Geomembrana LDPE

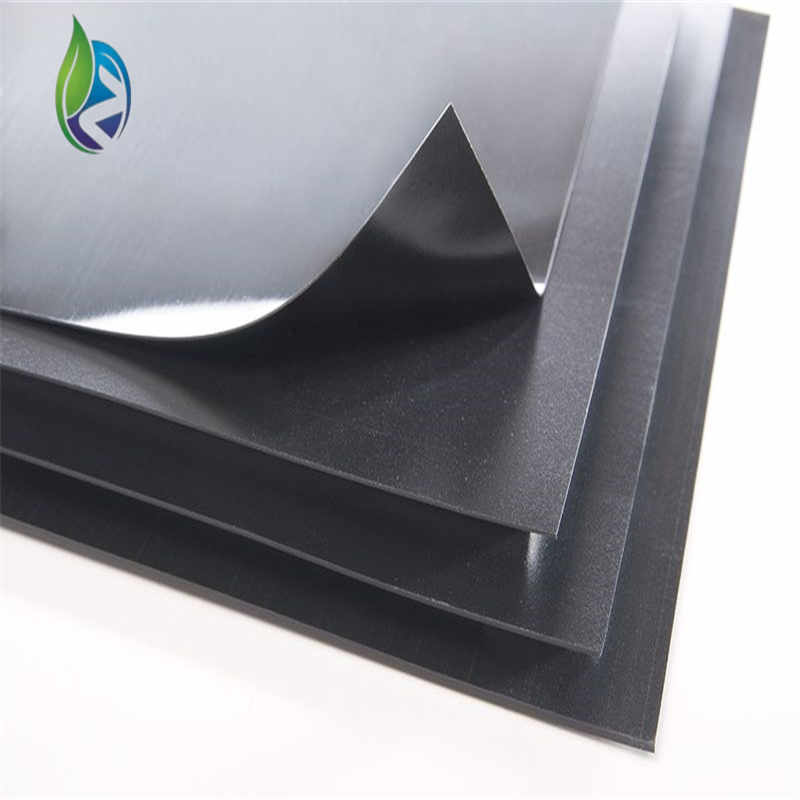

LDPE geomembrane, or Low Density Polyethylene geomembrane, is a flexible, lightweight, and highly impermeable synthetic material used primarily for waterproofing, containment, and environmental protection purposes. It is made from low density polyethylene resin, which provides excellent chemical resistance, flexibility, and durability. LDPE geomembrane differs from HDPE (High Density Polyethylene) geomembrane in its density and resulting properties. LDPE has a lower density, making it more flexible and easier to install, but it may have slightly lower tensile strength and temperature resistance compared to HDPE, which is denser and often used in applications requiring higher strength and stiffness.

LDPE Geomembrane Design for Environmental Protection: Flexible and Sustainable Barrier Solutions

LDPE geomembrane design for environmental protection is at the forefront of sustainable geotechnical engineering. As a low-density polyethylene-based liner, this geomembrane offers exceptional flexibility, chemical resistance, and impermeability, making it ideal for critical environmental applications. Whether in landfills, water reservoirs, or industrial containment areas, LDPE geomembrane design for environmental protection ensures long-term ecological safety and compliance with environmental regulations.

What Is LDPE Geomembrane Design for Environmental Protection?

LDPE geomembrane design for environmental protection refers to the use of engineered low-density polyethylene liners in containment systems aimed at protecting soil, groundwater, and surrounding ecosystems from contamination. The LDPE geomembrane design for environmental protection prioritizes durability, adaptability, and sustainability, providing an effective barrier against leachate, chemicals, and water seepage.

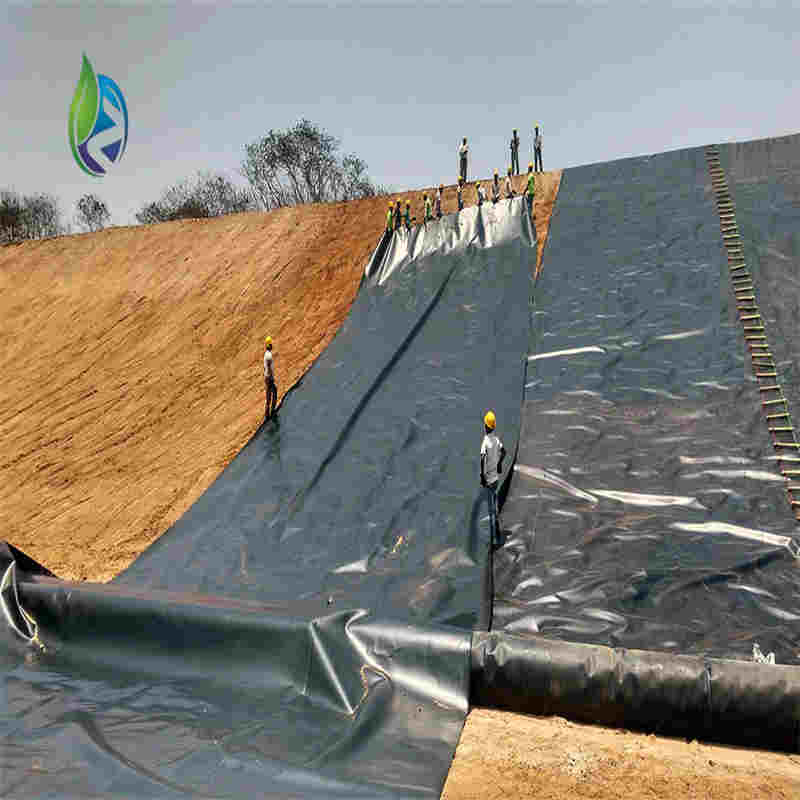

Unlike HDPE, LDPE geomembrane design for environmental protection is more flexible and easier to install in projects requiring complex contours and tight angles. Its softer structure makes it suitable for applications where thermal movement or structural settlement occurs.

Key Features of LDPE Geomembrane Design for Environmental Protection

Superior Flexibility

The flexible nature of LDPE geomembrane design for environmental protection allows for easier deployment and seamless conformation to irregular surfaces.Excellent Chemical Resistance

LDPE geomembrane design for environmental protection resists a wide range of chemicals, including acids, alkalis, oils, and solvents—ideal for industrial waste containment.Low Permeability

With high impermeability, the LDPE geomembrane design for environmental protection ensures long-lasting protection against fluid migration and soil contamination.UV and Weather Resistance

The UV-stabilized formulation of LDPE geomembrane design for environmental protection allows for long-term outdoor use without degradation.Environmentally Safe Material

100% recyclable and free of harmful additives, LDPE geomembrane design for environmental protection meets eco-conscious standards in construction.

Applications of LDPE Geomembrane Design for Environmental Protection

The LDPE geomembrane design for environmental protection is widely used in:

Sanitary Landfills

Prevents leachate leakage and protects groundwater from toxic substances.Mining and Industrial Waste Storage

Contains hazardous byproducts while ensuring operational safety and regulatory compliance.Water Reservoirs and Irrigation Ponds

Maintains water levels and prevents seepage in agricultural and municipal water management systems.Wastewater Treatment Plants

Acts as a primary containment barrier in sludge drying beds and effluent ponds.Oil and Gas Industry Projects

Provides containment under tanks, pipelines, and chemical storage zones.

Each application of LDPE geomembrane design for environmental protection contributes to minimizing ecological impact while maximizing efficiency and lifespan.

Why Choose LDPE Geomembrane Design for Environmental Protection?

Cost-Effective and Long-Lasting

Reduces long-term environmental liabilities and repair costs with a life expectancy of over 30 years.Quick and Simple Installation

Lightweight sheets simplify on-site handling and welding procedures.Proven Performance in Harsh Conditions

Functions reliably under thermal expansion, freezing temperatures, and chemical exposure.Customization Available

LDPE geomembrane design for environmental protection can be manufactured in different thicknesses (0.5mm to 2mm), roll widths, and colors based on project requirements.

Installation Best Practices

To achieve optimal performance from LDPE geomembrane design for environmental protection, follow these guidelines:

Prepare the Subgrade

Ensure a smooth and clean base, free from sharp stones or roots.Unroll and Position the Membrane

Place the LDPE geomembrane design for environmental protection with adequate overlaps.Seam Welding

Use hot wedge or extrusion welding for a continuous and watertight seal.Inspection and Testing

Perform air channel or vacuum box testing to verify the seam integrity.Backfilling and Covering

Protect the membrane from mechanical damage with geotextiles or soil cover layers.

Conclusion

As environmental regulations grow more stringent, investing in reliable containment solutions becomes essential. LDPE geomembrane design for environmental protection combines performance, safety, and adaptability to meet the demands of modern ecological engineering. From landfill liners to industrial containment zones, this geomembrane delivers uncompromised protection for the planet and future generations.

Choose LDPE geomembrane design for environmental protection to ensure your next infrastructure project meets the highest environmental standards—safely, efficiently, and sustainably.