0.75mm Geomembrane Liner

Manufacturing Process

Engineering-grade production workflow:

Raw Material Preparation: Virgin HDPE resin + carbon black masterbatch

Drying System: Dehumidifying hopper dryers to control moisture below 0.1%

Flat Die Extrusion: Multi-manifold extrusion system with temperature control (180–220°C)

Calendaring: Precision roller smoothing and thickness calibration

Surface Embossing: Optional micro-texture rollers

Cooling Section: Controlled water-cooled conveyors

Online Quality Control: Laser thickness gauges and spark leakage testers

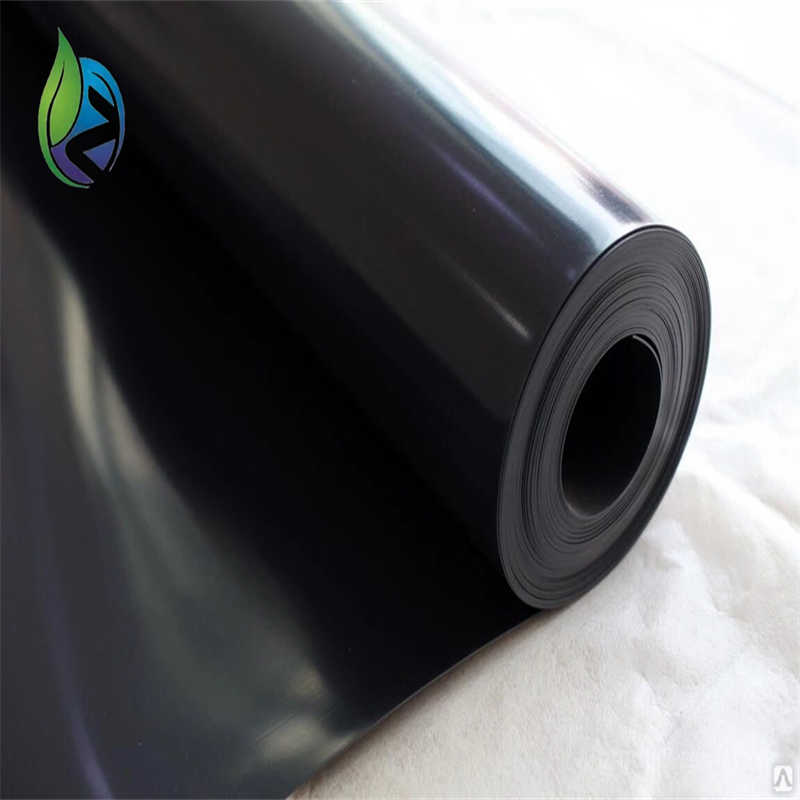

Roll Winding: Automatic tension-controlled winding systems

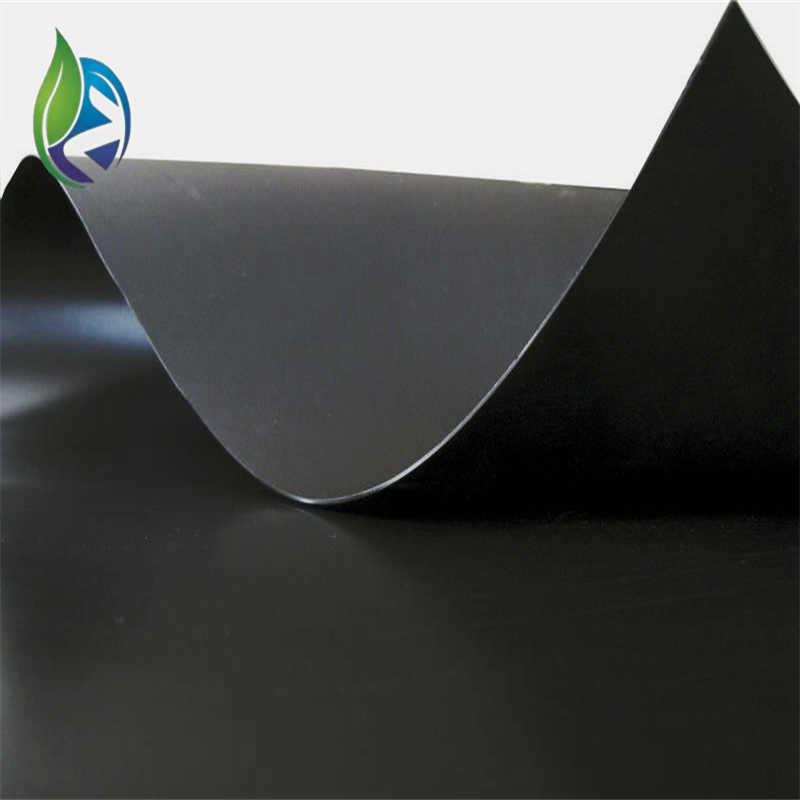

Product Definition

The 0.75mm Geomembrane Liner is a medium-duty impermeable polymer sheet engineered for industrial liquid containment, groundwater isolation, and environmental protection systems. It provides controlled barrier performance, chemical resistance, and mechanical stability for engineered landfills, wastewater ponds, and industrial storage facilities.

Technical Parameters and Specifications

All values align with common international geosynthetic engineering practices.

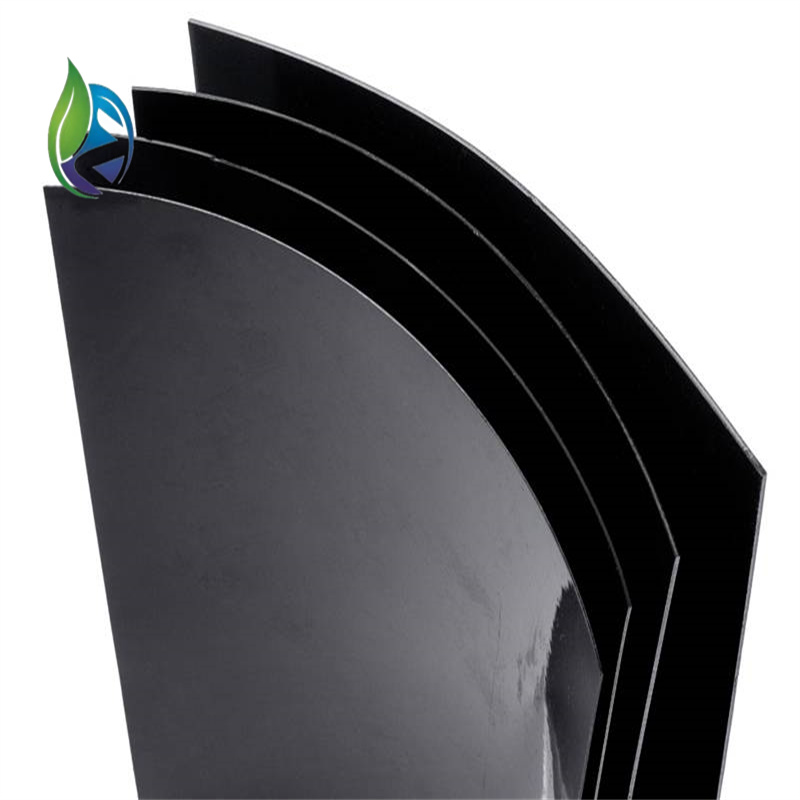

Nominal Thickness: 0.75 mm (±10%)

Sheet Width: 5.0–8.0 m

Roll Length: 50–200 m

Density: ≥ 0.94 g/cm³

Tensile Strength at Yield: ≥ 14 kN/m

Elongation at Break: ≥ 700%

Puncture Resistance (CBR): ≥ 1.6 kN

Carbon Black Content: 2.0–3.0%

Service Temperature Range: -40°C to +60°C

Structure and Material Composition

Layered functional structure:

Top Protective Layer: UV-stabilized HDPE surface

Core Barrier Layer: High-density polyethylene matrix

Bottom Adhesion Layer: Micro-textured anchoring surface

Manufacturing Process

Engineering-grade production workflow:

Raw Material Preparation: Virgin HDPE resin + carbon black masterbatch

Drying System: Dehumidifying hopper dryers to control moisture below 0.1%

Flat Die Extrusion: Multi-manifold extrusion system with temperature control (180–220°C)

Calendaring: Precision roller smoothing and thickness calibration

Surface Embossing: Optional micro-texture rollers

Cooling Section: Controlled water-cooled conveyors

Online Quality Control: Laser thickness gauges and spark leakage testers

Roll Winding: Automatic tension-controlled winding systems

Industry Comparison

| Material | Thickness Range | Chemical Resistance | Service Life | Typical Cost Level |

|---|---|---|---|---|

| 0.75mm Geomembrane Liner | 0.75 mm | High | 25–30 Years | Medium |

| Clay Liner | 300–600 mm | Low | 10–15 Years | Low |

| Concrete Lining | 80–150 mm | Medium | 20–25 Years | High |

Application Scenarios

Industrial Wastewater Treatment Plants – basin and pond lining

Landfill Leachate Containment Systems

Chemical Storage Secondary Containment

Mining Heap Leach Pads

Power Plant Ash Ponds

Core Pain Points and Engineering Solutions

Leakage Risk: Continuous welded seams with dual-track hot wedge welding

Chemical Degradation: Carbon-black UV stabilization and antioxidant packages

Subgrade Puncture: Protective geotextile cushion layers

Thermal Expansion: Anchoring trench and slack allowance design

Risk Warnings and Mitigation Recommendations

Risk: Poor seam fusion due to low ambient temperature

Mitigation: Preheating welding zonesRisk: Subgrade settlement

Mitigation: Compacted soil foundation and geotechnical verificationRisk: UV aging during storage

Mitigation: Store under protective covers

Procurement and Selection Guide

Confirm chemical compatibility with stored liquids

Define hydraulic head and leakage tolerance

Evaluate subgrade roughness and puncture risk

Specify welding method and seam testing standard

Require factory quality traceability documents

Request third-party laboratory test reports

Plan logistics for roll width and site handling

Engineering Application Case

In a 45,000 m² industrial wastewater lagoon project, the 0.75mm Geomembrane Liner was installed over a compacted clay subgrade with nonwoven geotextile protection. Double-track welds and air-channel testing achieved leak detection rates below engineering thresholds, ensuring stable long-term containment performance.

FAQ

Q1: Is 0.75mm suitable for landfill bases? A: Suitable for secondary lining systems.

Q2: Can it resist acidic liquids? A: Yes, within typical industrial pH ranges.

Q3: Typical overlap width? A: 100–150 mm.

Q4: Welding temperature? A: Typically 300–450°C wedge temperature.

Q5: Storage duration before installation? A: Up to 12 months in covered conditions.

Q6: Compatible with concrete? A: Yes, with separation layers.

Q7: Fire resistance? A: Self-extinguishing formulations available.

Q8: Can it be repaired on site? A: Yes, via extrusion welding patches.

Q9: UV resistance duration? A: Designed for extended outdoor exposure.

Q10: Cold climate performance? A: Stable down to -40°C.

Call to Action

For formal quotations, technical datasheets, or engineered sample requests of the 0.75mm Geomembrane Liner, please contact the technical sales department with full project parameters.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineering specialist with 15+ years of experience in landfill design, industrial containment systems, and international geotechnical project consulting.