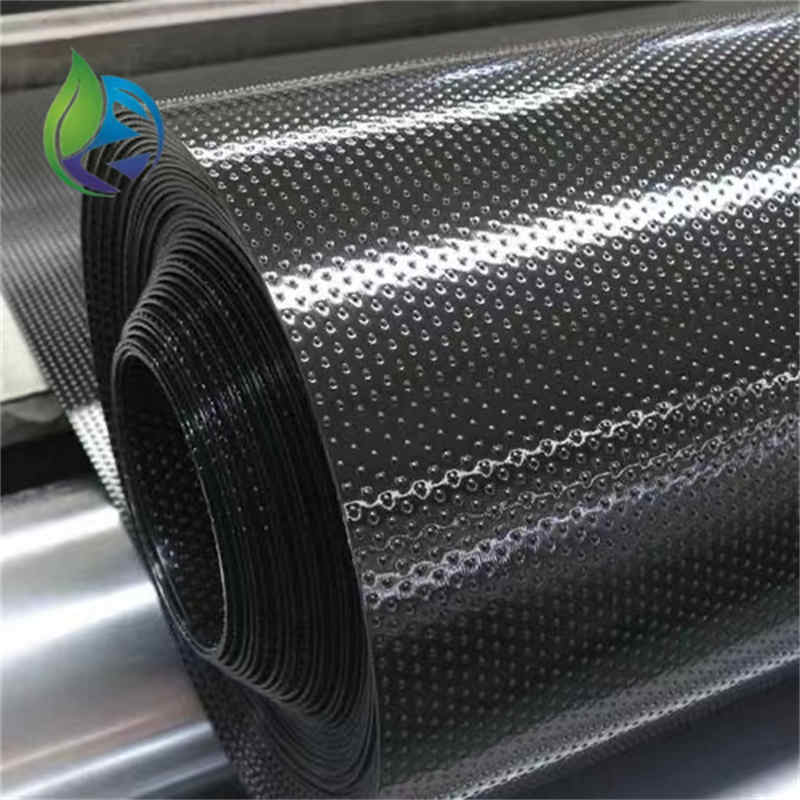

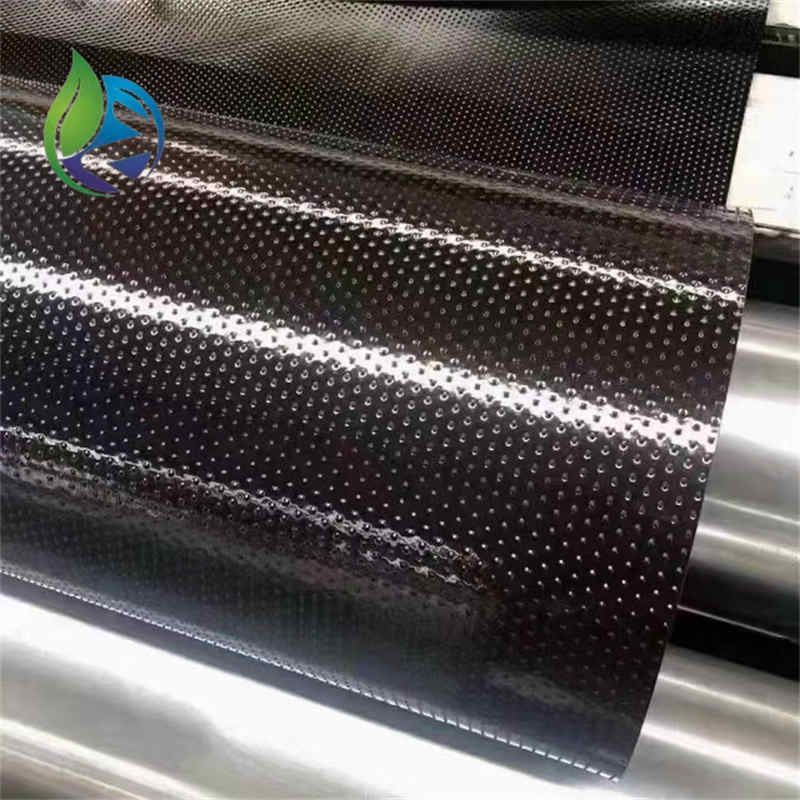

Textured HDPE Geomembrane

Manufacturing Process

Textured HDPE Geomembrane is produced using controlled extrusion and surface modification processes.

Virgin HDPE resin inspection and formulation

High-temperature flat-die extrusion

Inline or post-extrusion texturing using nitrogen injection or embossing technology

Automated thickness and surface roughness monitoring

Controlled cooling to lock surface texture

Roll winding under controlled tension

Mechanical, physical, and durability testing

Product Definition

Textured HDPE Geomembrane is a high-density polyethylene impermeable liner with engineered surface roughness on one or both sides, designed to increase interface friction and slope stability in containment and lining systems used in demanding civil and environmental engineering projects.

Technical Parameters and Specifications

Textured HDPE Geomembrane is manufactured to meet internationally recognized geomembrane performance standards for high-risk containment applications.

Thickness Range: 1.0 mm – 3.0 mm

Density: ≥ 0.940 g/cm³

Tensile Strength at Yield: ≥ 15 MPa

Tensile Strength at Break: ≥ 20 MPa

Elongation at Break: ≥ 700%

Puncture Resistance: ≥ 500 N

Tear Resistance: ≥ 250 N

Carbon Black Content: 2.0% – 3.0%

Oxidative Induction Time (Standard OIT): ≥ 100 minutes

Oxidative Induction Time (High Pressure OIT): ≥ 400 minutes

Service Temperature Range: -40°C to +60°C

Standard Roll Width: 5.8 m – 7.0 m

Surface Texture Type: Single-sided or double-sided

Structure and Material Composition

The structural design of Textured HDPE Geomembrane combines mechanical strength with enhanced interfacial friction.

HDPE Base Resin: Virgin high-density polyethylene for high stiffness and chemical resistance

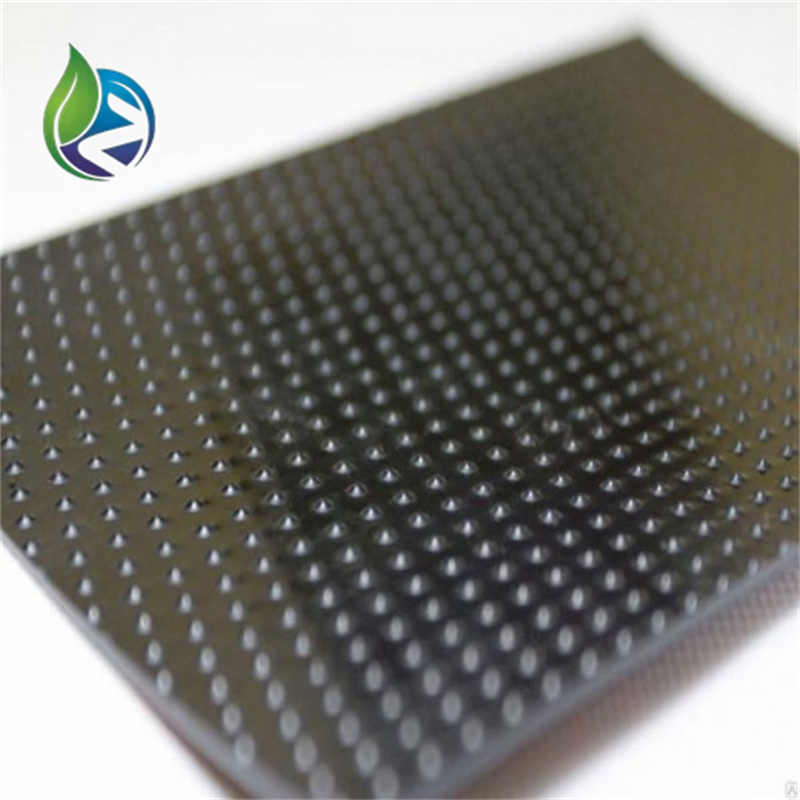

Textured Surface Layer: Engineered asperities to increase friction angle

Carbon Black: UV protection and long-term aging resistance

Antioxidant Package: Improves thermal and oxidative stability

Manufacturing Process

Textured HDPE Geomembrane is produced using controlled extrusion and surface modification processes.

Virgin HDPE resin inspection and formulation

High-temperature flat-die extrusion

Inline or post-extrusion texturing using nitrogen injection or embossing technology

Automated thickness and surface roughness monitoring

Controlled cooling to lock surface texture

Roll winding under controlled tension

Mechanical, physical, and durability testing

Industry Comparison

| Material | Surface Friction | Chemical Resistance | Slope Stability | Relative Cost | Typical Application |

|---|---|---|---|---|---|

| Textured HDPE Geomembrane | Very High | Excellent | Excellent | Medium-High | Landfill slopes, heap leach pads |

| Smooth HDPE Geomembrane | Low | Excellent | Moderate | Medium | Flat containment areas |

| Textured LLDPE Geomembrane | High | Good | High | Medium | Irregular subgrades |

| PVC Geomembrane | Moderate | Moderate | Low | Low-Medium | Light-duty lining |

Application Scenarios

Textured HDPE Geomembrane is specified by EPC contractors, engineering consultants, and distributors for:

Municipal and hazardous waste landfill slopes

Mining heap leach pads and tailings facilities

Steep-sided wastewater treatment lagoons

Secondary containment for industrial tanks

Earth dam upstream and downstream lining

High-risk containment systems requiring shear resistance

Core Engineering Pain Points and Solutions

Interface sliding on slopes: Textured surface increases friction angle

Liner instability under load: High tensile strength resists deformation

Chemical exposure: HDPE provides excellent chemical resistance

Long-term aging: Antioxidant-stabilized formulation extends service life

Risk Warnings and Mitigation Recommendations

Ensure compatibility testing with adjacent geosynthetics

Control welding temperature to avoid damaging textured surface

Perform interface shear testing for critical slope designs

Avoid excessive dragging that may flatten surface texture

Implement rigorous QA/QC during installation

Procurement and Selection Guide

Define slope angle and stability requirements

Select single-sided or double-sided texture based on interface conditions

Determine thickness according to load and regulatory standards

Verify compliance with GRI GM13 or equivalent specifications

Request interface friction and shear test data

Evaluate supplier manufacturing technology and consistency

Plan installation and quality assurance procedures

Engineering Case Application

In a mining heap leach project, a 2.0 mm double-sided Textured HDPE Geomembrane was installed on a 3H:1V slope beneath a geotextile protection layer. Interface shear testing confirmed adequate stability, and the system has maintained liner integrity under sustained ore loading.

Frequently Asked Questions (FAQ)

What is the main advantage of textured HDPE? — Improved slope stability.

Is it suitable for flat areas? — Yes, but often unnecessary.

Can it be welded like smooth HDPE? — Yes, with proper parameter control.

What texture types are available? — Single-sided and double-sided.

Does texture reduce chemical resistance? — No.

What thickness is common for landfills? — Typically 1.5–2.5 mm.

Is interface shear testing required? — Recommended for slope designs.

Does texture affect service life? — No, if properly stabilized.

Can it be used with geotextiles? — Yes, commonly.

What standards apply? — GRI GM13 and relevant ASTM tests.

Call to Action

For project-specific quotations, detailed technical datasheets, interface shear test reports, or engineering samples of Textured HDPE Geomembrane, please submit your project parameters to our technical sales and engineering team.

E-E-A-T Author Credentials

This article is authored by a senior geosynthetics engineer with over 15 years of experience in HDPE geomembrane design, manufacturing quality control, and EPC project support for landfill, mining, and infrastructure applications worldwide.