Composite Geomembrane for Sale

Composite geomembrane with geotextile is a highly effective solution utilized in seepage control projects. This composite material combines the strength and durability of geotextile, typically a woven or non-woven fabric, with the impermeability of geomembrane, a flexible polymeric membrane. The geotextile reinforces the geomembrane, enhancing its resistance to punctures and tears, while the geomembrane provides a barrier against water seepage. The integration of these two materials forms a robust and seamless system that is ideal for applications such as dam liners, canal linings, and landfill covers, where strict impermeability and durability are crucial. The composite geomembrane with geotextile ensures long-term protection against seepage, maintaining structural integrity and environmental safety.

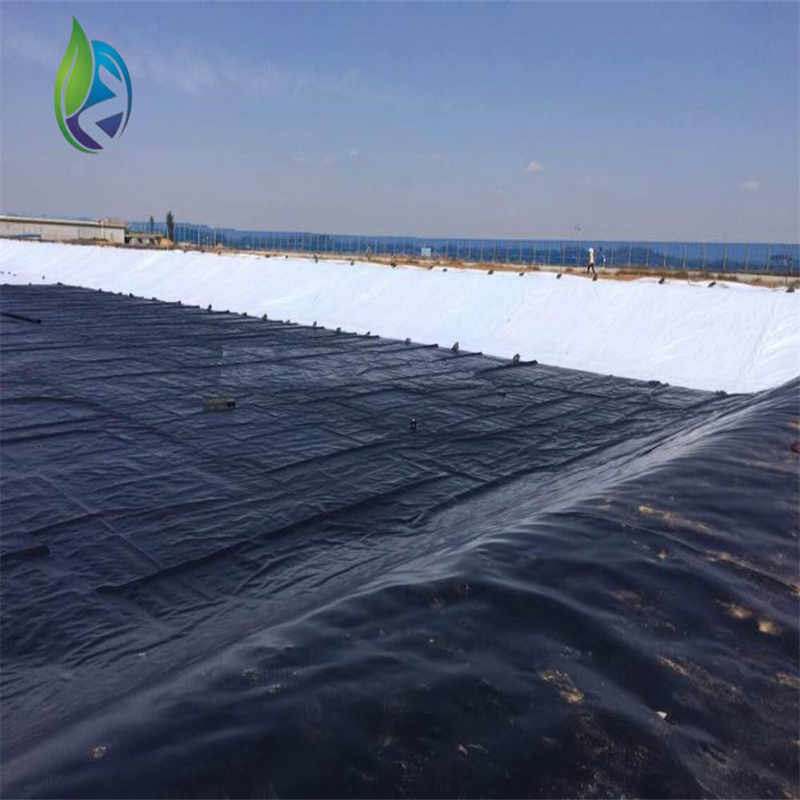

In modern civil engineering, mining, water conservancy, and environmental protection projects, composite geomembrane application in seepage control has become an industry-standard solution. This innovative material combines a geotextile with a geomembrane to deliver superior impermeability, tensile strength, and adaptability to uneven surfaces—making it ideal for long-term seepage prevention in a wide range of containment structures.

This article explores how composite geomembrane application in seepage control is transforming infrastructure integrity, minimizing water loss, and protecting natural resources.

What is a Composite Geomembrane?

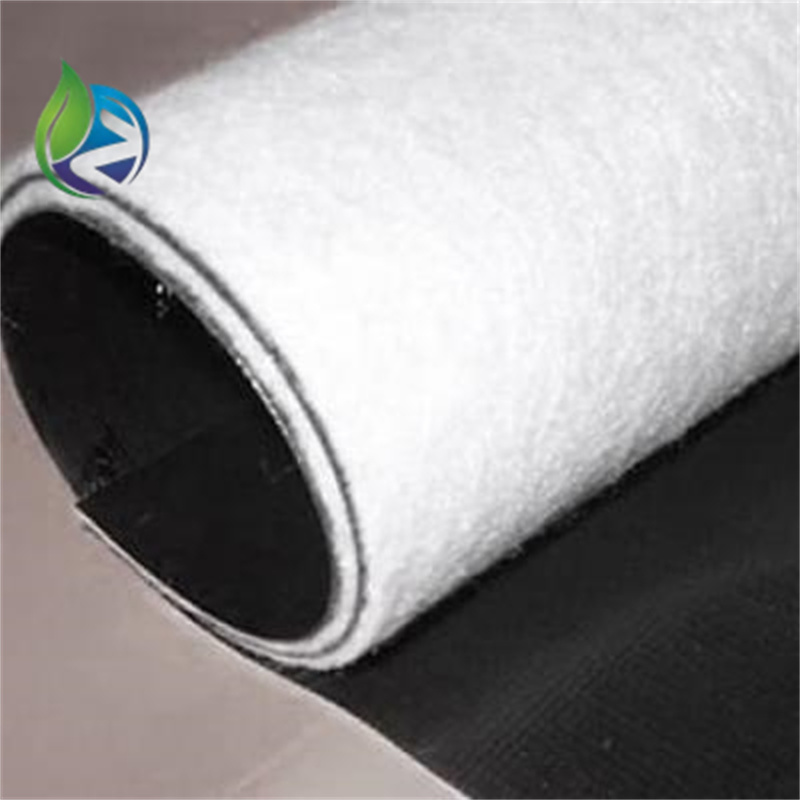

A composite geomembrane typically consists of one or two layers of geotextile bonded with one layer of geomembrane (usually HDPE, LDPE, or PVC). The geotextile provides reinforcement, cushioning, and filtration, while the geomembrane acts as the primary waterproofing barrier. This combination delivers a durable, flexible, and high-performance liner system.

In the context of seepage control, composite geomembranes are especially effective in scenarios where pure geomembrane liners may be prone to damage from pressure, sharp objects, or substrate movement.

Benefits of Composite Geomembrane Application in Seepage Control

The composite geomembrane application in seepage control offers a host of benefits that address common engineering challenges:

Superior Impermeability

The geomembrane core ensures near-zero permeability, making it ideal for reservoirs, landfills, and canals.Enhanced Tensile Strength

The geotextile layer adds mechanical robustness, helping the composite geomembrane resist tearing, puncture, and installation damage.Improved Subgrade Adaptability

On uneven or rough surfaces, the geotextile cushioning allows the geomembrane to conform and maintain effective sealing performance.Long-Term Durability

With UV stabilization and chemical resistance, composite geomembranes can last 20+ years in buried applications.Cost-Effective and Easy to Install

Fewer installation errors, reduced need for soil preparation, and minimal maintenance lower the total cost of ownership.

Core Applications of Composite Geomembrane in Seepage Control

The composite geomembrane application in seepage control is widely used in the following sectors:

Irrigation Canals and Reservoirs: Prevents seepage loss, conserving water in agricultural systems.

Landfills: Acts as a bottom liner and capping layer to prevent leachate from polluting groundwater.

Mining Tailings and Slurry Ponds: Withstands chemical exposure while ensuring full containment.

Wastewater Treatment Plants: Offers reliable leakage protection in sludge lagoons and storage tanks.

Tunnel and Underground Constructions: Provides waterproofing in subway systems and highway tunnels.

The adaptability of composite geomembrane application in seepage control makes it an indispensable solution for both temporary and permanent engineering projects.

Installation Best Practices

To maximize the effectiveness of composite geomembrane application in seepage control, proper installation is key:

Ensure a smooth and compacted base layer before deployment.

Overlap adjacent sheets with adequate welding (hot wedge, extrusion, or heat sealing).

Use qualified technicians to verify seam integrity using non-destructive testing methods.

Employ protective layers (such as geotextiles or sand bedding) above and below for added durability.

Regular post-installation inspection ensures that the composite geomembrane application in seepage control performs to its full potential for decades.

Technical Specifications to Consider

When selecting a material for composite geomembrane application in seepage control, pay attention to:

Thickness: Common options range from 0.5mm to 2.0mm depending on the project scale and risk factor.

Tensile Strength: Essential for high-load or shifting conditions.

UV and Chemical Resistance: Especially for exposed or industrial environments.

Roll Width and Length: Affects seaming frequency and installation speed.

Always request third-party quality certificates (such as ASTM, GRI, or ISO) from the supplier.

Choosing the Right Supplier

For effective composite geomembrane application in seepage control, working with a reliable supplier is essential. A reputable manufacturer should offer:

Custom roll sizing and lamination configurations

On-site technical support or installation guidance

Verified field performance and references

Competitive pricing with short lead times

Choosing a partner with extensive experience in composite geomembrane application in seepage control ensures reduced risk, better compliance, and long-term cost savings.

Conclusion

The composite geomembrane application in seepage control represents a significant advancement in waterproofing technology. With its dual-layer structure, exceptional strength, and adaptability, it provides superior performance across diverse environmental and civil engineering projects. Whether you're planning a water reservoir, landfill, or mine tailings pond, this solution delivers sustainable, cost-efficient, and regulation-compliant seepage control.

By understanding the strengths and application potential of composite geomembrane in seepage control, you can make informed decisions that protect both your infrastructure and the environment.

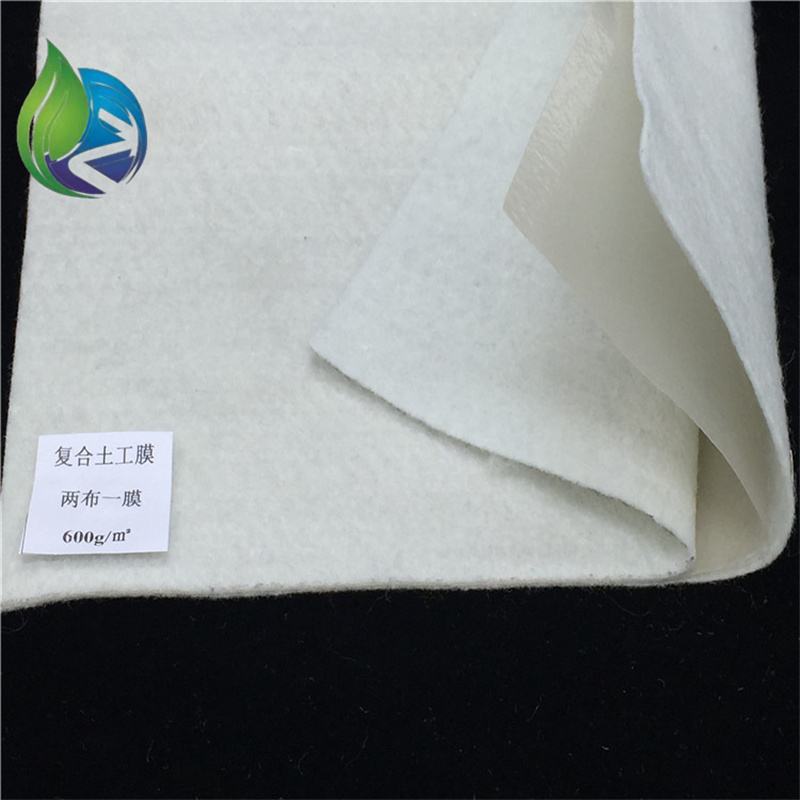

Two cloth one film: