HDPE Geomembrane for Industrial

Manufacturing Process

Engineering manufacturing steps for HDPE Geomembrane for Industrial production:

HDPE resin drying and gravimetric dosing

Flat die or blown film extrusion using high-output extruders

Precise thickness control through automatic scanning systems

Surface texturing by embossing rolls when required

Online spark testing for pinhole and defect detection

Controlled cooling and stress-relief annealing

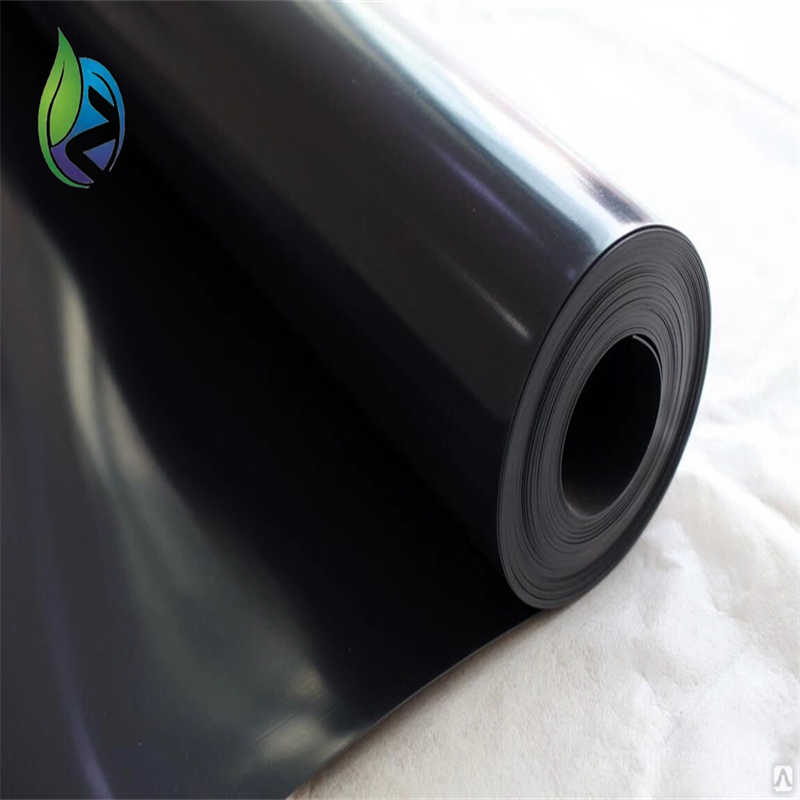

Roll winding, labeling, batch coding and palletized packaging

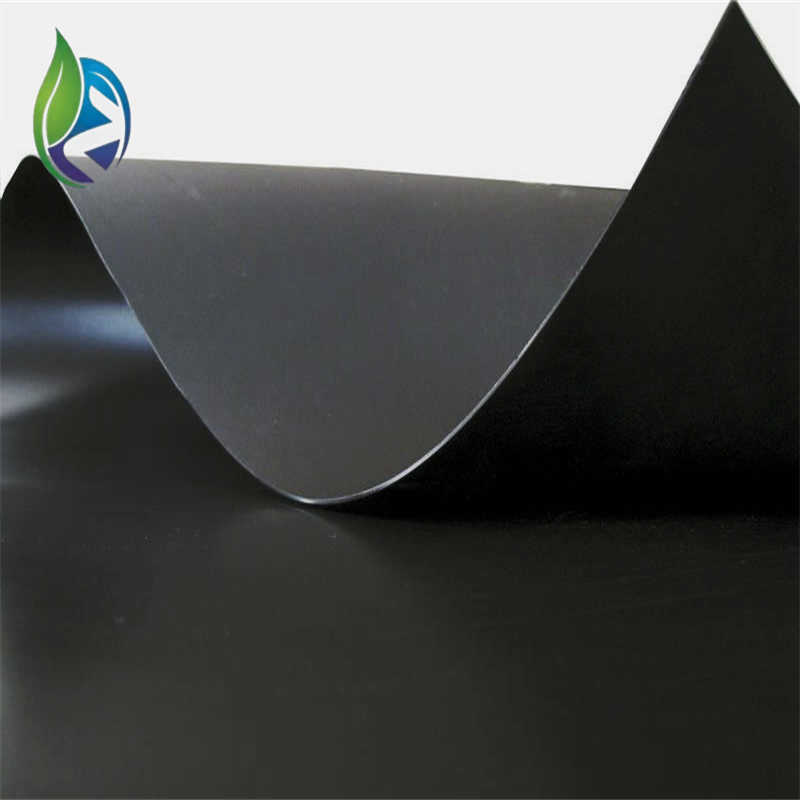

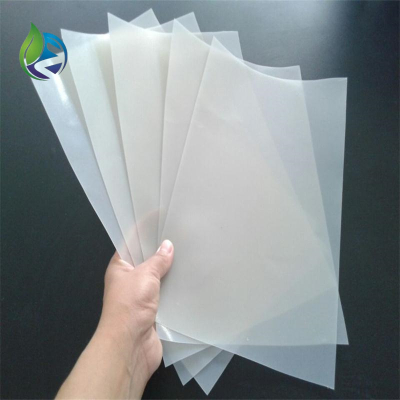

Product Definition

HDPE Geomembrane for Industrial is a high-density polyethylene impermeable liner engineered for containment, seepage control and chemical resistance in heavy-duty industrial environments, providing long-term barrier performance for hazardous liquids, process water and solid waste containment systems.

Technical Parameters and Specifications

Standard technical data for HDPE Geomembrane for Industrial applications:

Material: High-density polyethylene (HDPE)

Thickness range: 0.5 mm – 3.0 mm

Density: ≥ 0.940 g/cm³

Tensile strength at yield: ≥ 15 MPa

Tensile strength at break: ≥ 25 MPa

Elongation at break: ≥ 700%

Tear resistance: ≥ 120 N

Puncture resistance: ≥ 600 N

Carbon black content: 2.0% – 3.0%

Oxidative induction time (OIT): ≥ 100 min

Service temperature range: -40°C to +60°C

Structure and Material Composition

Typical structural design of HDPE Geomembrane for Industrial containment systems:

Single or double-layer smooth HDPE barrier sheet

Optional textured surface for enhanced interface friction

Core polymer layer with homogenous density distribution

Additive system:

Carbon black for UV stabilization

Antioxidants for thermal aging resistance

Processing aids for extrusion stability

Manufacturing Process

Engineering manufacturing steps for HDPE Geomembrane for Industrial production:

HDPE resin drying and gravimetric dosing

Flat die or blown film extrusion using high-output extruders

Precise thickness control through automatic scanning systems

Surface texturing by embossing rolls when required

Online spark testing for pinhole and defect detection

Controlled cooling and stress-relief annealing

Roll winding, labeling, batch coding and palletized packaging

Industry Comparison

| Material Type | Chemical Resistance | Mechanical Strength | Service Life | Industrial Suitability |

|---|---|---|---|---|

| HDPE Geomembrane | Very High | High | 30–50 Years | Excellent |

| LDPE Liner | Medium | Low | 15–25 Years | Limited |

| PVC Membrane | Medium | Medium | 20–30 Years | Moderate |

| EPDM Rubber Liner | High | Medium | 20–30 Years | Moderate |

Application Scenarios

HDPE Geomembrane for Industrial is specified by distributors and EPC contractors in:

Mining leach pads and tailings storage facilities

Chemical plant secondary containment ponds

Industrial wastewater treatment lagoons

Hazardous waste landfill liners

Power plant ash ponds and slurry containment areas

Key Pain Points and Solutions

Chemical leakage risk: High-density polymer matrix provides excellent chemical barrier.

Stress cracking failures: Optimized resin and OIT values improve long-term resistance.

Installation damage: High puncture resistance reduces handling and placement risks.

UV degradation: Carbon black stabilized formulation ensures outdoor durability.

Risk Warnings and Mitigation Recommendations

Avoid installation on sharp subgrade; use protective geotextile underlayment.

Control welding temperature and pressure to prevent weak seams.

Limit prolonged exposure before cover placement in extreme climates.

Verify chemical compatibility with stored media prior to final material selection.

Procurement and Selection Guide

Define containment type and expected chemical exposure profile.

Confirm required geomembrane thickness based on hydraulic head and loading.

Specify smooth or textured surface based on slope stability calculations.

Request certified laboratory test reports for each production batch.

Evaluate seam strength requirements and field welding procedures.

Audit manufacturer production capacity and quality management systems.

Plan logistics for roll size, site storage and handling equipment.

Engineering Case Example

In an industrial wastewater treatment project, a 2.0 mm thick HDPE Geomembrane for Industrial was installed over a compacted clay subgrade with nonwoven geotextile protection. Factory prefabricated panels were field welded using hot wedge welding. Post-installation vacuum box testing confirmed seam integrity, and leak detection surveys recorded zero defects.

FAQ

Q1: What thickness is typical for heavy industrial use?

A: 1.5–2.5 mm is commonly specified.Q2: Can it resist strong acids and alkalis?

A: Yes, HDPE is highly resistant to most industrial chemicals.Q3: How are seams tested on site?

A: Vacuum box or air pressure testing methods.Q4: What is the typical roll width?

A: 5–8 meters depending on production line.Q5: Can it be installed in cold climates?

A: Yes, with controlled welding parameters.Q6: Does it require protective layers?

A: Yes, in most industrial applications geotextile is recommended.Q7: How long is the expected service life?

A: 30–50 years under proper design conditions.Q8: Can it be repaired if damaged?

A: Local patches can be thermally welded.Q9: Is textured surface necessary for flat ponds?

A: Usually not required for flat base areas.Q10: Is third-party inspection recommended?

A: Yes, for critical industrial containment projects.

CTA

To request formal quotation, technical datasheets, or industrial-grade samples of HDPE Geomembrane for Industrial, provide your project specifications and chemical exposure data for professional engineering support.

E-E-A-T Author Credentials

This content is prepared by a civil and environmental materials engineer with over 15 years of experience in geomembrane design, industrial containment system engineering and EPC project technical consulting.