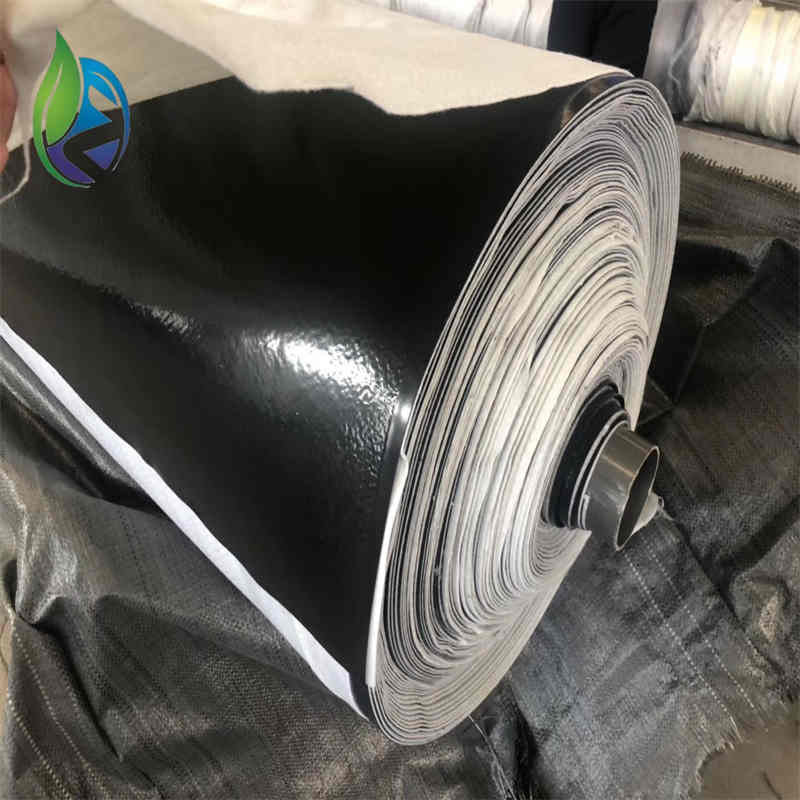

Geotextile Composite Geomembrane

As a new type of geomembrane, composite geomembrane has multiple excellent properties. Its primary role is waterproof and impermeable, which can effectively prevent water penetration and protect soil and underground structures from water erosion. At the same time, the composite geomembrane also has good isolation performance, which can isolate different soil layers and prevent the interaction between soil layers. In addition, it also has the characteristics of anti-aging, corrosion resistance, wear resistance, and can maintain stable performance in harsh environments for a long time.

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

Geotextile Composite Geomembrane: Advanced Waterproofing and Reinforcement Solution

Geotextile composite geomembrane is an engineered geosynthetic material designed to combine the strengths of geotextiles and geomembranes. By bonding one or more layers of geotextile fabric with high-performance HDPE, LDPE, or PVC geomembrane sheets, the geotextile composite geomembrane delivers superior waterproofing, durability, and soil interaction characteristics. It is widely used in civil engineering, environmental protection, mining, and water conservation projects.

What Is a Geotextile Composite Geomembrane?

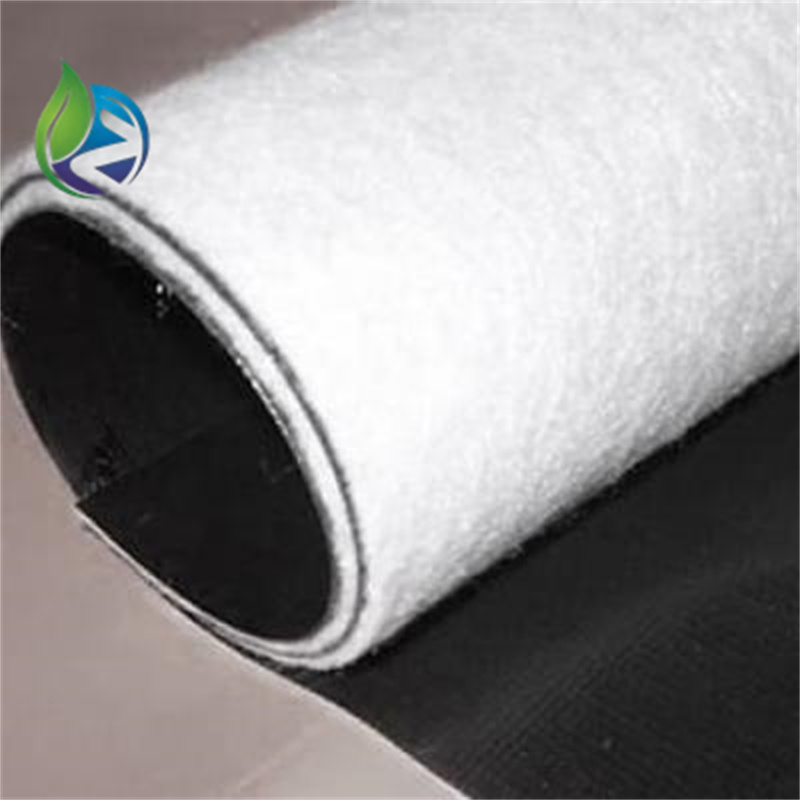

A geotextile composite geomembrane integrates a geotextile (nonwoven or woven) with a geomembrane layer to form a robust barrier against seepage and environmental degradation. The geotextile enhances puncture resistance and mechanical bonding with soil, while the geomembrane provides an impermeable layer to block liquid or gas migration. This dual-function product is ideal for applications requiring both filtration and containment.

Key Advantages of Geotextile Composite Geomembrane

Superior Seepage Control: The geomembrane layer ensures total impermeability, making the geotextile composite geomembrane ideal for lining ponds, canals, and landfills.

High Tensile Strength: Reinforced by the geotextile, this composite material resists tearing and elongation, even under high stress.

Enhanced Puncture and Abrasion Resistance: The geotextile layer protects the geomembrane from damage during installation and throughout its service life.

Chemical and UV Resistance: The geotextile composite geomembrane resists degradation from chemicals, acids, and prolonged UV exposure.

Excellent Soil Compatibility: The geotextile enables better anchoring and friction with soil or other geotechnical surfaces.

Applications of Geotextile Composite Geomembrane

The geotextile composite geomembrane is a preferred solution in the following areas:

Landfill Lining and Cover Systems: Prevents leachate from contaminating soil and groundwater.

Mining Projects: Used for heap leach pads, tailings ponds, and process water containment.

Aquaculture and Agriculture: Ideal for fish ponds, irrigation canals, and agricultural reservoirs.

Tunnel and Underground Structures: Waterproofs concrete and reduces infiltration risks.

Wastewater Treatment Plants: Ensures containment of hazardous and non-hazardous fluids.

Embankments and Dams: Protects structural integrity while preventing seepage.

In all these environments, the geotextile composite geomembrane offers a long-term solution to meet stringent environmental and structural requirements.

Geotextile Composite Geomembrane Technical Specifications

| Property | Typical Value Range |

|---|---|

| Geomembrane Material | HDPE / LDPE / PVC |

| Geotextile Type | Nonwoven (PET or PP) |

| Thickness | 0.5mm to 2.5mm |

| Bonding Method | Heat Lamination or Glue |

| Puncture Resistance | ≥ 1.2 kN |

| Tensile Strength | ≥ 15 kN/m |

| Elongation at Break | ≥ 300% |

| Width | 1–6 meters |

| Length per Roll | Customizable (usually 50–100m) |

These specifications may vary based on project requirements and manufacturing standards.

Why Choose Geotextile Composite Geomembrane?

Choosing a geotextile composite geomembrane gives project engineers and environmental managers confidence in long-term performance. It ensures:

Efficient Construction: Easy deployment reduces installation time and labor costs.

Reliable Sealing: Offers consistent impermeability even under fluctuating load and temperature conditions.

Environmental Safety: Prevents contamination of groundwater and surrounding ecosystems.

Cost Savings: Reduces the need for multi-layered systems by combining functions into one material.

Longevity: Engineered to last over decades in demanding outdoor conditions.

Installation Tips for Geotextile Composite Geomembrane

Surface Preparation: Ensure the subgrade is smooth, compacted, and free of sharp objects.

Unrolling and Positioning: Unroll the geotextile composite geomembrane gently to avoid creasing or tearing.

Seaming and Bonding: Use hot wedge welding or extrusion welding for the geomembrane, and ensure overlap of geotextile layers for continuity.

Anchoring and Protection: Secure the edges in anchor trenches and cover with protective soil or sand layers.

Inspection and Testing: Perform visual and non-destructive tests on all seams and surfaces before backfilling.

Final Thoughts

The geotextile composite geomembrane is a game-changing material for industries that demand high-performance containment, reinforcement, and filtration. Its hybrid nature delivers the best of both worlds—durable waterproofing from the geomembrane and mechanical support from the geotextile. Whether you are working on a landfill, reservoir, or mining site, investing in geotextile composite geomembrane technology ensures long-term environmental compliance, structural safety, and cost-efficiency.