HDPE Fish Tank Plastic Membrane

As global demand for efficient aquaculture systems continues to rise, high-performance containment materials have become essential for water management, biosecurity, and long-term operational stability. Among these materials, HDPE fish tank plastic membrane stands out as a durable, cost-effective, and environmentally compliant solution for ponds, tanks, raceways, and intensive RAS (Recirculating Aquaculture System) facilities.

HDPE Fish Tank Plastic Membrane: A Comprehensive Technical Guide for Modern Aquaculture Systems

As global demand for efficient aquaculture systems continues to rise, high-performance containment materials have become essential for water management, biosecurity, and long-term operational stability. Among these materials, HDPE fish tank plastic membrane stands out as a durable, cost-effective, and environmentally compliant solution for ponds, tanks, raceways, and intensive RAS (Recirculating Aquaculture System) facilities.

Global Market Outlook for HDPE Aquaculture Membranes

The aquaculture industry has experienced steady expansion, driven by the increasing global demand for fish protein and the modernization of farming systems. Research suggests that the aquaculture sector will exceed USD 350 billion by 2030, with a growing portion dedicated to intensive farming technologies such as liner-based ponds and modular tank systems.

The demand for HDPE fish tank plastic membrane has accelerated due to:

The need for controlled water environments

Increased focus on disease prevention and biosecurity

Rising adoption of RAS and pond lining systems

Government support for sustainable aquaculture

Efficiency gains from reducing seepage, contamination, and water loss

As a result, HDPE membrane is becoming a standard material across commercial farms, hatcheries, and aquaculture infrastructure projects.

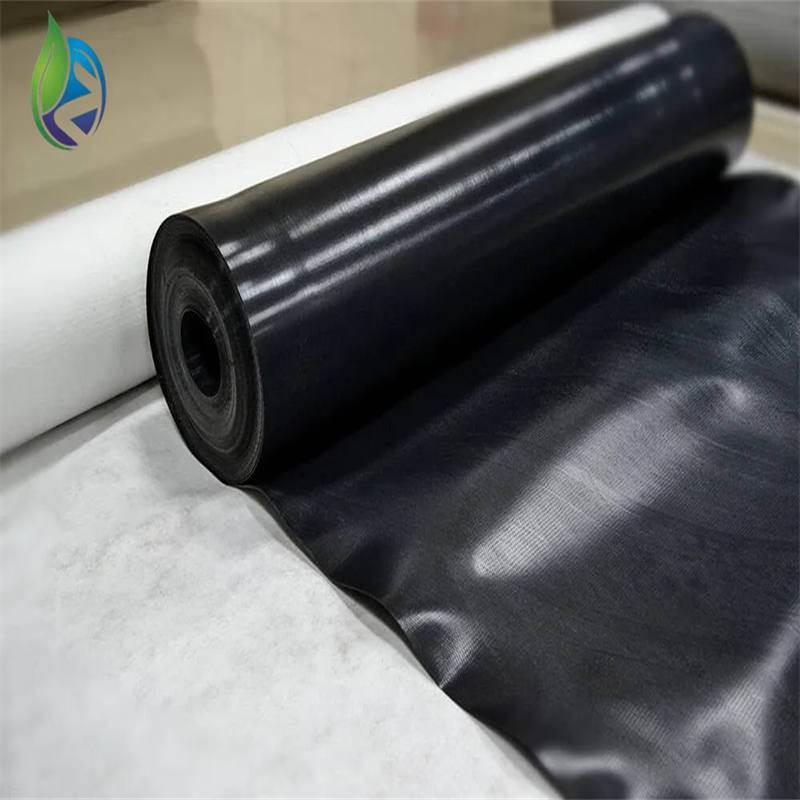

What Is HDPE Fish Tank Plastic Membrane?

HDPE fish tank plastic membrane is a high-density polyethylene geomembrane designed for water containment applications in aquaculture. It provides exceptional impermeability, chemical resistance, and long-term performance under varying environmental conditions.

Key Features

Material: High-density polyethylene (HDPE)

Thickness: Typically 0.3 mm to 2.0 mm, depending on application

Color: Standard black, UV-stabilized

Performance: Strong puncture resistance, anti-seepage, anti-corrosion

Applications: Fish tanks, ponds, grow-out systems, hatcheries, water reservoirs

Due to its flexibility and superior longevity, HDPE membrane is now widely used as a cost-effective alternative to concrete ponds or traditional clay-lined ponds.

Technical Advantages of HDPE Fish Tank Plastic Membrane

1. Superior Impermeability

HDPE geomembrane provides near-zero water seepage, enabling farmers to maintain consistent pond water levels and reduce operational water costs.

2. High Chemical and Biological Resistance

The membrane is resistant to:

Organic acids

Fish waste

Alkaline conditions

Fertilizers and disinfectants

Microbial growth

This protects both fish health and infrastructure.

3. Longer Service Life and UV Protection

HDPE membranes typically have a service life of 10–20 years, thanks to their resistance to UV radiation, oxidation, and thermal aging.

4. Easy Cleaning and Improved Hygiene

Smooth surfaces allow faster removal of sludge and organic matter, resulting in better biosecurity and reduced disease outbreaks.

5. Cost Efficiency for Large-Scale Aquaculture

HDPE fish tank plastic membrane significantly reduces construction time and overall project cost compared to concrete tanks or natural ponds.

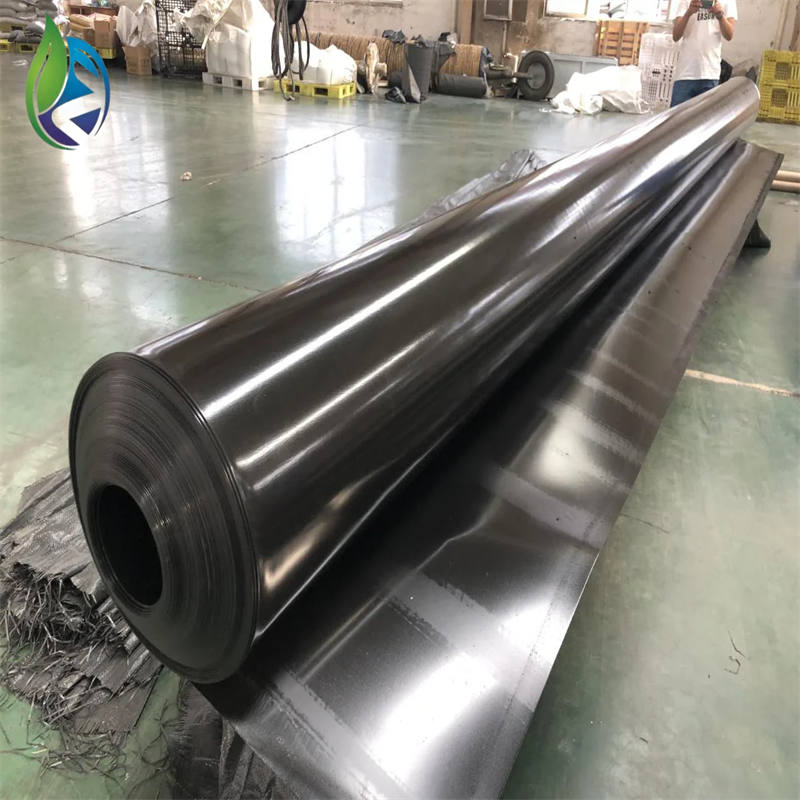

Manufacturing Process of HDPE Membrane

High-quality HDPE fish tank plastic membrane is produced using advanced extrusion and calendaring technologies:

1. Raw Material Processing

Virgin HDPE resin is mixed with antioxidants and UV stabilizers to enhance outdoor performance.

2. Film Extrusion

The mixture is melted and extruded into a uniform sheet through a blown or flat-die extrusion process.

3. Cooling and Thickness Calibration

Precision rollers ensure consistent thickness across the entire width of the membrane.

4. Surface Texturing

Optional texturing can be applied to enhance friction in sloped tank or pond designs.

5. Quality Testing

Each batch undergoes rigorous testing for:

Tensile strength

Tear resistance

Puncture resistance

Impermeability

UV aging performance

This ensures compliance with international geomembrane standards.

Applications in Modern Aquaculture Systems

Lined Fish Ponds

HDPE membrane prevents water loss and contamination, providing stable conditions for tilapia, catfish, carp, and shrimp farming.

Round or Square Fish Tanks

Used in RAS systems, hatcheries, nurseries, and fish grading centers.

Biofloc Tanks

HDPE acts as a clean, non-reactive lining material suitable for BFT systems.

Water Storage Reservoirs

Ideal for farms requiring stable water sources for constant flow aquaculture.

Irrigation and Farm Infrastructure

Membrane-lined reservoirs support integrated aquaculture-agriculture models.

Market Trends Driving Adoption

Transition to Intensive Farming

Producers are shifting from extensive ponds to controlled tank systems for higher yield.

Government Programs Supporting Liner-Based Ponds

Many countries offer subsidies for HDPE lined ponds to improve food security.

Rising Awareness of Biosecurity

Membranes allow better control of parasites, pathogens, and environmental contamination.

Preference for Smart, Modular Aquaculture

HDPE-lined tanks are essential components of portable, scalable farming units.

Choosing the Right HDPE Membrane for Aquaculture

When selecting HDPE fish tank plastic membrane, buyers should evaluate:

Thickness (0.5 mm for small tanks, 1.0–1.5 mm for large ponds)

Tensile strength requirements

UV stability level for outdoor applications

Texture (smooth or rough surface)

Expected lifespan

Installation method compatibility

For large-scale projects, custom fabrication and prefabricated tank liners can significantly reduce on-site installation time.

Frequently Asked Questions (FAQ)

1. What thickness is recommended for HDPE fish tanks?

For small tanks, 0.5–0.75 mm is common. Large ponds or commercial tanks typically use 1.0–1.5 mm for maximum strength and durability.

2. Can HDPE membrane be used in saltwater systems?

Yes. HDPE is chemically resistant and performs well in both freshwater and marine environments.

3. How long does HDPE fish tank plastic membrane last?

Service life ranges from 10 to 20 years depending on UV exposure, thickness, and installation conditions.

4. Is HDPE safe for fish and aquatic plants?

Yes. Food-grade HDPE is non-toxic, chemically stable, and safe for aquaculture use.

Conclusion: HDPE Fish Tank Plastic Membrane as a Reliable Aquaculture Solution

With its unmatched impermeability, structural strength, chemical resistance, and long service life, HDPE fish tank plastic membrane has become essential for modern aquaculture. It supports improved water quality, higher production efficiency, and more reliable long-term operation—making it a trusted choice across global fish farming projects.

Professional Call to Action

We supply high-quality HDPE fish tank plastic membrane designed for commercial aquaculture, with customized sizes, technical support, and global export capability. Contact our engineering team for datasheets, quotations, or project-based recommendations. Enhance your farm’s performance with reliable membrane lining solutions.