: Can HDPE geocells be reused?

A: In some temporary projects, yes. But typically, they’re installed as a permanent structural component.

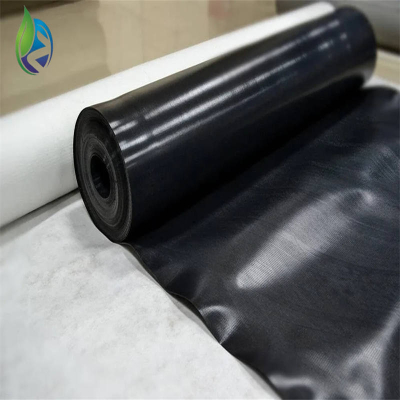

Q: Do HDPE geocells require geotextile underneath?

A: Yes, especially on soft soils, a geotextile layer below prevents mixing and adds filtration benefits.

Q: Are they suitable for cold climates?

A: Absolutely. HDPE is chemically inert and performs reliably in sub-zero temperatures.

Final Thoughts: Why HDPE Geocell is the Future of Ground Engineering

The demand for sustainable, cost-effective, and high-performance ground reinforcement is growing—and HDPE Geocell systems meet all three criteria. Whether for rural access roads, military bases, or urban landscaping, these high-density polyethylene grids are proving to be one of the most versatile tools in the civil engineering toolbox.

No concrete? No problem. HDPE geocells are here to reshape how we build—literally and sustainably.

Have you used HDPE geocell in your project? Share your experience below!

Need product specs or installation help? Message us—we’re happy to assist with your design needs.