Waterproof Composite Membrane for Dam

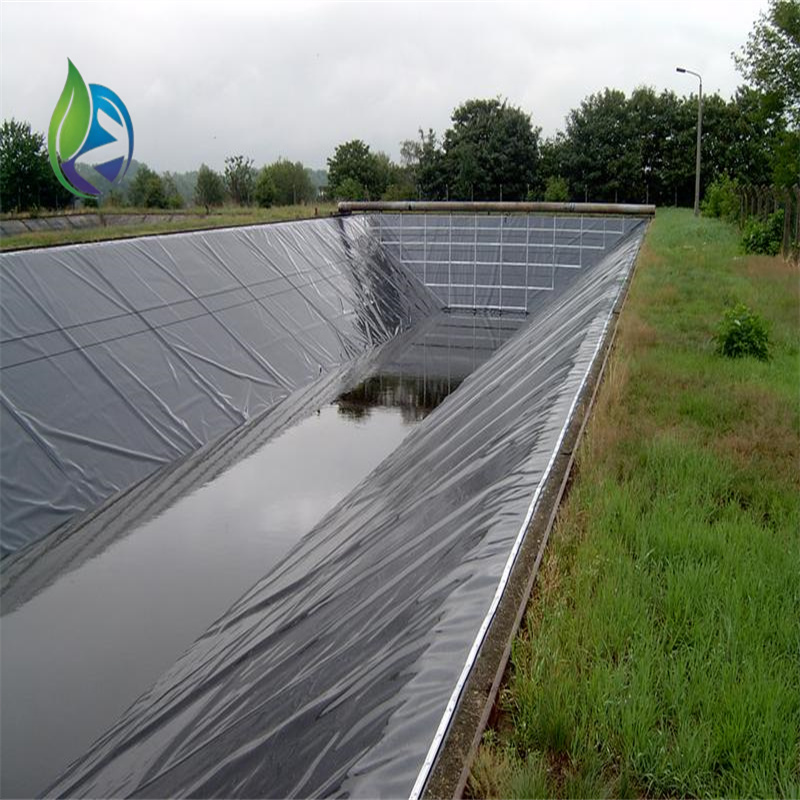

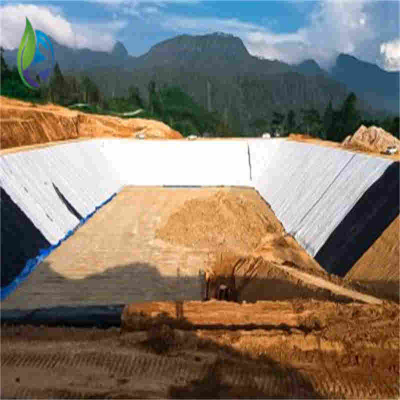

The waterproof composite membrane for dams is a versatile and innovative solution that not only provides exceptional waterproofing capabilities but also offers added benefits such as resistance to UV rays, chemicals, and punctures. This multi-layered membrane system is designed to withstand the harsh environmental conditions often present in dam settings, ensuring long-term protection and performance. The seamless installation of the composite membrane minimizes the risk of water infiltration and seepage, effectively preserving the structural integrity of the dam and preventing potential water damage.

In addition to its waterproofing properties, the composite membrane can also contribute to environmental sustainability by reducing water loss through seepage and enhancing the overall efficiency of dam operations. By incorporating this advanced membrane technology into dam construction and rehabilitation projects, engineers and stakeholders can enhance the resilience and longevity of dam structures while promoting sustainable water management practices.

In the world of dam construction and reinforcement, one material stands out for its durability, efficiency, and reliability—the waterproof composite membrane for dam. As water infrastructure faces growing environmental challenges, using the right waterproofing system has become more critical than ever.

So what makes the waterproof composite membrane for dam a game-changing solution in civil engineering? Let’s break it down.

What Is a Waterproof Composite Membrane for Dam?

A waterproof composite membrane for dam is a multi-layer barrier system typically made from geotextiles, high-density polyethylene (HDPE), and polymer coatings. These layers are bonded together to create a high-performance waterproofing membrane that can:

Prevent water seepage

Withstand hydrostatic pressure

Resist UV, chemical, and mechanical damage

Unlike traditional single-layer geomembranes, the composite design provides both sealing and reinforcement, offering double-layered protection for concrete and earth-fill dams.

6 Key Benefits of Waterproof Composite Membrane for Dam

Superior Waterproofing Performance

The composite structure ensures zero leakage even under extreme pressure. It keeps the dam’s foundation and core dry and stable.Outstanding Durability

These membranes are built to last 25–50 years, resisting punctures, cracking, and environmental aging.Adaptability to Harsh Conditions

Whether it’s extreme cold, heat, or chemical exposure from sediment and runoff, the waterproof composite membrane for dam stands strong.Easy On-Site Installation

Lightweight and rollable, the membrane can be applied quickly using mechanical or manual laying methods, even in complex terrain.Reduces Maintenance Costs

By minimizing seepage and structural wear, dams lined with composite membranes require fewer repairs over time.Eco-Friendly Material Options

Many modern composite membranes are manufactured using recyclable, non-toxic materials, meeting international environmental standards.

Real-World Applications of Waterproof Composite Membrane for Dam

Clay-core earth dams

Concrete-faced rockfill dams (CFRDs)

Spillways and water tunnels

Flood control and reservoir lining

Dam reinforcement and retrofitting

From new builds to renovation projects, the waterproof composite membrane for dam is now a standard material in hydraulic engineering.

Engineer Voices from the Field

? @HydroEngineer_Marko

“We used a waterproof composite membrane for a 36m high dam in Croatia. Even after two years of heavy rainfall and freeze-thaw cycles, no seepage has been detected. Excellent tensile strength and weldability!”

? @SiteManager_JulieY

“Quick to install and highly effective. The composite membrane for dams helped us avoid costly concrete reinforcements. It saved time and labor on-site.”

? @GreenWaterWorks

“Reliable performance, especially in steep-sided reservoirs. We’ve replaced older bitumen layers with these composite membranes and saw an immediate improvement in water retention.”

How It Compares: Composite vs Traditional Waterproofing

| Feature | Traditional Geomembrane | Waterproof Composite Membrane for Dam |

|---|---|---|

| Layers | Single | Multi-layer (geotextile + membrane) |

| Durability | Moderate | High |

| Puncture Resistance | Low | Excellent |

| UV/Chemical Resistance | Moderate | High |

| Installation Flexibility | Limited | Flexible, adaptable |

| Cost-Efficiency (Long-Term) | Low | High |

Frequently Asked Questions

Q1: How is the waterproof composite membrane for dam installed?

A: It’s typically unrolled across the dam surface and either heat-welded or joined using adhesive/seam tapes, depending on the membrane type.

Q2: Can it be used in retrofitting old dams?

A: Absolutely. It’s a great solution for upgrading leaking or unstable dam structures.

Q3: What thickness is ideal for a dam membrane?

A: Usually 1.5mm to 3.0mm, depending on design pressure and base material.

Buyer’s Guide: Choosing the Right Waterproof Composite Membrane for Dam

When purchasing a waterproof composite membrane for dam, consider:

Tensile strength and elongation rate

Weather and chemical resistance certifications

Welding compatibility and seam strength

Custom width and roll length availability

Factory warranty and technical support

Avoid low-cost generic alternatives that may lack proper bonding between layers. A trusted supplier will offer technical consultation, installation guides, and quality assurance documents.

Final Thoughts

The waterproof composite membrane for dam is more than just a construction material—it's a safeguard for lives, ecosystems, and investments. With rising global attention on water conservation and infrastructure resilience, using composite membranes ensures your dam meets both engineering and environmental standards.

Whether you're managing a new hydropower development or restoring an aging flood control structure, this membrane is a smart, sustainable, and cost-effective solution.

Benefits of Using Waterproof Composite Membrane for Dams

Prevents Water Seepage – Maintains water retention efficiency, reducing loss through dam structures.

Enhances Dam Stability – Provides structural reinforcement, preventing erosion and soil displacement.

Reduces Maintenance Costs – Minimizes the need for frequent repairs and reduces long-term operational expenses.

Protects Against Environmental Damage – Prevents chemical contamination, soil erosion, and degradation of the dam foundation.

Improves Water Quality – Acts as a protective barrier, preventing contaminants from entering water sources.

Sustainable and Eco-Friendly – Reduces the environmental impact of dam construction by minimizing material waste and water loss.