Custom Composite Geomembrane

Manufacturing Process

Custom Composite Geomembrane manufacturing emphasizes precision bonding and performance consistency.

Selection of polymer resin and geotextile specifications based on design

Extrusion or calendering of geomembrane sheets

Nonwoven geotextile production and surface preparation

Thermal lamination or hot-melt bonding of layers

Online thickness, peel strength, and surface inspection

Cooling, trimming, roll formation, and quality testing

Product Definition

Custom Composite Geomembrane is a project-oriented geosynthetic barrier system manufactured by bonding geomembranes with geotextiles or functional layers according to specific engineering requirements. It integrates impermeability, protection, filtration, and mechanical adaptability to meet complex hydraulic and environmental design conditions.

Technical Parameters and Specifications

Custom Composite Geomembrane parameters are defined based on design loads, seepage control targets, and service environment. Typical engineering ranges include:

Composite Configuration: Geotextile + Geomembrane + Geotextile (or single-sided)

Geomembrane Thickness: 0.3 mm – 2.0 mm

Geotextile Type: Nonwoven needle-punched

Geotextile Mass: 200 – 1000 g/m²

Tensile Strength: ≥ 8–15 kN/m (direction-dependent)

Peel Strength: ≥ 30 N/cm

Hydrostatic Pressure Resistance: ≥ 0.6–1.0 MPa

Permeability Coefficient: ≤ 1 × 10⁻¹³ cm/s

Service Temperature Range: -40°C to +80°C

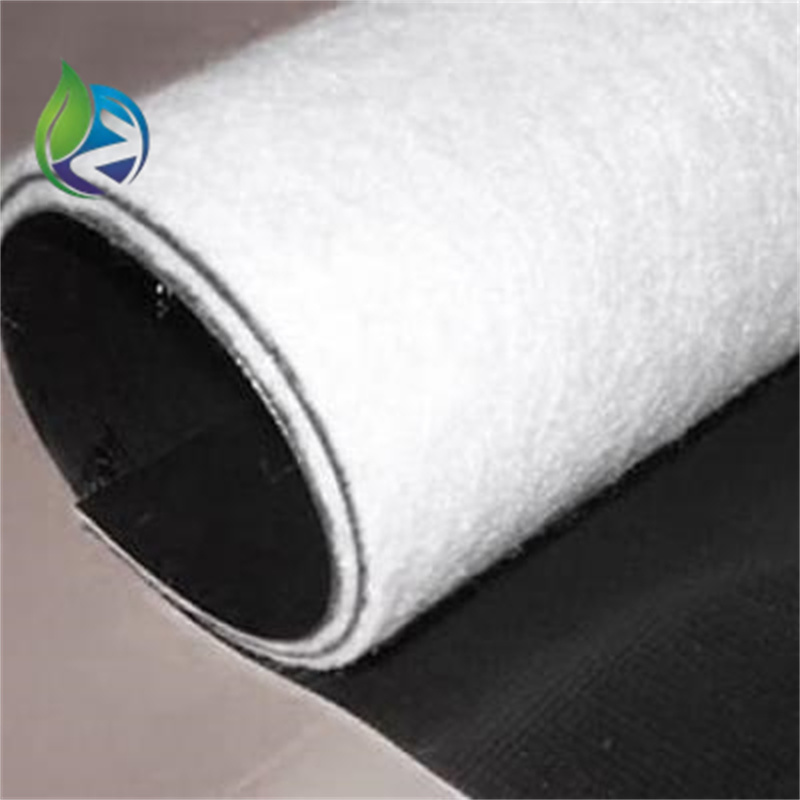

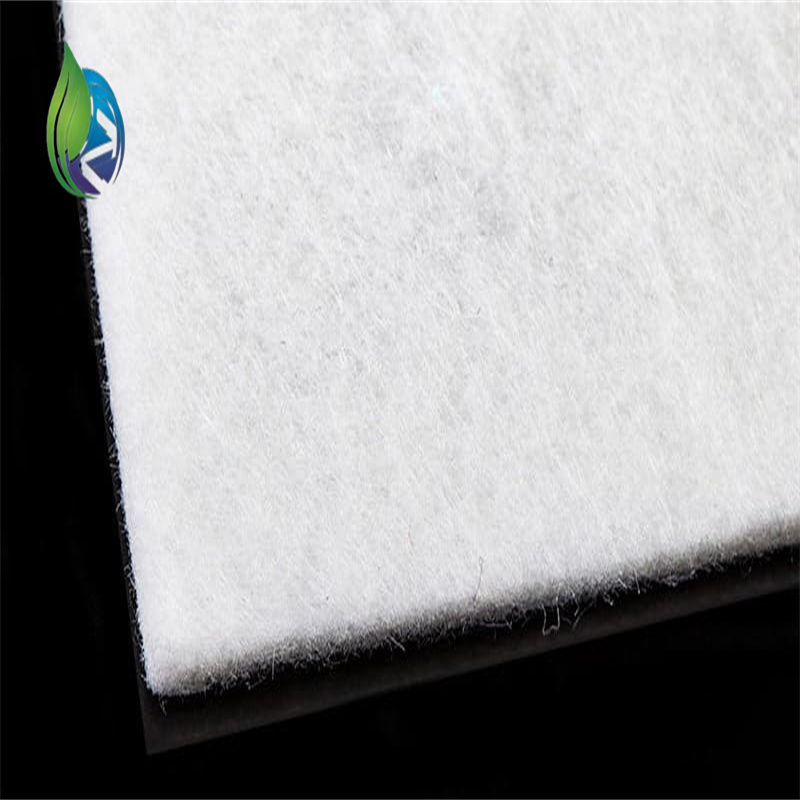

Structure and Material Composition

The structure of Custom Composite Geomembrane is engineered to balance impermeability, durability, and constructability.

Upper geotextile layer for cushioning and puncture resistance

Central geomembrane layer acting as the primary seepage barrier

Lower geotextile layer for filtration, friction, or protection

Optional functional layers for drainage, reinforcement, or anti-slip performance

Manufacturing Process

Custom Composite Geomembrane manufacturing emphasizes precision bonding and performance consistency.

Selection of polymer resin and geotextile specifications based on design

Extrusion or calendering of geomembrane sheets

Nonwoven geotextile production and surface preparation

Thermal lamination or hot-melt bonding of layers

Online thickness, peel strength, and surface inspection

Cooling, trimming, roll formation, and quality testing

Industry Comparison

| Material Type | Design Flexibility | Protection Level | Construction Adaptability | Typical Applications |

|---|---|---|---|---|

| Custom Composite Geomembrane | Very High | High | High | Dams, landfills, canals |

| Single Geomembrane | Low | Low | Moderate | Waste containment |

| Geosynthetic Clay Liner | Moderate | Moderate | Moderate | Landfill liners |

| Concrete Lining | Low | High | Low | Hydraulic structures |

Application Scenarios

Custom Composite Geomembrane is selected by distributors, EPC contractors, and engineering consultants for projects with non-standard requirements.

Reservoirs, dams, and embankments

Landfill bottom liners and covers

Mining tailings storage facilities

Irrigation canals and water conveyance systems

Industrial wastewater and containment ponds

Core Pain Points and Engineering Solutions

Complex ground conditions: Layered design improves stress distribution

Puncture and damage risk: Geotextile layers provide effective protection

Seepage control reliability: Continuous geomembrane ensures impermeability

Construction efficiency: Integrated composite reduces installation steps

Risk Warnings and Mitigation Recommendations

Ensure compatibility of bonding materials under site temperatures

Control welding parameters during field seam joining

Protect exposed geomembrane edges from UV exposure

Conduct peel strength and seam integrity testing on site

Procurement and Selection Guide

Clarify hydraulic pressure and seepage control requirements

Define mechanical load and puncture risk conditions

Select geomembrane polymer based on chemical exposure

Determine geotextile mass according to subgrade conditions

Request project-specific technical datasheets and test reports

Evaluate supplier customization capability and project experience

Engineering Case Example

In a municipal landfill expansion project, a Custom Composite Geomembrane consisting of a 1.0 mm HDPE core with double-sided 500 g/m² nonwoven geotextile was installed. The system improved puncture resistance, reduced installation damage, and met long-term seepage control requirements under variable settlement conditions.

Frequently Asked Questions

What makes it “custom”? Layer type, thickness, and bonding are project-specific.

Is it suitable for high water pressure? Yes, when designed accordingly.

Does it replace separate geotextile layers? Often, yes.

Can it be welded on site? The geomembrane core is weldable.

Is it chemical resistant? Depends on selected geomembrane polymer.

What service life can be expected? Typically 20–30 years.

Is slope installation possible? Yes, with anchoring design.

How is quality verified? Peel, tensile, and permeability tests.

Can dimensions be customized? Yes, roll width and length are adjustable.

Is third-party inspection recommended? Yes for critical infrastructure projects.

Call to Action

For project-specific quotations, technical documentation, or engineering samples of Custom Composite Geomembrane, please submit your design requirements for professional evaluation and procurement support.

E-E-A-T Author Credentials

This article is authored by geotechnical and materials engineers with extensive experience in geosynthetics, hydraulic engineering, and environmental containment systems. All technical content is based on established engineering standards, laboratory-tested material data, and verified field applications.