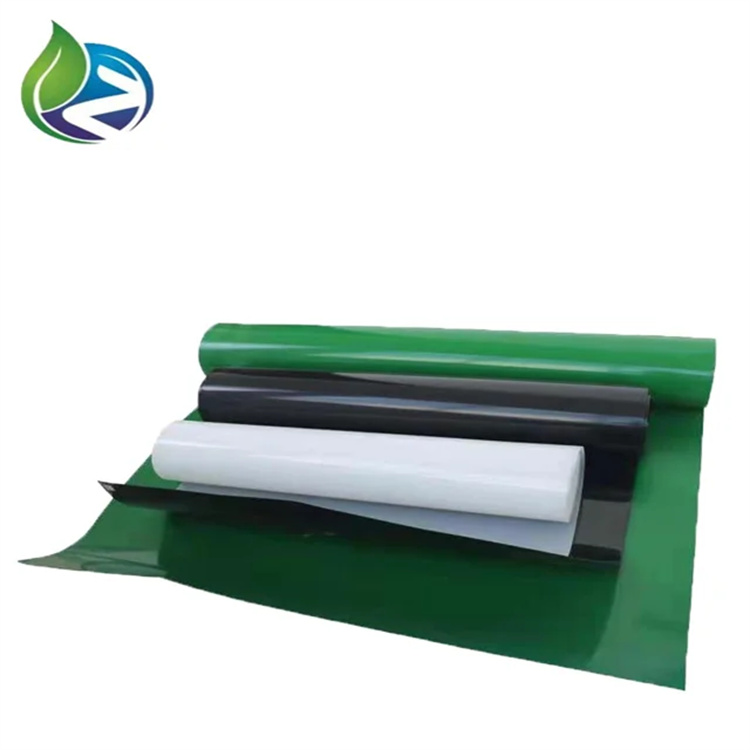

Black Hdpe Geomembrane

Manufacturing Process

The production of Black HDPE Geomembrane follows a controlled, engineering-grade manufacturing workflow:

Raw Material Preparation: Virgin HDPE resin blended with carbon black and stabilizers

Extrusion: Flat die or blown film extrusion equipment forms uniform sheets

Thickness Control: Automatic gauge control ensures tolerance within ±5%

Surface Treatment: Smooth or textured embossing based on application

Cooling & Annealing: Controlled cooling to reduce internal stress

Inspection & Testing: Mechanical, dimensional, and dispersion tests

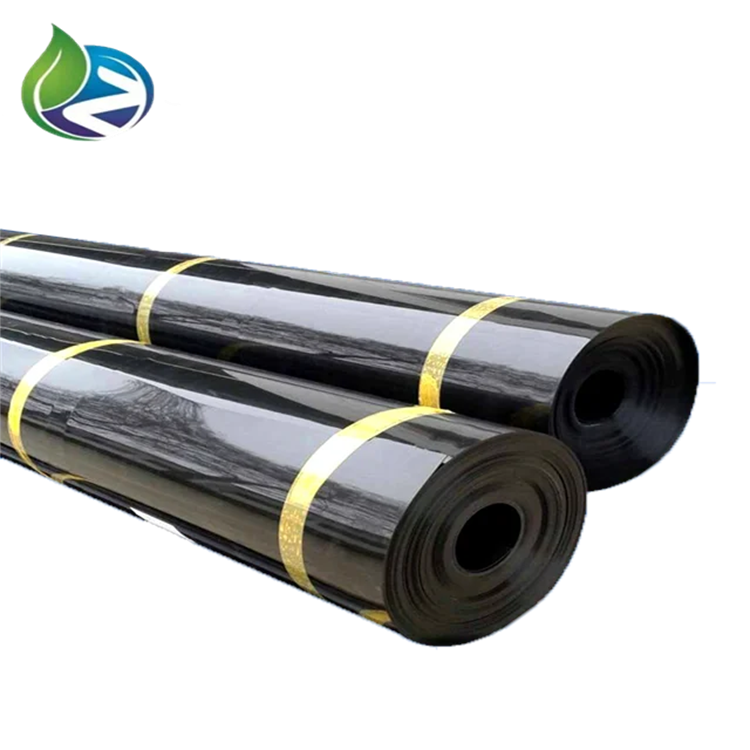

Rolling & Packaging: Packed for transport with moisture and UV protection

Product Definition

Black HDPE Geomembrane is a high-density polyethylene impermeable liner engineered for long-term containment, separation, and environmental protection applications. It offers excellent chemical resistance, UV stability, and mechanical strength for demanding civil and industrial engineering projects.

Technical Parameters and Specifications

All parameters below are aligned with commonly accepted international engineering practices and testing standards.

Material: High Density Polyethylene (HDPE)

Color: Black (carbon black content 2.0%–3.0%)

Thickness Range: 0.5 mm – 3.0 mm

Density: ≥ 0.94 g/cm³

Tensile Strength at Yield: ≥ 15 MPa

Elongation at Break: ≥ 700%

Puncture Resistance: ≥ 500 N

Carbon Black Dispersion: Grade 1–2

Service Temperature: -40°C to +60°C

Expected Service Life: > 50 years (proper installation)

Structure and Material Composition

Black HDPE Geomembrane is designed as a homogeneous or co-extruded polymer sheet with the following structure:

Primary Resin Layer: Virgin HDPE resin providing mechanical strength

Carbon Black Additive: UV protection and oxidation resistance

Antioxidant Package: Thermal and long-term aging resistance

Optional Textured Surface: Enhanced friction for slope stability

Manufacturing Process

The production of Black HDPE Geomembrane follows a controlled, engineering-grade manufacturing workflow:

Raw Material Preparation: Virgin HDPE resin blended with carbon black and stabilizers

Extrusion: Flat die or blown film extrusion equipment forms uniform sheets

Thickness Control: Automatic gauge control ensures tolerance within ±5%

Surface Treatment: Smooth or textured embossing based on application

Cooling & Annealing: Controlled cooling to reduce internal stress

Inspection & Testing: Mechanical, dimensional, and dispersion tests

Rolling & Packaging: Packed for transport with moisture and UV protection

Industry Comparison

| Material | Permeability | Chemical Resistance | Service Life | Typical Cost Level |

|---|---|---|---|---|

| Black HDPE Geomembrane | Extremely Low | Excellent | 50+ Years | Medium |

| LDPE Geomembrane | Low | Moderate | 25–30 Years | Low |

| PVC Liner | Low | Limited | 15–20 Years | Medium |

| Clay Liner | Moderate | Poor | Variable | Low |

Application Scenarios

Black HDPE Geomembrane is widely used across infrastructure and environmental engineering sectors:

Landfill bottom liners and capping systems

Mining leach pads and tailings dams

Wastewater treatment lagoons

Water reservoirs and canals

Industrial containment ponds

Agricultural irrigation storage

Core Pain Points and Solutions

Leakage Risk: Solved by ultra-low permeability HDPE structure

UV Degradation: Carbon black stabilizes long-term outdoor exposure

Chemical Attack: HDPE resists acids, alkalis, and hydrocarbons

Slope Instability: Textured geomembranes improve interface friction

Risk Warnings and Mitigation Measures

Avoid subgrade sharp objects; use protective geotextile

Ensure certified welding technicians for seam integrity

Control thermal expansion during installation

Perform non-destructive seam testing before commissioning

Procurement and Selection Guide

Define application environment and chemical exposure

Select appropriate thickness based on load conditions

Choose smooth or textured surface as required

Verify compliance with project specifications

Request batch testing reports

Confirm installation support and welding guidance

Engineering Case Example

In a municipal landfill expansion project, a 2.0 mm Black HDPE Geomembrane was installed over a compacted clay layer with protective geotextile. Dual-track hot wedge welding was applied, followed by air pressure testing. The system achieved zero leakage during commissioning and has remained operational under leachate exposure for over eight years.

Frequently Asked Questions

Q1: What thickness is most common?

A: 1.5–2.0 mm for containment projects.Q2: Is it suitable for drinking water?

A: Yes, with appropriate certification.Q3: Can it be welded onsite?

A: Yes, using hot wedge or extrusion welding.Q4: How long does installation take?

A: Depends on area and complexity.Q5: Does black color affect performance?

A: Yes, improves UV resistance.Q6: Is textured always better?

A: Only for slope applications.Q7: Can recycled HDPE be used?

A: Not recommended for critical containment.Q8: What testing is required?

A: Tensile, puncture, dispersion, seam tests.Q9: How is it transported?

A: Rolled and wrapped for protection.Q10: Can it be repaired?

A: Yes, via localized patch welding.

Call to Action

For project-specific quotations, detailed technical datasheets, or engineering samples of Black HDPE Geomembrane, please submit your requirements to our technical sales team for professional support.

E-E-A-T Author Credentials

This article is prepared by a materials engineering team with over 15 years of experience in geosynthetics manufacturing, quality control, and large-scale civil engineering applications, supporting EPC contractors and international distributors worldwide.