Biaxial Plastic Geogrid for Road

Manufacturing Process

Biaxial plastic geogrids are manufactured through a controlled, engineering-grade extrusion and orientation process.

Polymer raw material blending with stabilizers and additives.

Sheet extrusion through precision flat dies.

Punching or forming of regular aperture patterns.

Biaxial stretching under controlled temperature conditions.

Cooling and stabilization to lock molecular orientation.

Quality inspection, tensile testing, and roll packaging.

Product Definition

Biaxial Plastic Geogrid for Road is a polymer-based geosynthetic reinforcement material with tensile strength in both longitudinal and transverse directions, designed to improve load distribution, enhance bearing capacity, and extend service life in road and pavement engineering.

Technical Parameters and Specifications

Biaxial plastic geogrids are specified according to mechanical strength, aperture geometry, and durability requirements for road subgrade and base reinforcement.

| Parameter | Typical Range |

|---|---|

| Polymer Type | PP (Polypropylene) / HDPE |

| Tensile Strength (MD/TD) | 20–50 kN/m |

| Elongation at Break | ≤ 13% |

| Aperture Size | 30 × 30 mm to 65 × 65 mm |

| Junction Strength | ≥ 90% of tensile strength |

| Carbon Black Content | 2.0–2.5% |

| Design Life | ≥ 50 years (buried conditions) |

Structure and Material Composition

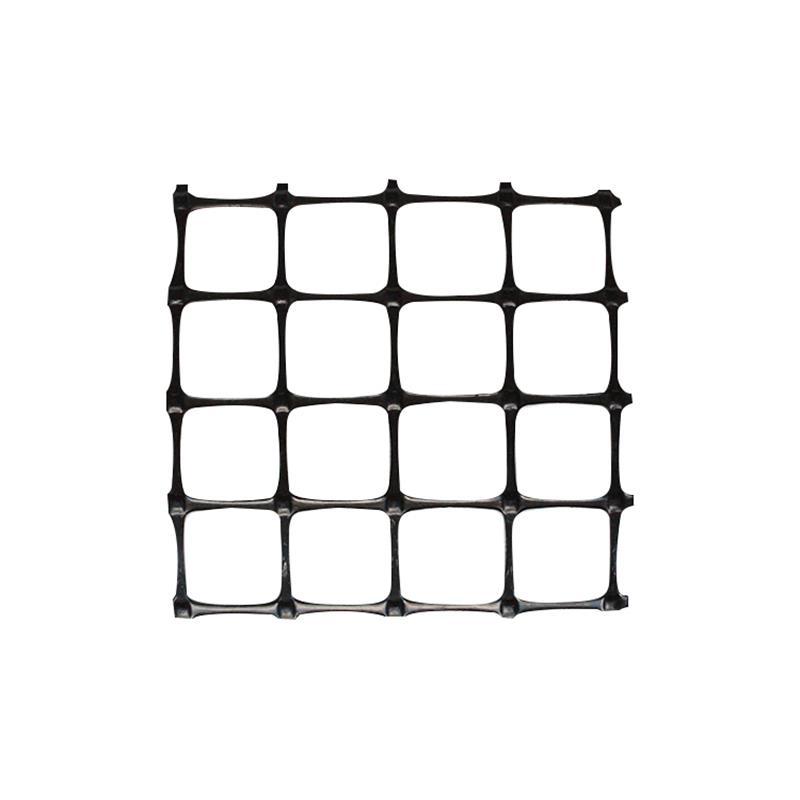

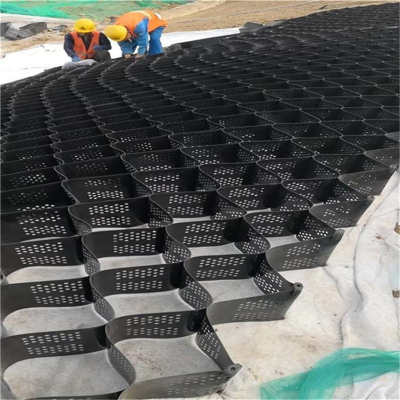

The biaxial plastic geogrid for road reinforcement features an integrated grid structure optimized for interlock with granular materials.

Polymer Sheet: Extruded polypropylene or HDPE base material.

Biaxial Stretching: Oriented in both machine and transverse directions.

Grid Apertures: Square or rectangular openings for aggregate confinement.

Integral Nodes: High-strength junctions ensuring load transfer.

UV Stabilizers: Carbon black additives for durability during installation.

Manufacturing Process

Biaxial plastic geogrids are manufactured through a controlled, engineering-grade extrusion and orientation process.

Polymer raw material blending with stabilizers and additives.

Sheet extrusion through precision flat dies.

Punching or forming of regular aperture patterns.

Biaxial stretching under controlled temperature conditions.

Cooling and stabilization to lock molecular orientation.

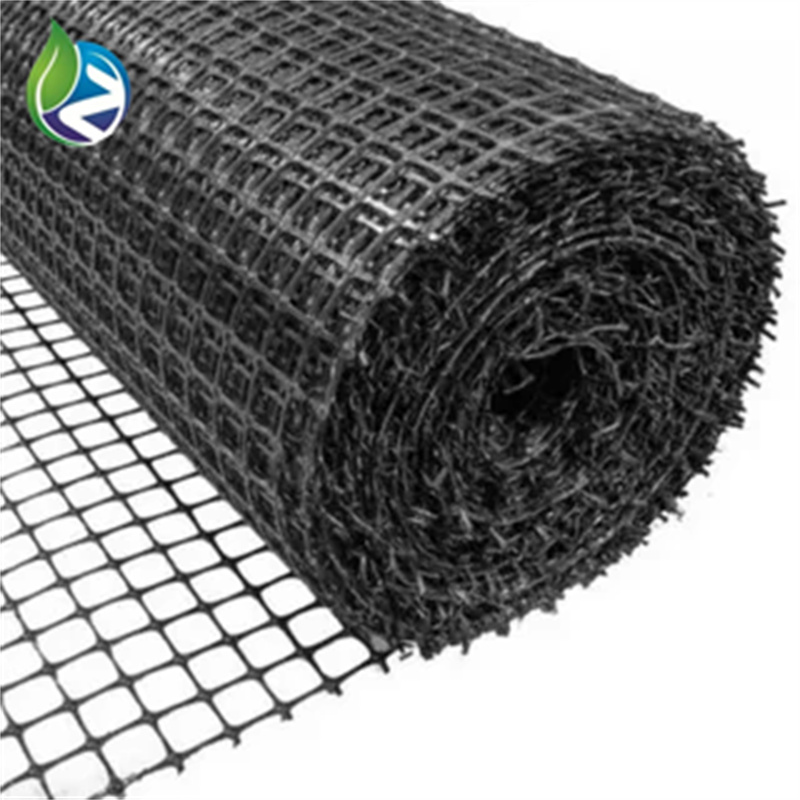

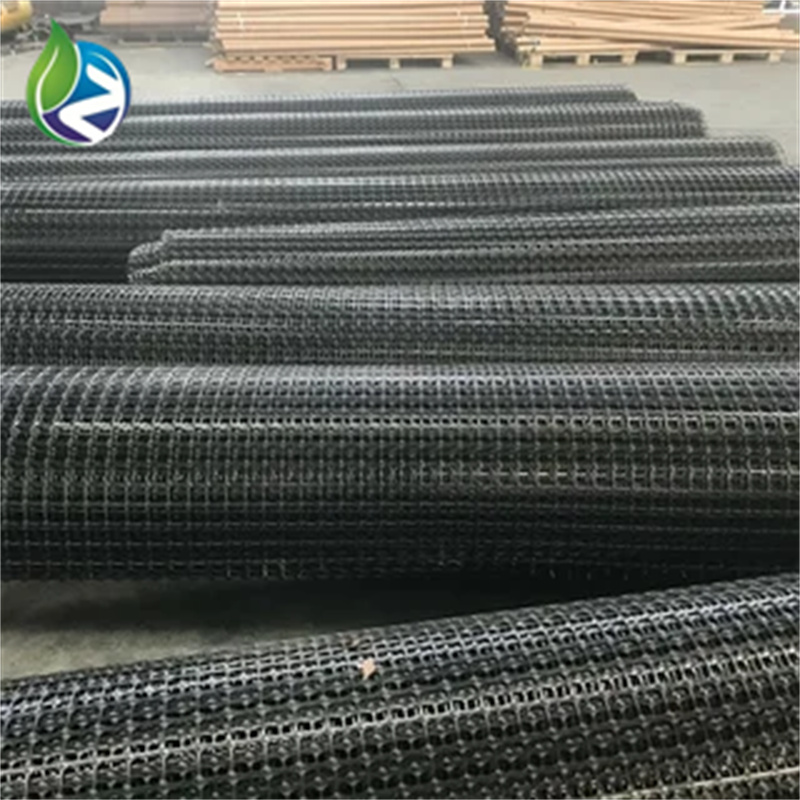

Quality inspection, tensile testing, and roll packaging.

Industry Comparison

| Material Type | Reinforcement Efficiency | Cost Effectiveness | Installation Complexity | Typical Applications |

|---|---|---|---|---|

| Biaxial Plastic Geogrid | High | High | Low | Road base & subgrade |

| Uniaxial Geogrid | Directional | Medium | Medium | Retaining structures |

| Geotextile Fabric | Low–Medium | High | Low | Separation & filtration |

| Crushed Stone Only | Low | Low | Low | Traditional road base |

Application Scenarios

Biaxial plastic geogrid for road construction is widely adopted by:

Road and highway EPC contractors

Municipal infrastructure developers

Industrial park and logistics zone builders

Distributors of geotechnical materials

Engineering consultants specifying pavement structures

Core Pain Points and Solutions

Weak subgrade bearing capacity: Geogrid improves load distribution and confinement.

Rutting and deformation: Biaxial tensile reinforcement limits lateral aggregate movement.

High maintenance costs: Extended pavement life reduces lifecycle expenditure.

Excessive base thickness: Reinforcement allows reduced aggregate layer depth.

Risk Warnings and Mitigation Recommendations

Avoid prolonged UV exposure before backfilling.

Ensure correct orientation and full tension-free placement.

Prevent damage from sharp aggregates during installation.

Verify compatibility with local soil and aggregate gradation.

Procurement and Selection Guide

Assess subgrade CBR and soil classification.

Determine required tensile strength based on traffic load.

Select appropriate aperture size for aggregate interlock.

Confirm long-term creep and durability data.

Review compliance with relevant road engineering standards.

Evaluate supplier production capacity and quality control systems.

Engineering Application Example

In a secondary highway upgrade project spanning 18 km, a biaxial plastic geogrid with 30 kN/m tensile strength was installed between subgrade and crushed stone base. The design reduced base thickness by 20% and achieved measurable improvements in rut resistance under heavy truck traffic.

Frequently Asked Questions (FAQ)

What is the primary function of biaxial geogrid in roads? Load distribution and reinforcement.

Is biaxial geogrid suitable for soft soil subgrades? Yes, when properly designed.

How long does biaxial plastic geogrid last? Typically over 50 years in buried conditions.

Can it replace traditional base layers? It complements and optimizes base layers.

Does it require overlap during installation? Yes, usually 30–50 cm depending on design.

Is special equipment needed for installation? No, standard construction equipment is sufficient.

What standards apply? Commonly ASTM, EN, and local highway specifications.

Can it be used with recycled aggregates? Yes, with proper gradation control.

Does it provide drainage? No, it primarily provides reinforcement.

How is quality verified on site? Through tensile tests and visual inspection.

Call to Action

For road engineering tenders, technical datasheets, design support, or project-specific quotations for biaxial plastic geogrid for road applications, procurement and engineering teams are invited to submit formal requests for evaluation.

E-E-A-T Author Credentials

This article is authored by a geotechnical engineering specialist with extensive experience in geosynthetics selection, road reinforcement design, and international infrastructure projects, providing authoritative and reliable guidance for B2B decision-makers.