Geomembrane Hdpe Pond Lining

Engineering-Oriented Production Steps

Selection and formulation of high-purity HDPE resin

High-temperature extrusion via flat-die or blown-film systems

Automated thickness control and surface calibration

Optional texturing for enhanced friction performance

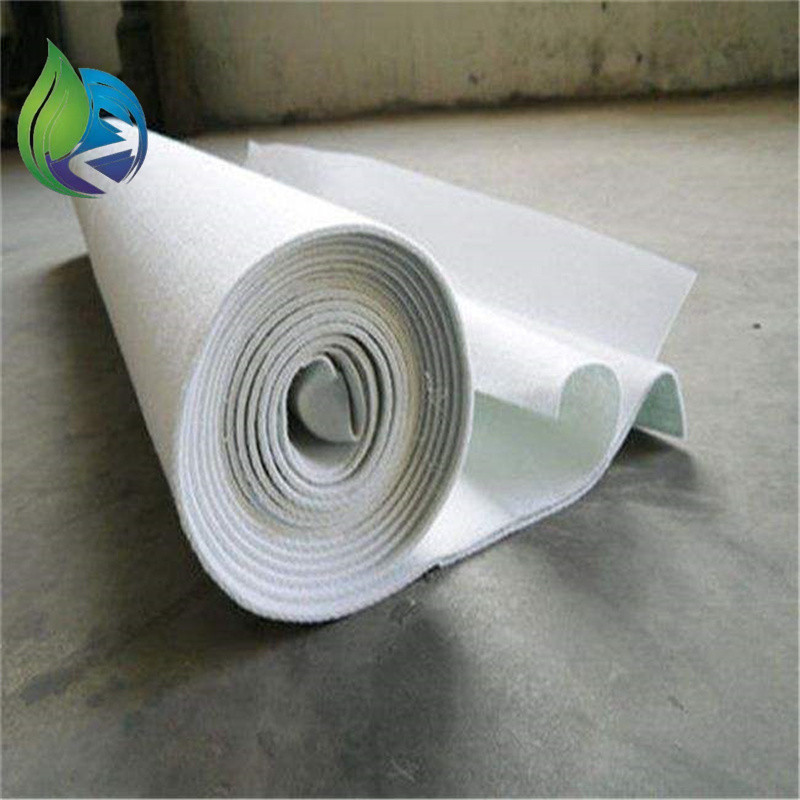

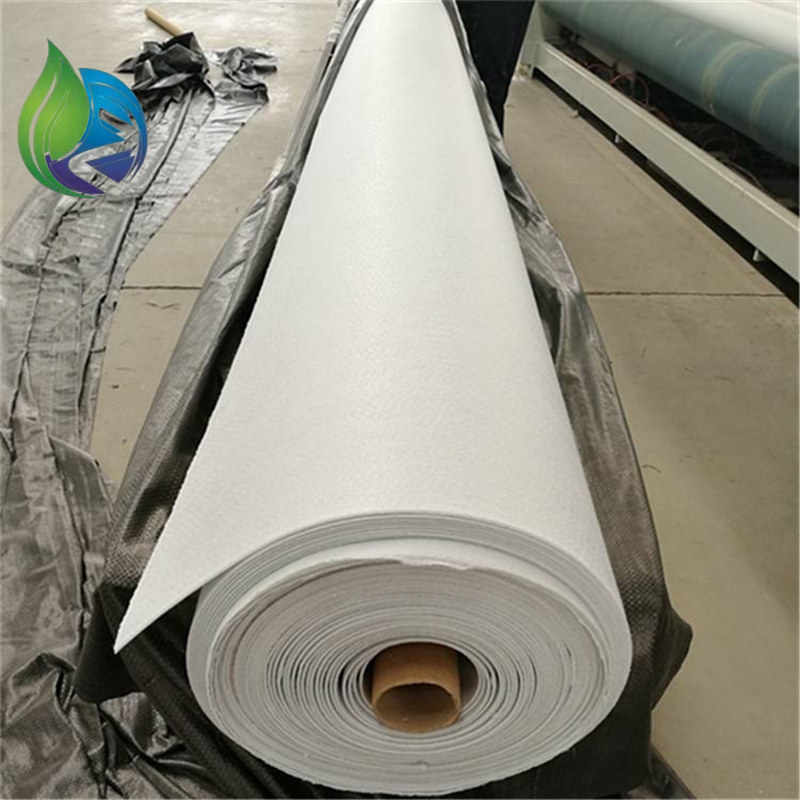

Controlled cooling and roll forming

Laboratory testing and quality inspection

Core equipment: HDPE extrusion lines, thickness scanners, tensile testing machines, carbon black dispersion analyzers.

Key process controls: Thickness tolerance, additive dispersion uniformity, surface integrity.

Product Definition

Geomembrane HDPE pond lining is a high-density polyethylene impermeable liner system designed to prevent water leakage, soil contamination, and structural erosion in engineered ponds and reservoirs. It delivers long-term hydraulic control, chemical resistance, and mechanical stability for aquaculture, water storage, and environmental engineering projects.

Technical Parameters and Specifications

Engineering-grade geomembrane HDPE pond lining must comply with standardized physical and durability requirements to ensure reliable performance under varying hydraulic and environmental conditions.

Material: High Density Polyethylene (HDPE)

Standard thickness: 0.5 mm, 0.75 mm, 1.0 mm, 1.5 mm, 2.0 mm

Sheet width: 4.0–8.0 m

Density: ≥0.94 g/cm³

Tensile strength at yield: ≥15 MPa

Elongation at break: ≥700%

Puncture resistance: ≥480 N

Carbon black content: 2.0%–3.0%

Oxidative induction time (OIT): ≥100 min

Service temperature: -40°C to +60°C

Expected service life: 30–50 years

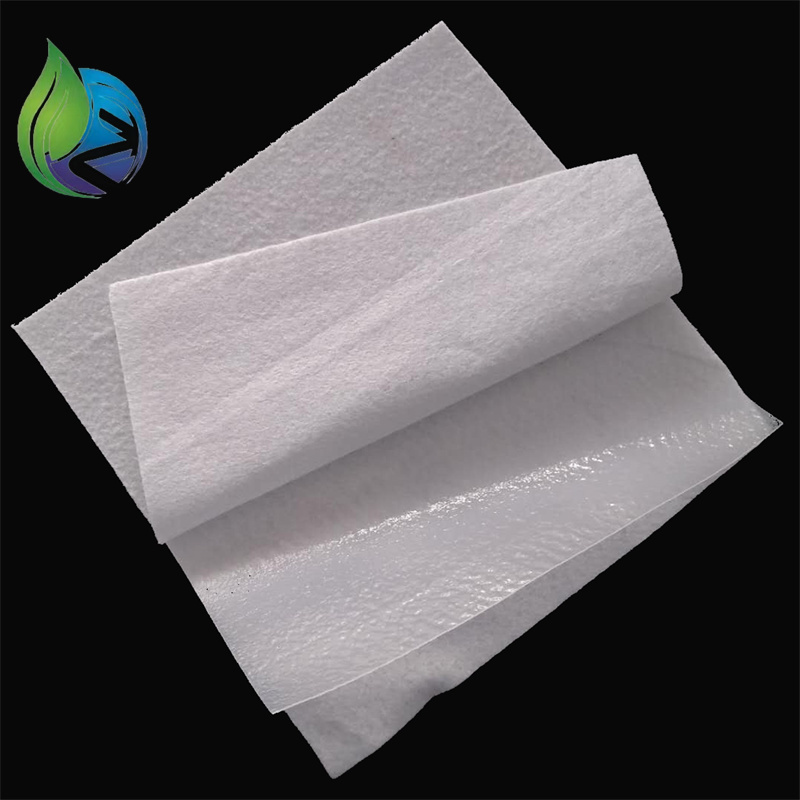

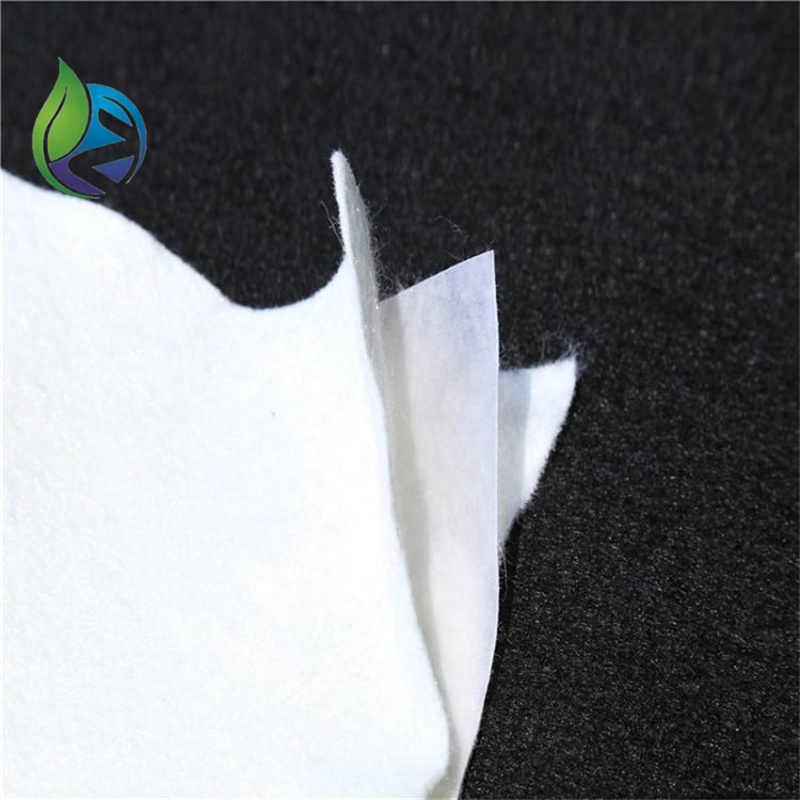

Structure and Material Composition

Geomembrane HDPE pond lining is a homogeneous polymer barrier engineered for impermeability and environmental durability.

HDPE polymer matrix: Provides impermeability and mechanical strength

Carbon black: Enhances UV resistance and aging stability

Antioxidants: Protect against thermal and oxidative degradation

Surface finish: Smooth or textured for slope stability

Manufacturing Process

Engineering-Oriented Production Steps

Selection and formulation of high-purity HDPE resin

High-temperature extrusion via flat-die or blown-film systems

Automated thickness control and surface calibration

Optional texturing for enhanced friction performance

Controlled cooling and roll forming

Laboratory testing and quality inspection

Core equipment: HDPE extrusion lines, thickness scanners, tensile testing machines, carbon black dispersion analyzers.

Key process controls: Thickness tolerance, additive dispersion uniformity, surface integrity.

Industry Comparison

| Lining Material | Impermeability | Chemical Resistance | Installation Efficiency | Lifecycle Cost |

|---|---|---|---|---|

| HDPE Geomembrane Pond Lining | Very High | Excellent | High | Low |

| LDPE Liner | High | Good | High | Medium |

| Clay Lining | Medium | Low | Low | High |

| Concrete Pond Lining | Medium | Medium | Low | High |

Application Scenarios

Geomembrane HDPE pond lining is widely used in engineered water containment systems across multiple industries.

Aquaculture ponds: Fish and shrimp farming operations

Water storage reservoirs: Agricultural and industrial water supply

Wastewater treatment ponds: Effluent and sludge containment

Mining ponds: Process water and tailings management

EPC water infrastructure projects: Integrated pond and reservoir systems

Core Pain Points and Engineering Solutions

Water leakage and loss: Continuous HDPE liner ensures near-zero permeability

Soil erosion and contamination: Effective isolation between water and subgrade

Structural deformation: High elongation accommodates settlement

High maintenance costs: Long service life reduces operational expenditure

Risk Warnings and Mitigation Recommendations

Inadequate subgrade preparation may cause puncture damage

Poor welding quality can create leakage paths

Extended UV exposure before covering may accelerate aging

Improper anchoring can result in liner uplift

Procurement and Selection Guide

Define pond function and hydraulic requirements

Select appropriate liner thickness based on water depth

Choose smooth or textured surface according to slope design

Specify welding method and seam testing requirements

Ensure compliance with ASTM, ISO, or EN standards

Evaluate supplier quality control and project references

Plan logistics, installation schedule, and on-site protection

Engineering Case Example

In a commercial aquaculture project, a 1.0 mm geomembrane HDPE pond lining system was installed over a compacted sand foundation with protective geotextile. Hot wedge welding and vacuum seam testing were applied. The pond achieved zero leakage performance and stable water quality over multiple production cycles.

FAQ

What thickness is commonly used for pond lining? 0.75–1.5 mm depending on depth.

Is HDPE geomembrane safe for aquaculture? Yes, it is non-toxic and inert.

How are seams tested? Vacuum box or air pressure testing.

Can it withstand UV exposure? Yes, with carbon black stabilization.

Does it resist chemicals? Excellent resistance to most acids and alkalis.

What is the expected lifespan? 30–50 years with proper installation.

Is textured surface necessary? Recommended for steep slopes.

Can it be repaired if damaged? Yes, by extrusion or patch welding.

Is third-party testing required? Recommended for large projects.

Can it be installed in cold climates? Yes, within specified temperature limits.

CTA

For geomembrane HDPE pond lining technical datasheets, engineering specifications, pricing information, or project-based samples, please submit a formal request for quotation or technical documentation.

E-E-A-T Author Credentials

This article is written by a geosynthetics engineering professional with over 15 years of experience in HDPE geomembrane manufacturing, design, and application for aquaculture, water storage, and environmental engineering projects worldwide.