Polypropylene Fibers for Concrete

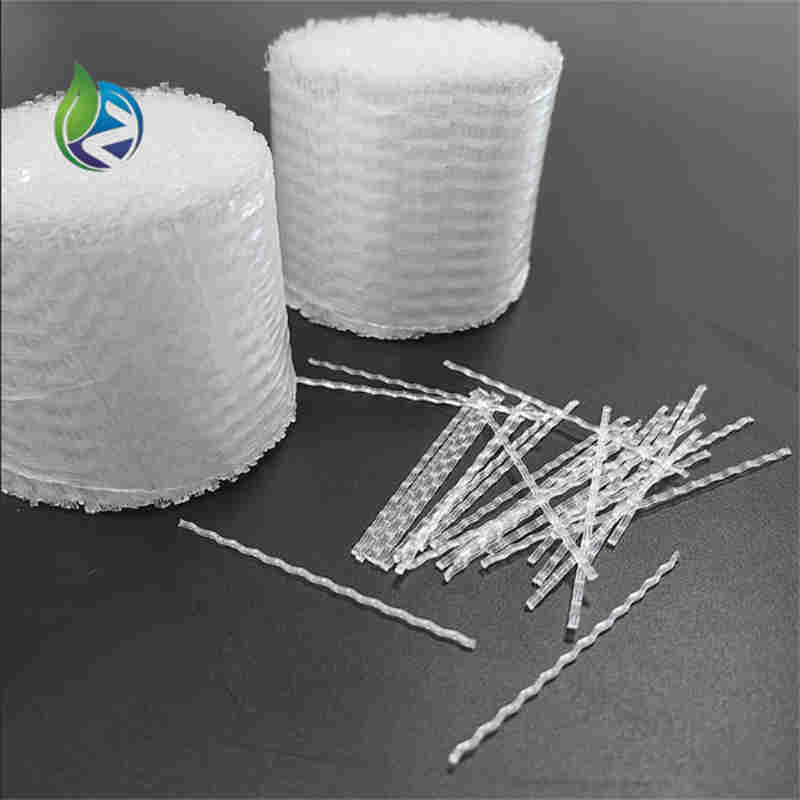

Cracking resistance of surface 100% virgin PP fiber ,also known as monofilament polypropylene fibers, used to enhance the strength of cement.

The application of these fibers in concrete is primarily aimed at improving its mechanical properties and durability. They work by reducing the formation and propagation of cracks in concrete, thereby increasing its strength and durability. When concrete is subjected to external stresses, these fibers can bear part of the tensile stress, preventing the generation of cracks or limiting their expansion.

The addition of polypropylene microfibers can also improve the concrete's resistance to impact, abrasion, and freeze-thaw cycles. Additionally, since polypropylene is a recyclable material, the use of polypropylene microfibers aligns with environmental protection requirements.

In practical applications, polypropylene microfibers are typically added to concrete at a specific dosage (calculated by volume or weight) and evenly dispersed during the mixing process. This ensures that the fibers achieve the best reinforcing effect in the concrete.

In modern construction, surface durability and long-term structural integrity are essential—especially in applications exposed to environmental stress, drying shrinkage, and thermal movement. That’s why more engineers and contractors are turning to Cracking Resistance of Surface 100% Virgin PP Fiber as a breakthrough solution for concrete and mortar reinforcement.

The Cracking Resistance of Surface 100% Virgin PP Fiber delivers superior performance by preventing early-age cracks, increasing toughness, and enhancing surface stability. Whether you're working on slabs, pavements, precast panels, or industrial floors, this fiber technology adds an advanced layer of protection—directly in the concrete mix.

What is 100% Virgin PP Fiber?

100% Virgin PP Fiber refers to polypropylene (PP) fibers made from high-purity raw material—never recycled—ensuring maximum tensile strength, high chemical stability, and long-term performance. These monofilament or fibrillated fibers are specifically engineered to distribute evenly throughout the concrete matrix, offering exceptional cracking resistance of surface structures.

Key Benefits: Cracking Resistance of Surface 100% Virgin PP Fiber

✅ Controls Plastic Shrinkage Cracking

The primary advantage of using 100% Virgin PP Fiber is its ability to minimize surface cracking caused by plastic shrinkage. As concrete cures, it loses water rapidly—leading to shrinkage stress. PP fibers create a multidirectional reinforcement network that resists these forces.

✅ Increases Impact and Abrasion Resistance

The cracking resistance of surface 100% virgin PP fiber significantly boosts concrete’s resistance to external mechanical impacts, foot traffic, machinery, and wear—making it perfect for industrial floors, driveways, and parking decks.

✅ No Corrosion Risk

Unlike steel mesh or wire reinforcement, 100% Virgin PP Fiber is non-corrosive. It doesn't rust, degrade in chemical environments, or weaken over time—ideal for marine, coastal, or chemically aggressive conditions.

✅ Enhances Surface Quality

Smooth, crack-free surfaces not only look better but also extend the service life of the structure. With cracking resistance of surface 100% virgin PP fiber, you're ensuring structural performance from the very first layer.

✅ Fast, Cost-Effective Integration

No need for extra tools or installation time—simply add PP fiber directly into the concrete or mortar mix. Its lightweight, tangle-free properties ensure even distribution and excellent workability.

Applications of 100% Virgin PP Fiber for Surface Cracking Resistance

Warehouse and Factory Floors

Airport Runways and Road Pavements

Residential Driveways and Sidewalks

Precast Concrete Products

Water Tanks and Dams

Tunnels and Underground Structures

The cracking resistance of surface 100% virgin PP fiber makes it suitable for both new construction and repairs where surface longevity is a top priority.

Technical Specifications

| Property | Specification |

|---|---|

| Material | 100% Virgin Polypropylene |

| Tensile Strength | ≥ 400 MPa |

| Fiber Length | 6 mm – 19 mm (customizable) |

| Density | 0.91 g/cm³ |

| Melting Point | 160–170°C |

| Acid & Alkali Resistance | Excellent |

| Dosage | 0.9 – 1.8 kg/m³ (application-specific) |

These specifications make 100% Virgin PP Fiber one of the most reliable solutions for surface cracking resistance across demanding construction environments.

Why Choose Our 100% Virgin PP Fiber?

? Purity & Consistency

Made from virgin raw materials, not recycled polymers—ensuring consistent fiber performance and surface results.

? Eco-Friendly Alternative to Steel

Lightweight, non-corrosive, and energy-efficient in production—offering a greener way to reinforce concrete.

? Global Supply Chain & Custom Packaging

We ship worldwide, offer OEM packaging, and provide on-site support for integration.

? Proven ROI for Contractors

Reduce repairs, callbacks, and surface defects—enhancing client satisfaction and cost-efficiency.

The Smart Way to Reinforce Concrete: Cracking Resistance of Surface 100% Virgin PP Fiber

The construction industry is shifting toward smarter, safer, and more sustainable reinforcement solutions—and the cracking resistance of surface 100% virgin PP fiber leads the way. Whether you’re working on infrastructure, commercial, or residential projects, investing in polypropylene fiber ensures superior durability, lower maintenance, and peace of mind.

Don't let surface cracks compromise your reputation or project budget. Choose cracking resistance of surface 100% virgin PP fiber—where technology meets reliability.