High quality steel-plastic geogrid

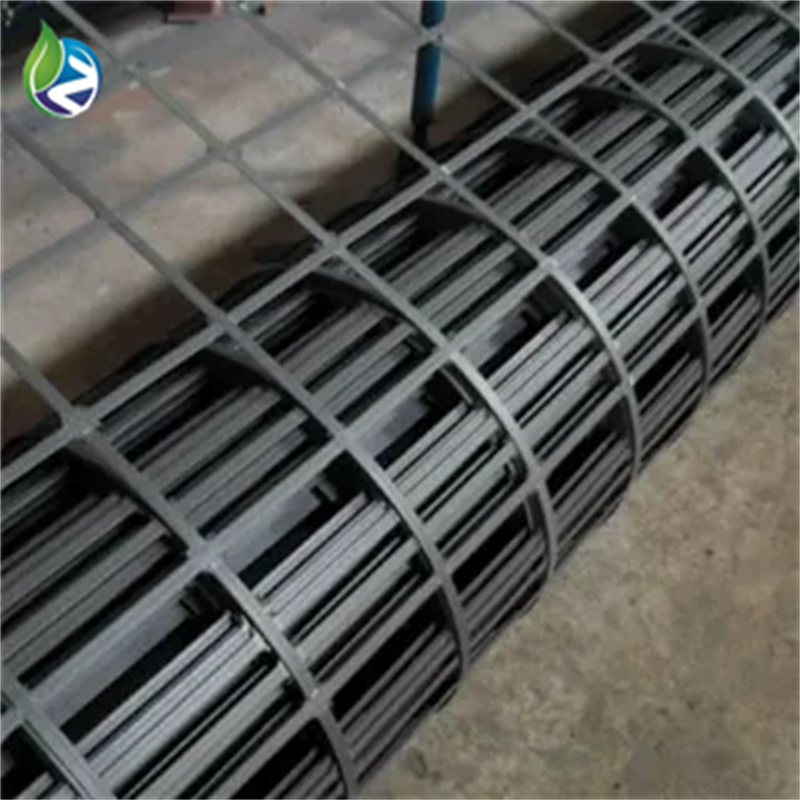

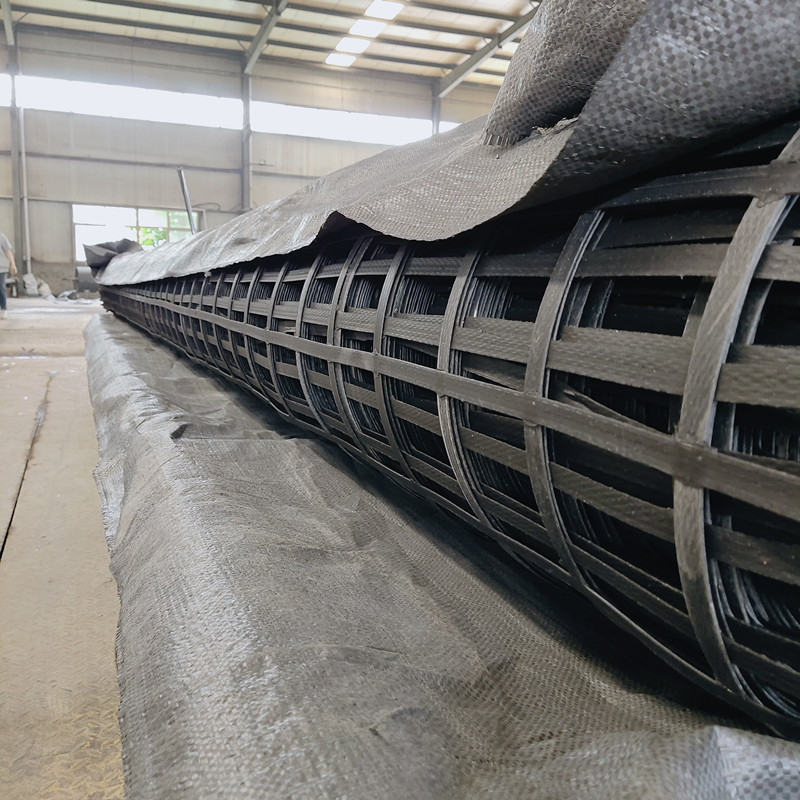

The full name of the steel-plastic grille is steel-plastic composite geogrid. Is a high-strength steel wire (or other fibers). after special treatment. with polyethylene (PE). and add other additives. by extrusion to become a composite high-strength tensile strip. and the surface has rough embossed. is a high-strength reinforced earth belt.

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

When it comes to advanced geotechnical engineering and foundation stability, high quality steel-plastic geogrid is a proven material that delivers exceptional tensile strength, durability, and structural reinforcement. This innovative product combines the high tensile strength of steel with the corrosion-resistant properties of plastic, making it ideal for roads, railways, retaining walls, and embankments.

What is a High Quality Steel-Plastic Geogrid?

A high quality steel-plastic geogrid is a geosynthetic material composed of high-strength steel wires coated with polyethylene or polypropylene. These wires are uniformly arranged and welded into a grid structure, which is then encased in a durable polymer matrix. This combination allows for maximum performance in demanding environments.

The key advantage of using high quality steel-plastic geogrid lies in its dual function: reinforcing soft soils while effectively distributing loads across wide areas.

Key Benefits of High Quality Steel-Plastic Geogrid

✅ Unmatched Tensile Strength

The embedded steel wires provide powerful resistance to tensile forces in both longitudinal and transverse directions.

✅ Corrosion and Aging Resistance

Thanks to the protective plastic coating, high quality steel-plastic geogrid performs exceptionally well in acidic, alkaline, or saline soil environments.

✅ Improved Load Distribution

It effectively redistributes loads, reduces rutting, and enhances structural lifespan—perfect for high-traffic roads and heavy-duty industrial foundations.

✅ Extended Service Life

With a lifespan exceeding 50 years in underground applications, it outlasts many traditional reinforcement materials.

✅ Easy to Install and Economical

Its lightweight structure and roll format make transportation and installation fast and cost-effective.

Applications of High Quality Steel-Plastic Geogrid

The versatility of high quality steel-plastic geogrid makes it essential in a wide range of civil and infrastructure projects:

? Highways and Expressways

? Railroad Track Bed Reinforcement

? Retaining Wall Structural Support

? Slope Protection and Landslide Prevention

? Airport Runway Subgrade

? Water Conservancy Projects

? Temporary Access Roads and Work Platforms

Whether you’re building over weak soil or requiring long-term stability under dynamic loading, high quality steel-plastic geogrid delivers robust performance.

Technical Specifications

| Property | Value Range |

|---|---|

| Product Name | High Quality Steel-Plastic Geogrid |

| Material | Steel wires + HDPE/PP coating |

| Mesh Size | 25x25mm / 50x50mm / Custom |

| Tensile Strength | 30–200 kN/m |

| Elongation | < 3% |

| Width | 1m to 4m (customizable) |

| Roll Length | 50m or as required |

| Color | Black / Grey |

| Standard Compliance | GB/T 17689, ASTM D6637, ISO 10319 |

Why Choose High Quality Steel-Plastic Geogrid?

With increasing demand for infrastructure capable of handling higher loads and extreme conditions, high quality steel-plastic geogrid is becoming the go-to solution for engineers worldwide. It’s a product engineered to reduce differential settlement, enhance base stability, and offer long-term economic benefits.

By investing in high quality steel-plastic geogrid, contractors and project managers gain:

✅ Reliable reinforcement under variable soil conditions

✅ Reduced maintenance and lifecycle costs

✅ Faster project completion with minimal excavation

✅ Greater design flexibility in challenging terrains

Installation Tips for Maximum Performance

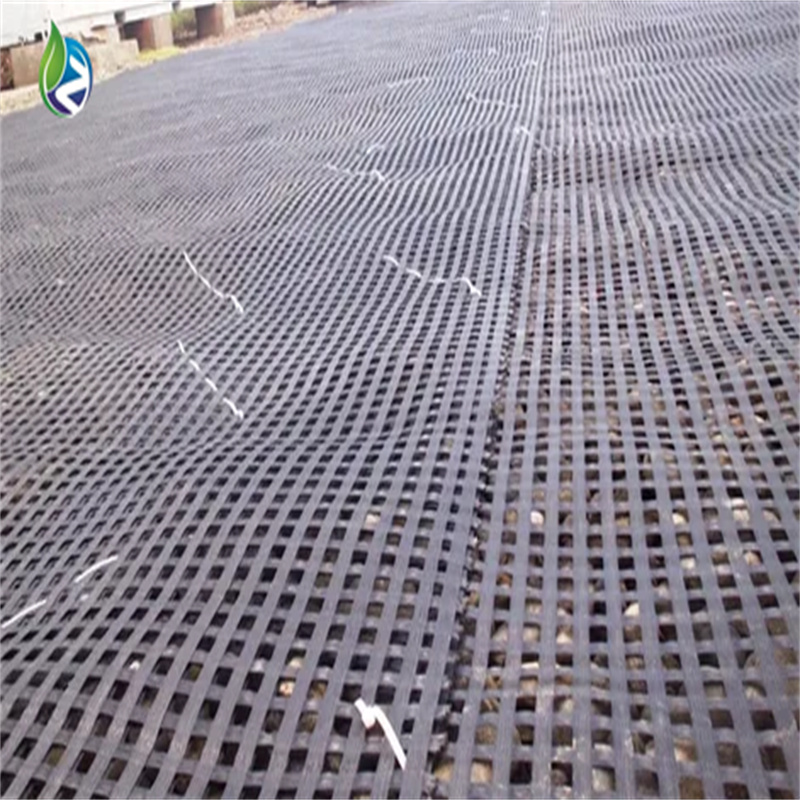

Site Preparation: Clear the subgrade and ensure it is level.

Placement: Unroll the high quality steel-plastic geogrid over the surface with minimal tension.

Anchoring: Fix the edges with U-pins or staples to avoid displacement.

Overlap: Ensure a minimum of 30–50cm overlap between adjacent rolls.

Backfill: Cover with specified granular material and compact in layers.

Proper installation enhances tensile integrity and ensures long-term performance of the geogrid system.

Conclusion

High quality steel-plastic geogrid is a modern geotechnical solution that combines steel’s mechanical superiority with plastic’s durability. It’s the ideal product for soil reinforcement, ground stabilization, and load distribution in infrastructure that demands both strength and sustainability.

Key Features of High-Quality Steel-Plastic Geogrid

Combination of Steel and Plastic

High-quality steel-plastic geogrids are made from a combination of high-tensile steel and durable plastic. The steel provides superior strength and load-bearing capacity, while the plastic adds flexibility, resistance to corrosion, and the ability to withstand harsh environmental conditions. This combination results in a geogrid that is both strong and long-lasting, ideal for reinforcing soil and improving the stability of structures.High Tensile Strength

Steel-plastic geogrids are designed to withstand significant tensile forces, making them ideal for soil reinforcement in areas with heavy loads and traffic. The high tensile strength ensures that the geogrid can provide adequate support to stabilize embankments, roadways, and other infrastructure projects, preventing soil settlement and deformation.Corrosion Resistance

The plastic component of steel-plastic geogrids provides excellent resistance to corrosion, especially in environments exposed to moisture, salts, and chemicals. Unlike traditional steel-only reinforcements, steel-plastic geogrids will not rust or degrade over time, ensuring their long-term performance and durability.Durability in Harsh Conditions

Steel-plastic geogrids are designed to resist UV degradation, temperature fluctuations, and other environmental factors. The robust construction makes them suitable for a wide range of climates and conditions, from hot and dry areas to humid, coastal environments. This durability ensures that the geogrids remain effective over many years, reducing the need for frequent maintenance or replacement.Flexible and Easy to Install

Despite their high tensile strength, steel-plastic geogrids are flexible and lightweight, making them easy to transport and install. The grids can be unrolled and laid over the soil surface with minimal effort, and their interlocking design helps secure them in place, ensuring fast and efficient installation.

Applications of High-Quality Steel-Plastic Geogrid

Road and Railway Construction

Steel-plastic geogrids are commonly used in the construction of roads and railways, where they provide reinforcement to weak soils and improve the load-bearing capacity of the foundations. They are often used to stabilize embankments, prevent rutting, and reduce the risk of settlement, ensuring that roads and railways remain stable and functional even under heavy traffic.Retaining Walls

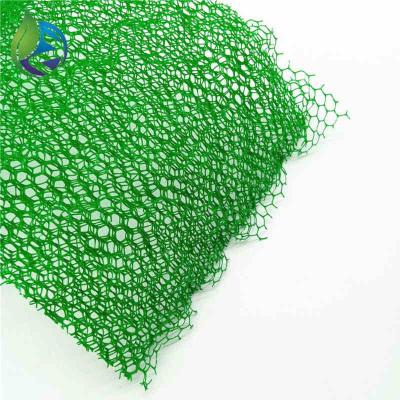

Steel-plastic geogrids are highly effective in reinforcing retaining walls, particularly in areas where soil pressure is high. The geogrids help to distribute the load and prevent the wall from collapsing or shifting over time. They are especially useful in the construction of gravity and reinforced soil retaining walls, where they provide additional support and stability.Slope Stabilization

One of the most common applications for high-quality steel-plastic geogrids is in slope stabilization. These geogrids are used to reinforce steep slopes, preventing soil erosion, landslides, and shifting. By securing the soil in place, they help maintain the stability of hillsides, embankments, and other elevated surfaces, reducing the risk of costly and dangerous landslides.Landfills and Waste Management

Steel-plastic geogrids are also used in the construction of landfill bases and waste management facilities. The geogrids help to stabilize the ground, improve drainage, and prevent subsidence or deformation under the weight of accumulated waste. Their corrosion resistance ensures they perform well in environments exposed to harsh chemicals or leachate.Airport and Runway Construction

The high tensile strength and durability of steel-plastic geogrids make them ideal for use in airport and runway construction. They are used to reinforce the subgrade and base layers of runways, ensuring that the surface remains stable and resilient under the weight of airplanes and heavy machinery. The geogrids also help to prevent cracking and shifting, which can compromise the safety and performance of the runway.