Short Fiber Needle Punched Geotextile

2.PP or PET staple fiber as the main raw material, using non-woven process production.

3.Corrosion resistance, acid and alkali resistance, oxidation resistance.

4.Good water permeability, filtration and isolation performance.

Looking for a reliable and durable geotextile material that combines performance with cost-efficiency?

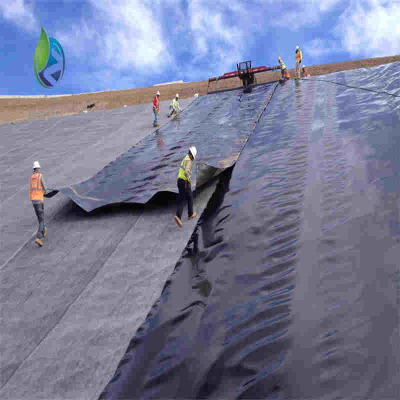

Short fiber needle punched geotextile might just be the solution your project needs. Whether you're in road construction, landfill engineering, or erosion control, this versatile fabric plays a vital role in modern infrastructure. But what makes it stand out?

In this guide, we’ll walk you through everything you need to know — from how it’s made to how it performs on-site. Let’s explore why short fiber needle punched geotextile is quickly becoming a go-to solution for engineers and contractors alike.

What Is Short Fiber Needle Punched Geotextile?

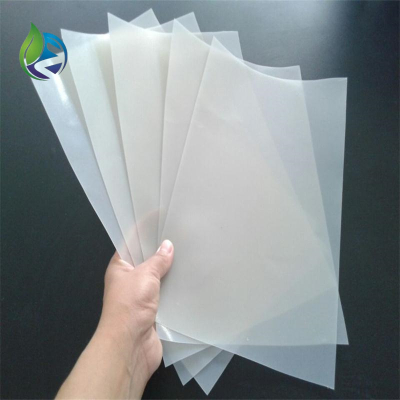

Short fiber needle punched geotextile is a non-woven fabric made by mechanically bonding synthetic fibers (typically polyester or polypropylene) through a process called needle punching. This technique interlocks the fibers, creating a strong, permeable material that serves multiple engineering functions like filtration, separation, protection, and reinforcement.

? Fun Fact: Unlike woven geotextiles, needle punched variants are more flexible and offer superior water permeability — making them ideal for drainage-heavy environments.

Key Properties That Make It a Smart Choice

Let’s take a closer look at why short fiber needle punched geotextile stands out in practical applications:

High Tensile Strength: Offers excellent durability even under heavy load or pressure.

Superior Filtration: Allows water to pass through while trapping soil particles — ideal for erosion control.

Chemical Resistance: Resists acids, alkalis, and other aggressive agents in soil.

UV Stability: Maintains structural integrity when exposed to sunlight for long durations.

Lightweight & Easy to Install: Saves time and labor costs during deployment.

Where Is Short Fiber Needle Punched Geotextile Used?

This geotextile type is widely used in:

Road Construction — to reinforce the base and prevent rutting.

Railway Projects — to separate soil layers and improve load distribution.

Landfills & Drainage Systems — for filtration and leachate collection.

Riverbanks & Coastal Areas — to reduce soil erosion and improve slope stability.

Agriculture & Landscaping — to prevent weed growth while maintaining moisture control.

How to Choose the Right Geotextile for Your Project

When selecting a short fiber needle punched geotextile, consider these factors:

GSM (Grams per Square Meter): Common grades range from 100g to 600g. Higher GSM offers better durability.

Tensile Strength & Elongation: Make sure the fabric can handle stress without tearing.

Permeability Rate: Crucial for drainage-related applications.

Project Scope & Budget: Match the performance grade with your expected load and environmental conditions.

?♂️ Pro Tip: Always consult with a geotechnical engineer or supplier to get precise specs based on your soil tests and design goals.

User Reviews & Testimonials

?️ “We’ve used short fiber needle punched geotextile for a highway project last year, and it performed flawlessly. Easy to install, and no signs of settlement or soil migration even after heavy rainfall.”

— James L., Site Manager, TX

?️ “Great product for the price. We used it in our agricultural fields for weed suppression and drainage — works far better than plastic mulch.”

— Anita W., Farm Owner, CA

FAQ: Everything You’re Wondering About

Q1: Is short fiber needle punched geotextile biodegradable?

A: No, it’s made from synthetic materials like polyester or polypropylene. However, it is chemically inert and environmentally safe.

Q2: Can I use this for home landscaping?

A: Absolutely! It’s ideal for garden beds, walkways, or as a base layer beneath gravel and mulch.

Q3: What’s the difference between needle punched and heat bonded geotextile?

A: Needle punched geotextiles are mechanically interlocked, providing better strength and permeability. Heat bonded types are stiffer and better for smoother finishes but usually less porous.

Where to Buy Short Fiber Needle Punched Geotextile?

Looking for high-quality short fiber needle punched geotextile at competitive prices? Choose suppliers with:

Proven ISO certifications

Clear product specifications (GSM, permeability, strength)

Positive customer reviews

Responsive technical support

? Many professionals recommend starting with bulk suppliers or direct manufacturers to get better pricing and guaranteed quality.

Final Thoughts:

Short fiber needle punched geotextile is more than just a fabric — it’s a foundational material in modern civil engineering. Its strength, permeability, and versatility make it indispensable for any project demanding long-term durability and efficient water management.

Have questions or need help choosing the right type? Drop your thoughts in the comments — we love helping fellow builders and engineers make informed decisions!