Fiber glass geogrid

Glass fiber grating can improve the high temperature rutting resistance of asphalt concrete pavement, delay the crack of asphalt concrete pavement, and reduce the thickness of asphalt layer. The main function of the glass fiber grating is to improve the wear resistance and shear ability of the geogrid. Glass fiber grille can be widely used in old cement pavement, airport runway maintenance, embankment, bank, slope protection, road bridge pavement enhancement treatment and other engineering fields, can enhance and reinforce the road surface, prevent road rutting fatigue cracks, hot and cold expansion cracks and the following reflection cracks, and can disperse the road bearing stress, extend the service life of the road surface.

In today's demanding construction environment, reinforcement materials must be strong, durable, and cost-effective. Among the most trusted solutions, Fiber Glass Geogrid stands out as a high-performance reinforcement grid designed to extend pavement life, minimize cracking, and boost structural integrity. With unmatched stability and ease of installation, Fiber Glass Geogrid is quickly becoming the preferred choice for engineers and contractors worldwide.

What Is Fiber Glass Geogrid?

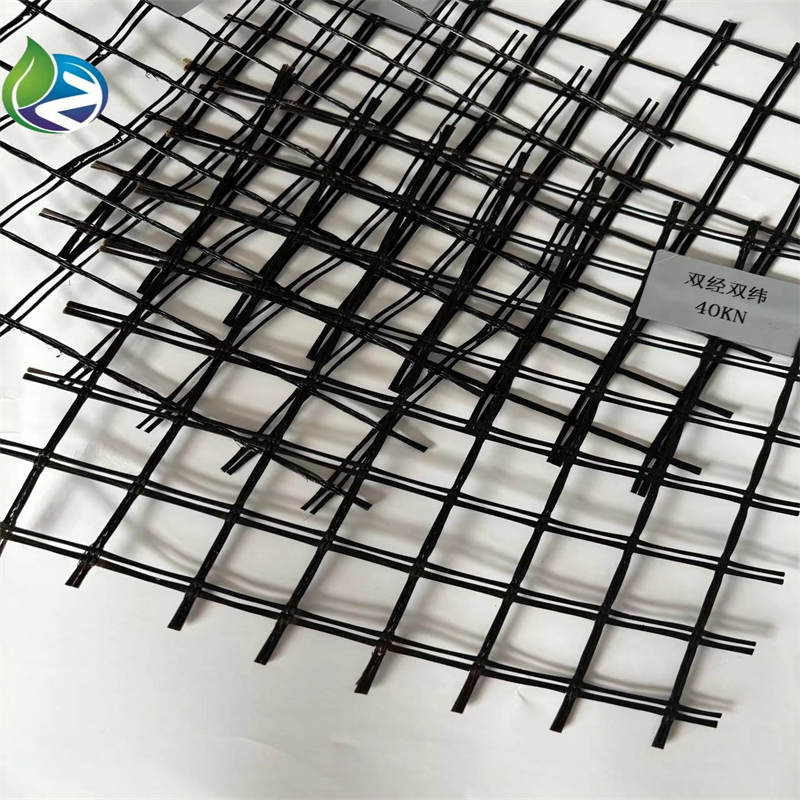

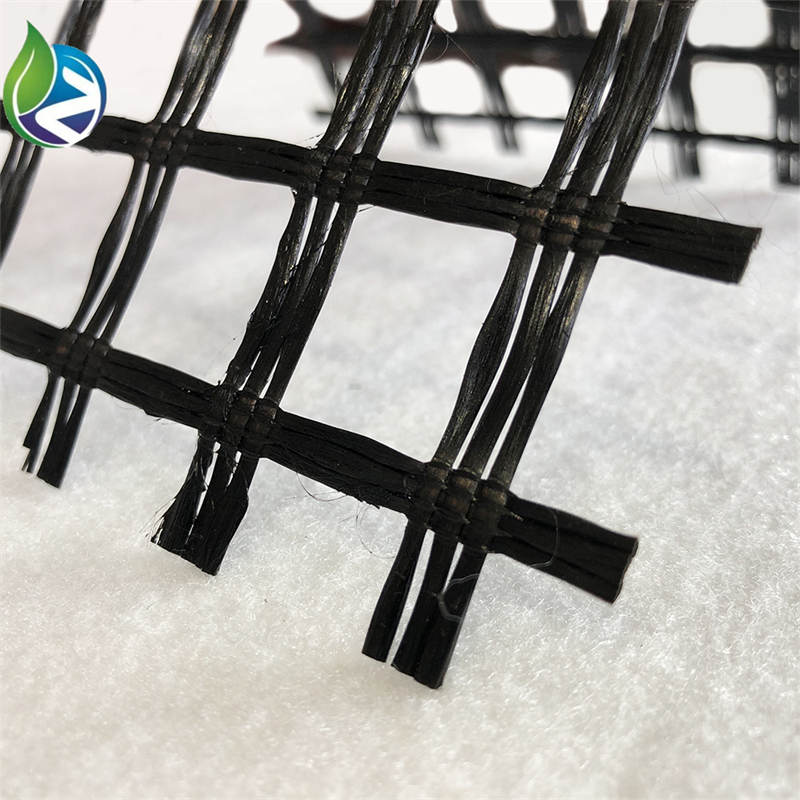

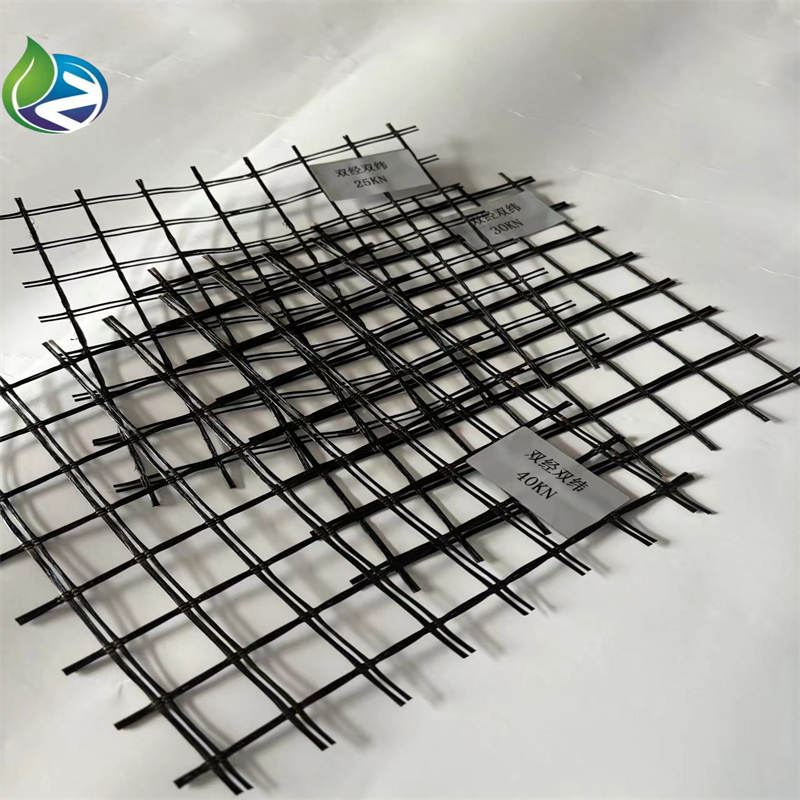

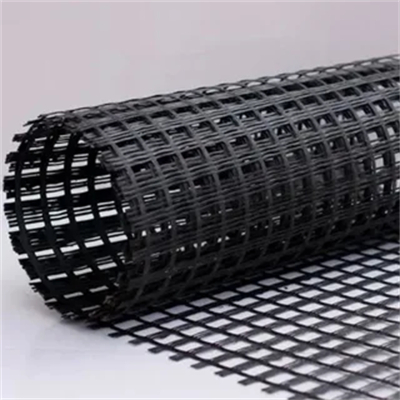

Fiber Glass Geogrid is a geosynthetic material composed of high-strength fiberglass yarns coated with a polymer such as PVC or bitumen. Its grid-like structure is engineered to resist deformation and distribute loads effectively across pavement layers, making it an essential reinforcement product for road construction, asphalt overlays, retaining walls, and more.

Manufactured using advanced knitting and coating technologies, Fiber Glass Geogrid delivers exceptional tensile strength, dimensional stability, and chemical resistance—all essential for challenging soil and pavement conditions.

Top Features of Fiber Glass Geogrid

High Tensile Strength

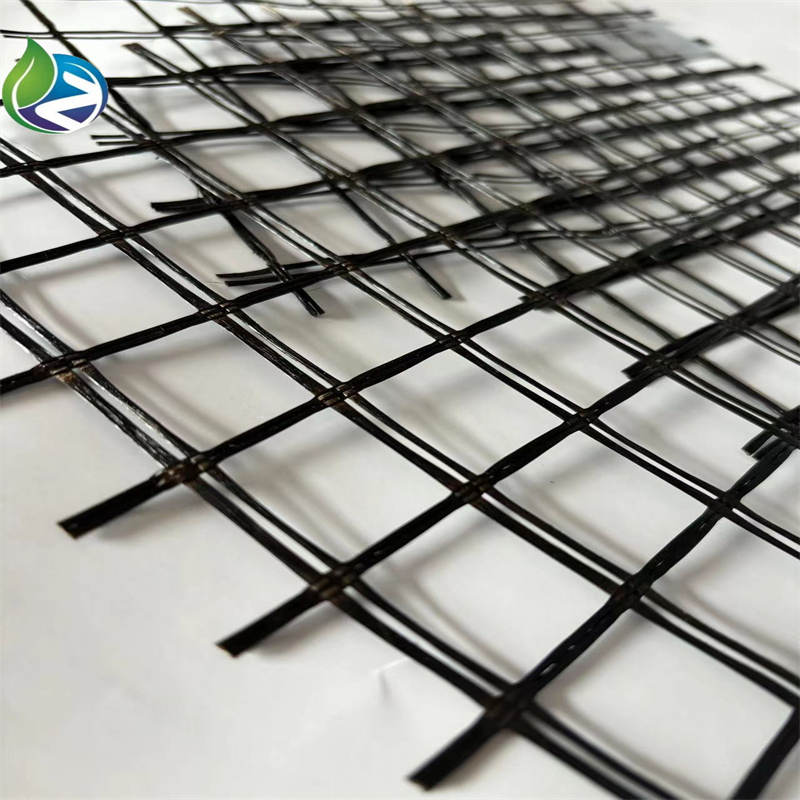

The core advantage of Fiber Glass Geogrid is its outstanding tensile strength both longitudinally and transversely, which helps distribute loads and delay reflective cracking.Superior Dimensional Stability

With minimal elongation under load, Fiber Glass Geogrid maintains its shape even in high-temperature or high-stress environments, reducing the risk of rutting and shifting.Asphalt Compatibility

Special coatings enhance bonding between the Fiber Glass Geogrid and asphalt layers, preventing slippage and ensuring uniform performance across the pavement structure.Corrosion and UV Resistance

Unlike steel reinforcement, Fiber Glass Geogrid is non-corrosive and UV-stable, allowing for long-term performance even in exposed or chemically aggressive environments.Easy Installation

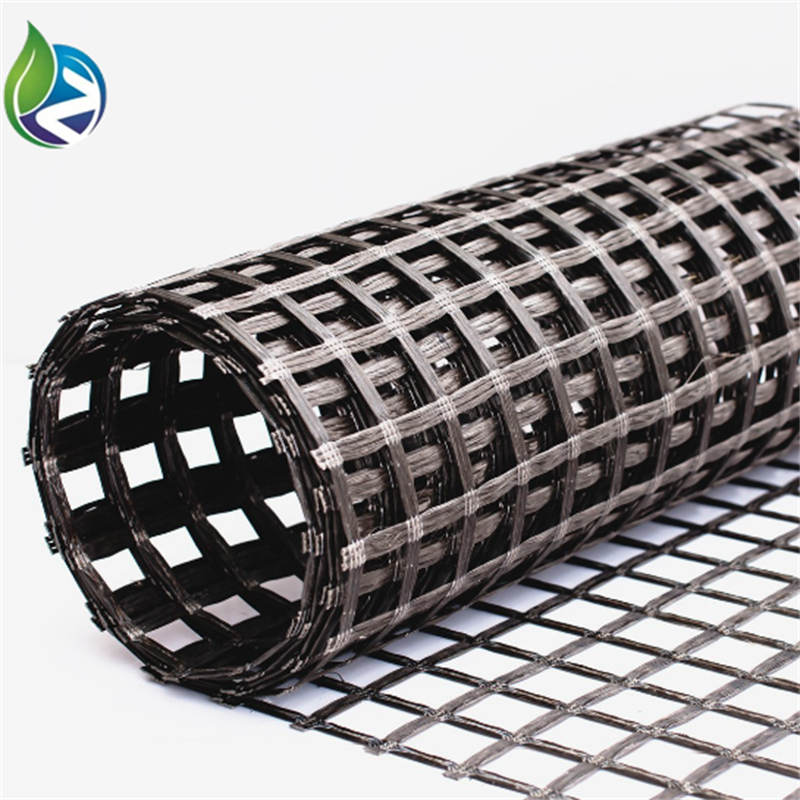

Lightweight and flexible, Fiber Glass Geogrid can be laid quickly over existing surfaces, cutting labor costs and speeding up construction timelines.

Main Applications of Fiber Glass Geogrid

Thanks to its versatility and strength, Fiber Glass Geogrid is widely used in:

Asphalt pavement reinforcement

Concrete road overlays

Airport runway and taxiway improvements

Retaining wall stabilization

Slope protection and embankment support

Parking lot construction and rehabilitation

Each of these applications benefits from the geogrid's ability to reduce reflective cracking, improve load distribution, and extend the overall service life of the structure.

Why Choose Fiber Glass Geogrid for Your Next Project?

Choosing the right reinforcement is crucial to the success of any infrastructure project. Fiber Glass Geogrid offers a range of advantages that make it the go-to solution:

Reduces maintenance costs by extending pavement life

Enhances structural performance with minimal thickness

Improves bearing capacity of weak soils

Compatible with various paving materials

Backed by proven results in real-world conditions

Whether you're tackling a major highway project or a municipal road overlay, Fiber Glass Geogrid delivers results that translate to lower lifecycle costs and greater project efficiency.

Installation Best Practices

To get the most from Fiber Glass Geogrid, follow these guidelines:

Ensure a clean, dry surface free of debris

Unroll the geogrid smoothly with no wrinkles or folds

Secure with tack coat or mechanical fastening as needed

Overlay with asphalt or fill material promptly after placement

Proper installation ensures the geogrid performs as intended and integrates seamlessly with the pavement or soil structure.

Conclusion

Fiber Glass Geogrid is revolutionizing modern construction by offering a lightweight, strong, and cost-effective reinforcement solution. Its ability to minimize cracking, support heavy loads, and increase pavement lifespan makes it a smart investment for any civil engineering project.

When performance, durability, and cost-efficiency matter most, Fiber Glass Geogrid is the reinforcement material you can count on.