High Tensile Steel Plastic Geogrid

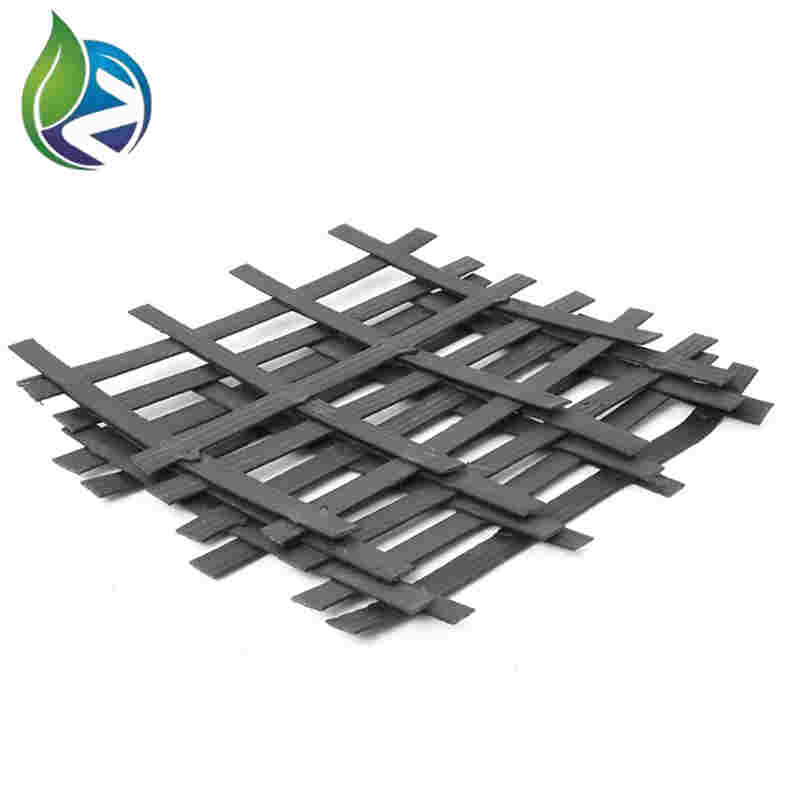

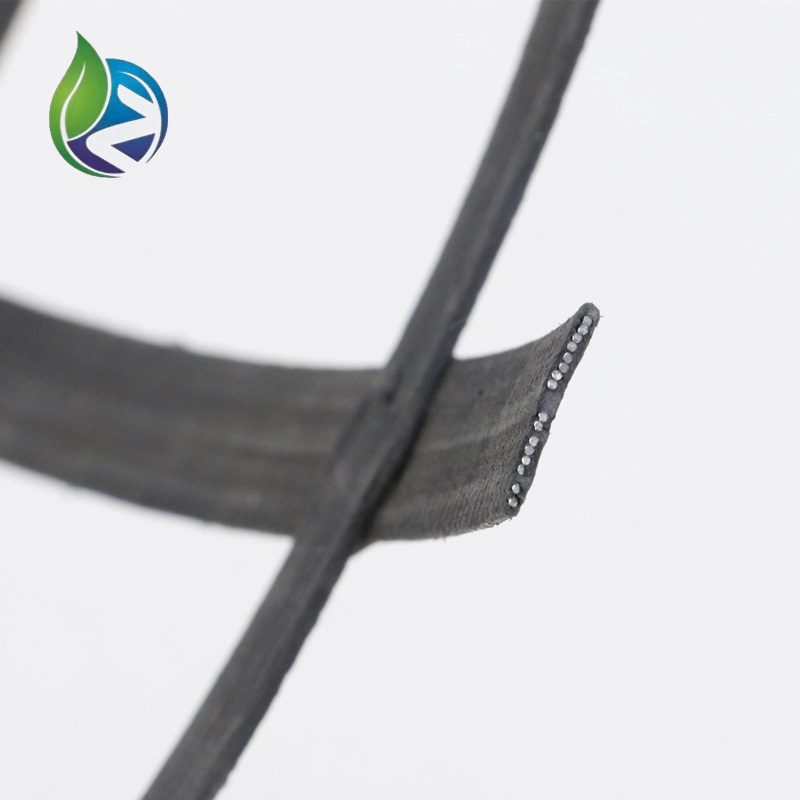

Steel plastic geogrid is a high-performance, composite material widely utilized in various civil engineering projects. It is crafted from a blend of high-tensile steel wire (or other fibers) and polyethylene (PE) or polypropylene (PP), along with other additives, through a process of special treatment and extrusion. This results in a robust, anti-pull belt that is further strengthened through ultrasonic welding technology, forming a reinforced grid structure.This geogrid boasts numerous benefits, including its high strength and low deformation, making it suitable for a range of environments and able to withstand the demands of tall retaining walls in high-grade highways. Its corrosion resistance and long service life are also noteworthy, as the plastic coating and additives provide anti-aging and anti-oxidation properties, resisting harsh environments like acid, alkali, and salt.

High Tensile Strength Steel Plastic Geogrid for Highway Reinforcement

High tensile strength steel plastic geogrid for highway reinforcement is a specially engineered geosynthetic material designed to improve the structural performance and stability of roadbeds and highway embankments. By combining the superior rigidity of steel wires with the durability of plastic polymers, high tensile strength steel plastic geogrid for highway reinforcement delivers unmatched load-bearing capacity, reduced deformation, and long-lasting reinforcement under dynamic traffic conditions.

What Is High Tensile Strength Steel Plastic Geogrid for Highway Reinforcement?

High tensile strength steel plastic geogrid for highway reinforcement consists of high-strength steel wires encapsulated in polyethylene or polypropylene plastic through extrusion and welding processes. The composite grid structure offers high tensile strength in both longitudinal and transverse directions, making it ideal for high-load infrastructure applications.

Key properties:

Excellent resistance to tensile and shear forces

Enhanced bonding with base materials

Anti-corrosion and chemical resistance

Long service life in harsh conditions

Because of these features, high tensile strength steel plastic geogrid for highway reinforcement is widely adopted in modern road construction and rehabilitation.

Features of High Tensile Strength Steel Plastic Geogrid for Highway Reinforcement

Superior Load Distribution

The grid structure of the high tensile strength steel plastic geogrid for highway reinforcement distributes vehicle loads more evenly across soft or unstable subgrades, minimizing rutting and settlement.Exceptional Tensile Strength

With tensile strength exceeding 50–100 kN/m (depending on design), high tensile strength steel plastic geogrid for highway reinforcement meets demanding engineering requirements for heavy-duty roadways.Durability in Harsh Environments

The protective plastic coating shields the steel wires from corrosion, UV damage, and chemical attack, allowing the high tensile strength steel plastic geogrid for highway reinforcement to perform reliably over decades.Strong Interlock with Soil and Aggregate

The open-grid mesh provides excellent interlocking with granular materials, increasing the composite strength of the road base when using high tensile strength steel plastic geogrid for highway reinforcement.Time and Cost Savings

By reinforcing weak soils and reducing base thickness requirements, high tensile strength steel plastic geogrid for highway reinforcement helps shorten construction schedules and reduce material costs.

Applications of High Tensile Strength Steel Plastic Geogrid for Highway Reinforcement

High tensile strength steel plastic geogrid for highway reinforcement is suitable for a range of civil and transportation engineering projects:

Highways and expressways

Airport runways and taxiways

Bridge approach embankments

Railway trackbed stabilization

Port and container yard foundations

Urban and rural road upgrades

In each application, high tensile strength steel plastic geogrid for highway reinforcement enhances safety, stability, and long-term performance.

Installation Guidance

Proper installation of high tensile strength steel plastic geogrid for highway reinforcement ensures optimal performance:

Prepare the subgrade and remove any debris or weak materials.

Unroll the geogrid over the compacted base with minimal overlap (typically 15–30 cm).

Secure the edges using pins or staples.

Place the aggregate base over the geogrid in controlled layers.

Compact thoroughly to create a stable composite structure.

Why Choose High Tensile Strength Steel Plastic Geogrid for Highway Reinforcement?

Choosing high tensile strength steel plastic geogrid for highway reinforcement offers key advantages:

Proven structural support under repetitive traffic loads

Long-term durability in aggressive soil and weather conditions

Cost-effective alternative to traditional base reinforcement methods

Reduced maintenance and road surface failure risks

Engineers and contractors rely on high tensile strength steel plastic geogrid for highway reinforcement for high-performance, sustainable road infrastructure.

Conclusion

The high tensile strength steel plastic geogrid for highway reinforcement is a powerful solution for modern highway construction. Its unique combination of steel strength and plastic resilience makes it an indispensable material for enhancing road stability, longevity, and load capacity. When you need reliable and efficient subgrade reinforcement, high tensile strength steel plastic geogrid for highway reinforcement delivers results that last.