Landfill Liner

Manufacturing Process

Raw Material Selection: Virgin polyethylene resin with stabilizers

Compounding: Addition of carbon black, antioxidants, UV inhibitors

Extrusion: Flat die or blown film extrusion to form geomembrane sheets

Surface Treatment: Optional texturing for slope stability

Thickness Control: Automated gauge and laser monitoring

Cooling and Annealing: Dimensional stabilization

Quality Testing: Mechanical, oxidative induction, permeability testing

Rolling and Packaging: Protection for transportation and storage

Product Definition

Landfill Liner is an engineered containment system designed to prevent leachate migration from municipal or hazardous waste landfills into surrounding soil and groundwater, using low-permeability materials and composite structures to meet long-term environmental protection and regulatory compliance requirements.

Technical Parameters and Specifications

Liner type: Single liner / Composite liner / Double liner system

Primary geomembrane material: HDPE / LLDPE

Geomembrane thickness: 1.0 mm – 3.0 mm

Hydraulic conductivity (geomembrane): ≤1×10⁻¹³ cm/s

Compacted clay layer permeability: ≤1×10⁻⁷ cm/s

Sheet width: 5.8 m – 8.0 m

Carbon black content: 2.0% – 3.0%

Tensile strength at yield: ≥15 MPa

Elongation at break: ≥700%

Interface friction angle (textured liner): 22° – 34°

Design service life: ≥50 years (buried condition)

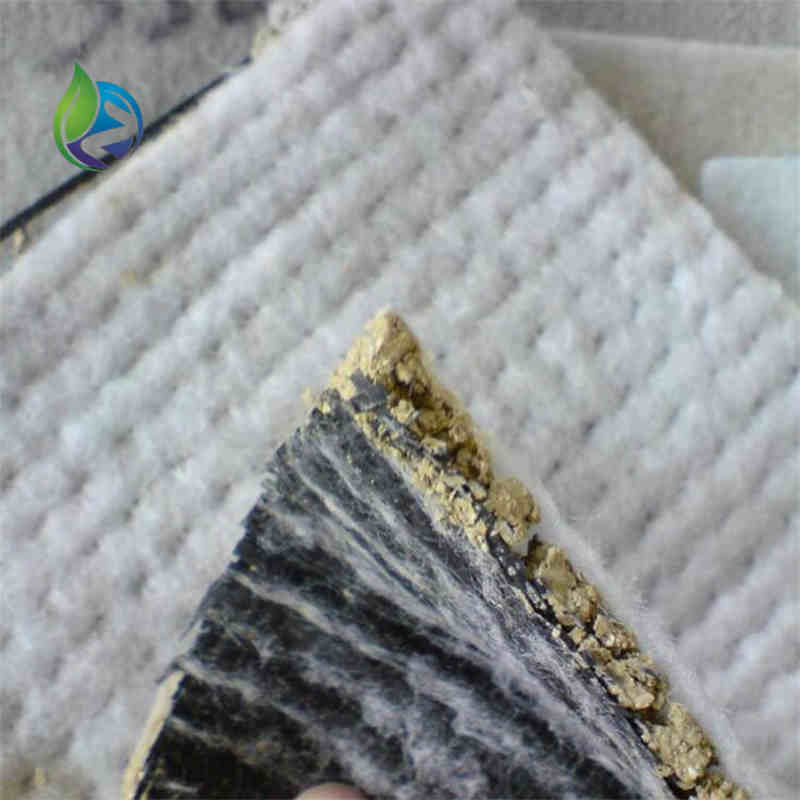

Structure and Material Composition

Waste Layer: Municipal, industrial, or hazardous waste mass

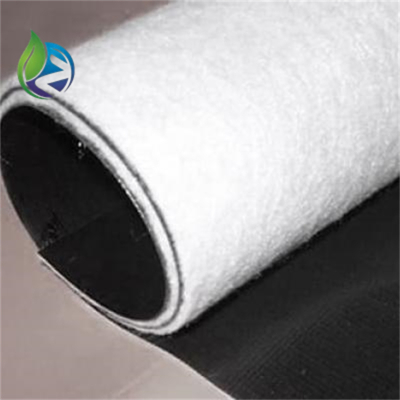

Protective Geotextile: Nonwoven fabric preventing puncture damage

Primary Geomembrane: HDPE or LLDPE impermeable barrier

Secondary Geomembrane: Backup containment layer

Compacted Clay or GCL: Low-permeability mineral barrier

Prepared Subgrade: Engineered foundation soil

Manufacturing Process

Raw Material Selection: Virgin polyethylene resin with stabilizers

Compounding: Addition of carbon black, antioxidants, UV inhibitors

Extrusion: Flat die or blown film extrusion to form geomembrane sheets

Surface Treatment: Optional texturing for slope stability

Thickness Control: Automated gauge and laser monitoring

Cooling and Annealing: Dimensional stabilization

Quality Testing: Mechanical, oxidative induction, permeability testing

Rolling and Packaging: Protection for transportation and storage

Industry Comparison

| Parameter | Geomembrane Liner | Compacted Clay Liner | Composite Liner |

|---|---|---|---|

| Hydraulic Performance | Excellent | Moderate | Excellent |

| Construction Consistency | High | Highly variable | High |

| Space Requirement | Minimal | Large | Moderate |

| Long-Term Reliability | High | Risk of cracking | Highest |

| Regulatory Acceptance | Widely accepted | Limited | Preferred |

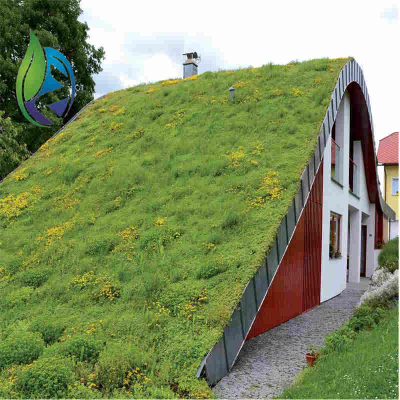

Application Scenarios

Municipal solid waste landfills

Hazardous waste disposal facilities

Industrial waste containment sites

Mining tailings and residue storage

EPC environmental protection projects

Core Pain Points and Solutions

Leachate leakage risk: Composite landfill liner systems provide redundancy

Subgrade settlement: Flexible geomembranes accommodate deformation

Slope instability: Textured liners increase interface shear strength

Long-term degradation: Stabilized polymers ensure durability over decades

Risk Warnings and Mitigation Measures

Puncture damage during installation; use protective geotextiles

Improper welding parameters; require certified welding technicians

Excessive UV exposure; limit outdoor storage duration

Inadequate quality control; implement full CQA/CQC programs

Procurement and Selection Guide

Identify waste type and regulatory requirements

Select appropriate liner system configuration

Determine geomembrane thickness based on load conditions

Specify smooth or textured surfaces for slope stability

Verify laboratory test reports and certifications

Evaluate supplier manufacturing capacity and project experience

Confirm availability of technical support and documentation

Engineering Case Study

In a municipal landfill expansion project with a design capacity exceeding 3 million cubic meters, a composite landfill liner system consisting of a 2.0 mm HDPE geomembrane and a compacted clay layer was installed. Leak detection monitoring over five years demonstrated zero measurable leachate escape, meeting stringent environmental compliance requirements.

FAQ

What is the primary function of a landfill liner? — Prevent leachate migration.

Why are composite liners preferred? — They provide redundant protection.

What thickness is commonly used? — Typically 1.5–2.5 mm for geomembranes.

Is textured liner necessary? — Required on steep slopes.

How is liner integrity tested? — Non-destructive seam testing and CQA.

What standards apply? — ASTM, GRI-GM13, and local regulations.

Can liners accommodate settlement? — Yes, polymer liners are flexible.

What is the expected lifespan? — Over 50 years when properly installed.

Is on-site welding required? — Yes, thermal fusion welding is standard.

Can landfill liners be repaired? — Localized repairs are feasible.

Call to Action

For detailed landfill liner specifications, compliance documentation, engineering consultation, or commercial quotations, please submit your project requirements to receive a professional technical response.

E-E-A-T Author Credentials

This article is prepared by environmental and geotechnical engineers with over 15 years of experience in landfill engineering, containment systems, and EPC project support, serving global contractors, consultants, and procurement teams.