Polypropylene Fibre

Precast Concrete and Shotcrete Reinforcement with Polypropylene Mesh Fiber represent innovative solutions in the field of construction materials. Precast Concrete, also known as prefabricated concrete, is produced in a controlled environment before being transported to the construction site for installation. This method allows for more precise manufacturing, faster construction, and improved quality control. On the other hand, Shotcrete, which is pneumatically projected concrete at high velocity onto a surface, has found applications in tunnel linings, slope stabilization, and other structures. To further enhance the performance of Shotcrete, Polypropylene Mesh Fiber reinforcement is often utilized. Polypropylene fibers, known for their lightweight, high tensile strength, and corrosion resistance, are incorporated into Shotcrete mixtures to improve its crack resistance, durability, and overall structural integrity. This combination of Precast Concrete and Shotcrete Reinforcement with Polypropylene Mesh Fiber offers significant advantages in terms of efficiency, durability, and sustainability in modern construction projects.

In modern construction, durability, efficiency, and cost-effectiveness are not just desired—they are essential. That’s where Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber comes into play. Engineered for strength, flexibility, and long-term performance, this innovative fiber solution is transforming how concrete structures are built and reinforced.

Whether you're working on precast elements, tunnel linings, mine support, or shotcrete applications, integrating Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber ensures stronger, more crack-resistant structures at a fraction of the cost of traditional reinforcement methods.

What is Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber?

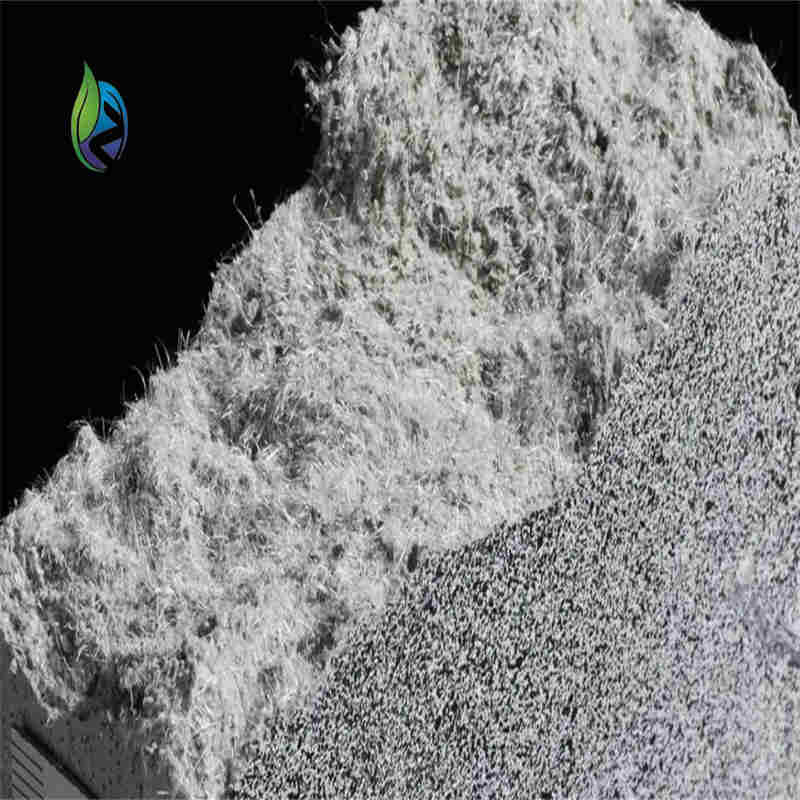

Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber is a high-strength, non-corrosive synthetic fiber made from 100% virgin polypropylene. It's specifically designed to be mixed directly into concrete or shotcrete to enhance tensile strength, control cracking, and improve impact resistance.

Unlike steel mesh or rebar, polypropylene mesh fiber is lightweight, corrosion-proof, and easy to distribute uniformly throughout the concrete matrix. This ensures consistent performance and eliminates the need for costly labor-intensive reinforcement placement.

Key Benefits of Using Polypropylene Mesh Fiber

✅ Crack Control & Shrinkage Reduction

The primary function of Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber is to minimize plastic shrinkage and early-age cracking—critical in shotcrete, tunnel, and precast applications.

✅ Enhanced Flexural Strength

The addition of mesh fibers increases post-crack behavior, improving ductility and toughness. This means greater load-bearing capacity and improved seismic performance.

✅ Corrosion Resistance

Unlike traditional steel reinforcement, polypropylene mesh fiber is completely resistant to corrosion, alkalis, and chemicals—ideal for high-humidity or aggressive environments.

✅ Time & Labor Savings

No need for cutting, tying, or placing steel mesh. Simply mix the polypropylene mesh fiber directly into the batch and pour. Faster, easier, and safer.

✅ Lightweight & Non-Conductive

Perfect for infrastructure requiring electrical insulation or low magnetic permeability—such as railway tunnels, utility shafts, and data centers.

Applications of Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber

Precast Concrete Panels & Pipes

Enhances tensile strength and ensures dimensional stability.Shotcrete in Tunnels & Underground Mining

Provides uniform reinforcement in sprayed concrete applications, reducing rebound and improving adhesion.Industrial Floors & Pavements

Improves durability, reduces joint maintenance, and prevents early cracking.Dams, Reservoirs, and Water Retaining Structures

Non-corrosive and water-resistant reinforcement for long-term structural integrity.Seismic-Resistant Construction

Boosts post-crack energy absorption for earthquake-prone zones.

Technical Specifications

Material: 100% Virgin Polypropylene

Form: Mesh Fiber / Net-like Structure

Length: 20–40mm (customizable)

Density: ~0.91g/cm³

Tensile Strength: >450 MPa

Melting Point: ~165°C

Dosage: Typically 0.9–1.8 kg/m³ (depending on application)

The optimized mesh geometry allows for better dispersion within the concrete mix, preventing fiber balling and ensuring uniform reinforcement.

Why Choose Our Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber?

?️ Proven Performance: Extensively used in global infrastructure, from subway tunnels to nuclear power plants.

? Eco-Friendly: Reduces carbon footprint by eliminating steel and lowering maintenance.

? Flexible Supply: Custom sizing, private labeling, and international shipping available.

? Expert Support: Our team offers on-site training, mix design consultation, and application guidance.

Invest in Performance. Build with Confidence.

When you choose Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber, you're not just buying a material—you’re upgrading your project’s structural performance, lifespan, and efficiency.

Imagine concrete that resists cracking, requires less maintenance, and is quicker to install—all while reducing costs. That’s the power of polypropylene mesh fiber.

Ready to Reinforce Smarter?

Make your next construction project stronger, safer, and more efficient with Precast Concrete and Shotcrete Reinforcement Polypropylene Mesh Fiber. Contact us today for samples, technical data sheets, or bulk pricing.

Don’t just pour concrete—reinforce it intelligently.