EVA Geomembrane

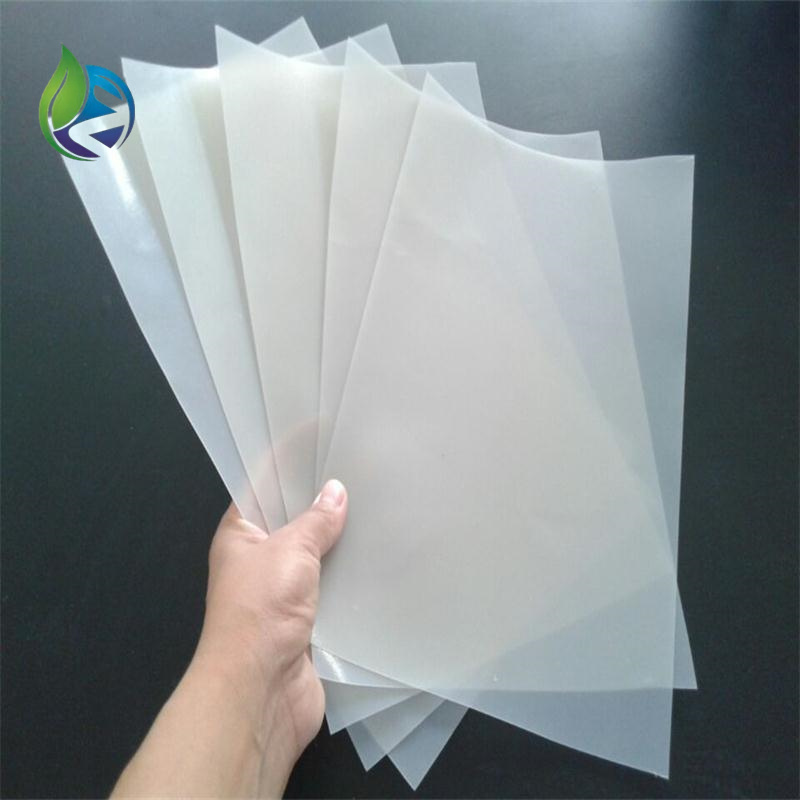

EVA geomembrane is a highly specialized and advanced material that has revolutionized waterproofing and seepage control in various industries. It is a composite geomembrane, a layer of flexible, durable material used in geotechnical engineering, specifically designed to prevent the passage of water or other liquids. The core of EVA geomembrane is Ethylene Vinyl Acetate (EVA) plastic, a copolymer of ethylene and vinyl acetate that offers exceptional properties suitable for these applications.

EVA geomembrane's unique blend of properties makes it an ideal choice for demanding waterproofing projects. Its primary characteristic is its remarkable impermeability, ensuring that water and other fluids are effectively contained or excluded as required. This is crucial in water conservancy projects like reservoirs, dams, and canals, where the integrity of the water barrier is paramount. Additionally, EVA geomembrane's resistance to chemical attack ensures that it remains functional even in harsh environments with exposure to acids, alkalis, and other corrosive substances.

EVA Geomembrane for Tunnel Composite Lining: Flexible and Durable Waterproofing Solution

EVA geomembrane for tunnel composite lining is a high-performance waterproofing material widely used in modern tunnel engineering. Made from ethylene-vinyl acetate (EVA) resin, this geomembrane provides excellent flexibility, elongation, and chemical resistance. Whether used in rail, highway, or urban subway tunnels, EVA geomembrane for tunnel composite lining ensures reliable moisture protection and long-term structural integrity.

What Is EVA Geomembrane for Tunnel Composite Lining?

EVA geomembrane for tunnel composite lining is a thermoplastic sheet specifically designed for tunnel waterproofing systems. It is typically used in conjunction with non-woven geotextiles, forming a composite lining structure that provides both water barrier functionality and mechanical protection. The main advantages of EVA geomembrane for tunnel composite lining include flexibility in low temperatures, superior puncture resistance, and long lifespan.

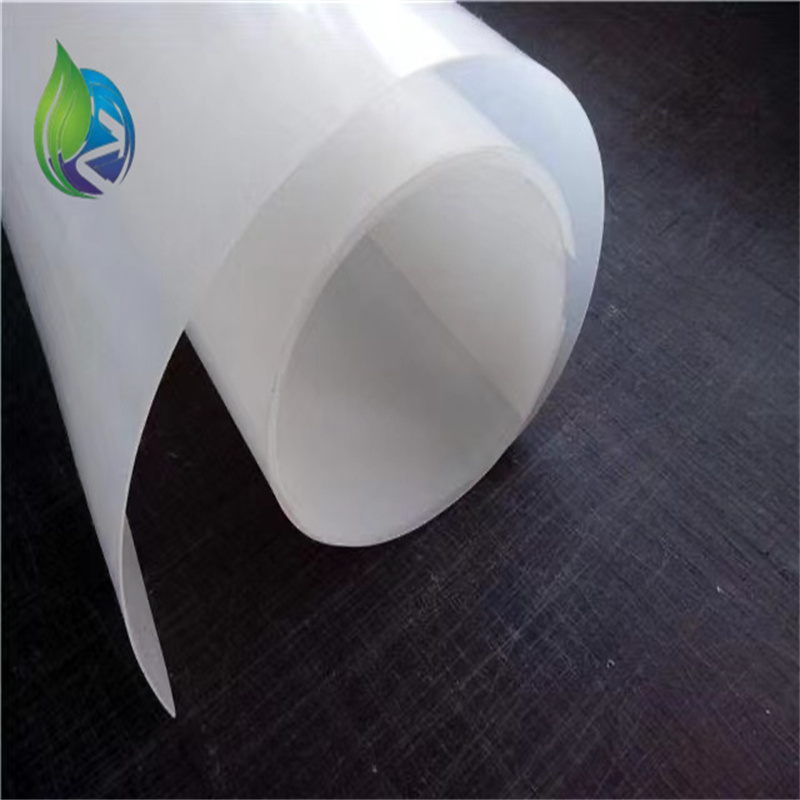

Compared to HDPE or PVC membranes, EVA geomembrane for tunnel composite lining performs better in curved tunnel profiles and high-deformation zones due to its outstanding elasticity and stress-crack resistance.

Key Features of EVA Geomembrane for Tunnel Composite Lining

High Flexibility and Elongation

EVA geomembrane for tunnel composite lining remains soft and flexible even at low temperatures, making it ideal for tunnels with complex geometries and settlement zones.Excellent Waterproofing Performance

With low water permeability, the EVA geomembrane for tunnel composite lining acts as a strong barrier against water ingress and hydrostatic pressure.Strong Bonding Ability

Compatible with spray-applied waterproofing and concrete structures, it ensures long-lasting adhesion within composite lining systems.UV and Chemical Resistance

EVA geomembrane for tunnel composite lining resists degradation from soil chemicals, groundwater, and light exposure, enhancing durability.Tear and Puncture Resistance

The material provides robust protection against mechanical stress during installation and operation.

Applications of EVA Geomembrane for Tunnel Composite Lining

The EVA geomembrane for tunnel composite lining is primarily used in:

Subway and Railway Tunnels

Offers continuous waterproofing protection for urban transport systems.Highway and Mountain Tunnels

Prevents groundwater seepage that can damage concrete structures and reduce safety.Hydraulic Tunnels and Drainage Galleries

Enhances structural reliability in water-conveying systems.Underground Parking and Utility Tunnels

Maintains dry conditions and protects electrical systems from moisture damage.

In each of these scenarios, the EVA geomembrane for tunnel composite lining plays a key role in improving tunnel durability, reducing maintenance costs, and ensuring long-term performance.

Installation of EVA Geomembrane for Tunnel Composite Lining

To achieve optimal results with EVA geomembrane for tunnel composite lining, follow industry-standard installation procedures:

Substrate Preparation

Clean and smooth the tunnel surface to eliminate sharp protrusions or debris.Geotextile Layer Placement

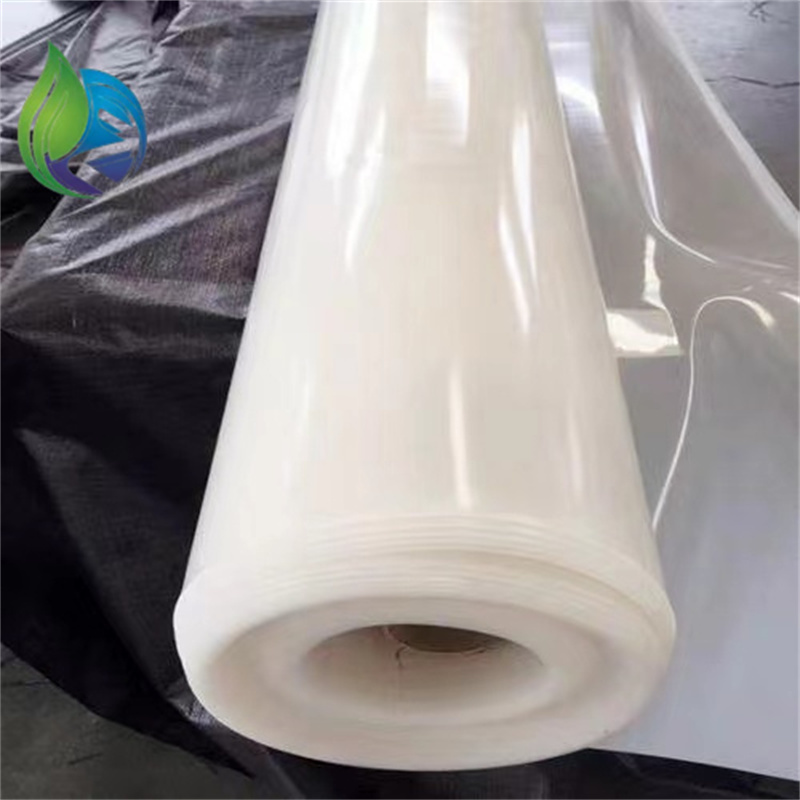

Lay non-woven geotextile as a cushioning layer to protect the EVA geomembrane.Membrane Deployment

Position the EVA geomembrane for tunnel composite lining evenly across the surface with appropriate overlaps.Seam Welding

Use hot wedge or extrusion welding to fuse the sheets and ensure continuous waterproof coverage.Post-Installation Testing

Conduct air pressure or spark testing to verify seam integrity and waterproofing performance.

Advantages of EVA Geomembrane for Tunnel Composite Lining

Ideal for high deformation zones and curved surfaces

Lightweight and easy to handle on-site

Compatible with both open-cut and NATM tunnel methods

Long service life (over 50 years under protected conditions)

Safe for use in sensitive environments (non-toxic and recyclable)

By using EVA geomembrane for tunnel composite lining, project engineers and contractors can enhance tunnel safety, prevent water-related damage, and ensure the infrastructure meets demanding performance standards.

Conclusion

As tunnel construction projects face increasing demands for durability, efficiency, and environmental performance, EVA geomembrane for tunnel composite lining stands out as the smart choice for reliable waterproofing. Its unmatched flexibility, chemical resistance, and ease of installation make it the preferred solution for both new constructions and rehabilitation works.

Choose EVA geomembrane for tunnel composite lining to build dry, strong, and future-proof underground structures.