PP Fiber for Concrete

Manufacturing Process

Polymer Pellet Feeding: Virgin polypropylene pellets fed into twin-screw extruders

Melt Extrusion: Controlled barrel temperatures between 180–230°C

Spinneret Drawing: Fibers drawn through micro-dies to required diameter

Stretching and Orientation: Molecular chain alignment to increase tensile strength

Heat Setting: Thermal stabilization to lock internal structure

Cutting Process: Precision cutting to specified fiber lengths

Surface Treatment: Optional embossing or fibrillation

Final Inspection: Length, tensile, and dispersion performance testing

Product Definition

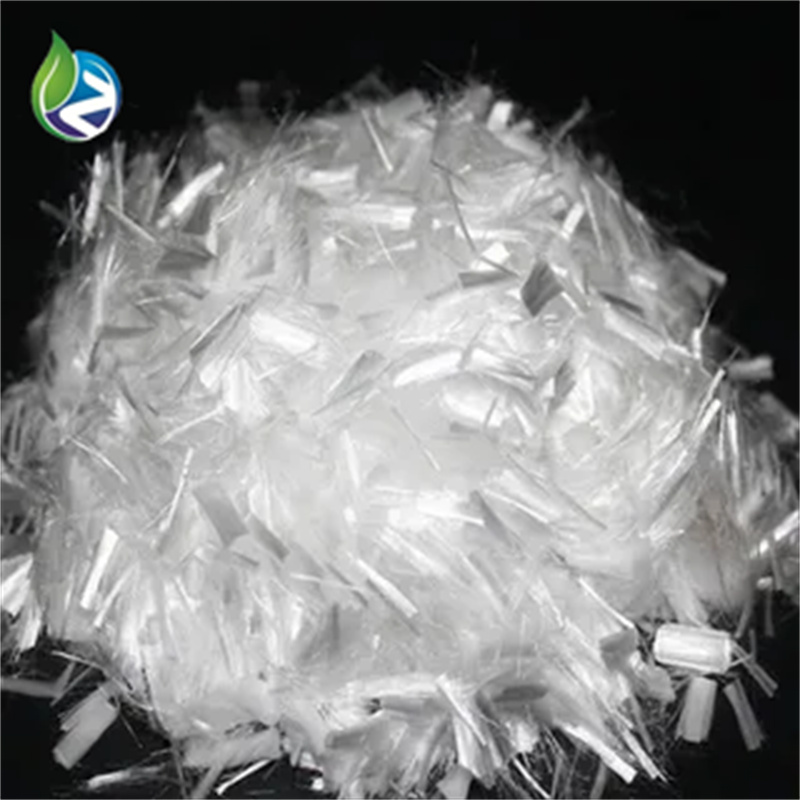

PP Fiber for Concrete is a synthetic micro- or macro-reinforcement material produced from polypropylene polymer and distributed within cementitious matrices to control plastic shrinkage cracking, improve impact resistance, and enhance post-crack toughness without altering core mix design.

Technical Parameters and Specifications

Actual engineering-grade specifications for PP Fiber for Concrete used in structural and non-structural applications:

Material: 100% Virgin Polypropylene

Fiber Type: Monofilament / Fibrillated

Fiber Length: 6 mm, 12 mm, 18 mm, 24 mm, 40 mm

Equivalent Diameter: 18–45 μm (monofilament)

Tensile Strength: ≥ 350 MPa

Elastic Modulus: 3.0–5.0 GPa

Density: 0.91 g/cm³

Melting Point: 160–170°C

Recommended Dosage: 0.6–3.0 kg/m³ of concrete

Alkali Resistance: Excellent (no degradation in high-pH cement matrix)

Structure and Material Composition

Typical structural forms of PP Fiber for Concrete:

Monofilament Fibers: Smooth, straight micro-reinforcement strands

Fibrillated Network Fibers: Mesh-like structure improving mechanical interlock

Surface-Modified Fibers: Plasma or embossed surface to enhance bonding

Additive System: Antistatic and dispersion-control additives

Manufacturing Process

Polymer Pellet Feeding: Virgin polypropylene pellets fed into twin-screw extruders

Melt Extrusion: Controlled barrel temperatures between 180–230°C

Spinneret Drawing: Fibers drawn through micro-dies to required diameter

Stretching and Orientation: Molecular chain alignment to increase tensile strength

Heat Setting: Thermal stabilization to lock internal structure

Cutting Process: Precision cutting to specified fiber lengths

Surface Treatment: Optional embossing or fibrillation

Final Inspection: Length, tensile, and dispersion performance testing

Industry Comparison

| Reinforcement Type | Crack Control | Corrosion Risk | Mix Workability Impact | Lifecycle Maintenance |

|---|---|---|---|---|

| PP Fiber for Concrete | High | None | Low | Low |

| Steel Fiber | Very High | High | Medium | Medium |

| Glass Fiber | Medium | None | Medium | Medium |

Application Scenarios

Industrial floor slabs and warehouses

Precast concrete elements and pipes

Shotcrete linings and tunnel supports

Bridge deck overlays and repair mortars

Water-retaining structures and tanks

Core Pain Points and Engineering Solutions

Plastic Shrinkage Cracking: Fibers form a three-dimensional restraint network

Surface Microcracks under Drying: Even fiber dispersion limits crack propagation

Low Impact Resistance: Fibers improve energy absorption capacity of concrete

Corrosion of Traditional Reinforcement: Polypropylene eliminates oxidation risks

Risk Warnings and Mitigation Recommendations

Risk: Fiber balling during mixing

Mitigation: Pre-blend fibers with fine aggregates before water additionRisk: Reduced slump

Mitigation: Adjust superplasticizer dosage based on trial batchesRisk: Uneven dispersion in high-strength mixes

Mitigation: Extend mixing time by 30–60 secondsRisk: Incorrect dosage

Mitigation: Use calibrated weight-based dosing equipment

Procurement and Selection Guide

Define project performance targets for crack control

Select fiber type based on concrete grade and application

Determine optimal fiber length through laboratory trial mixes

Verify tensile strength certificates and material traceability

Request alkali resistance and durability test reports

Evaluate supplier production capacity and quality control system

Confirm packaging method for bulk handling efficiency

Engineering Application Case

In a logistics warehouse floor project covering 18,000 m², PP Fiber for Concrete was used at a dosage of 1.2 kg/m³ in C30/37 concrete. The fiber-reinforced slab achieved controlled crack widths and passed post-construction flatness and abrasion resistance inspections, reducing long-term maintenance requirements.

FAQ

Q1: Can PP fibers replace steel rebar? A: No, they are complementary crack control reinforcement.

Q2: Do fibers affect setting time? A: No significant impact when properly dosed.

Q3: Suitable for high-temperature concrete? A: Yes, within typical construction temperature ranges.

Q4: Does it improve freeze-thaw durability? A: Indirectly, by limiting crack formation.

Q5: Can it be used in precast plants? A: Yes, with verified mixing control.

Q6: Storage requirements? A: Dry, shaded, and well-ventilated conditions.

Q7: Shelf life? A: Up to 24 months in sealed packaging.

Q8: Does it affect pumpability? A: Minimal effect with proper grading.

Q9: Is it compatible with fly ash or slag cement? A: Yes.

Q10: Typical quality inspection on site? A: Visual dispersion and slump verification.

Call to Action

For formal quotation, technical datasheets, or project-specific samples of PP Fiber for Concrete, submit detailed project information to the technical procurement department.

E-E-A-T Author Credentials

This article is prepared by a civil materials engineer with over 15 years of experience in concrete performance optimization, fiber reinforcement systems, and large-scale commercial and infrastructure construction projects.