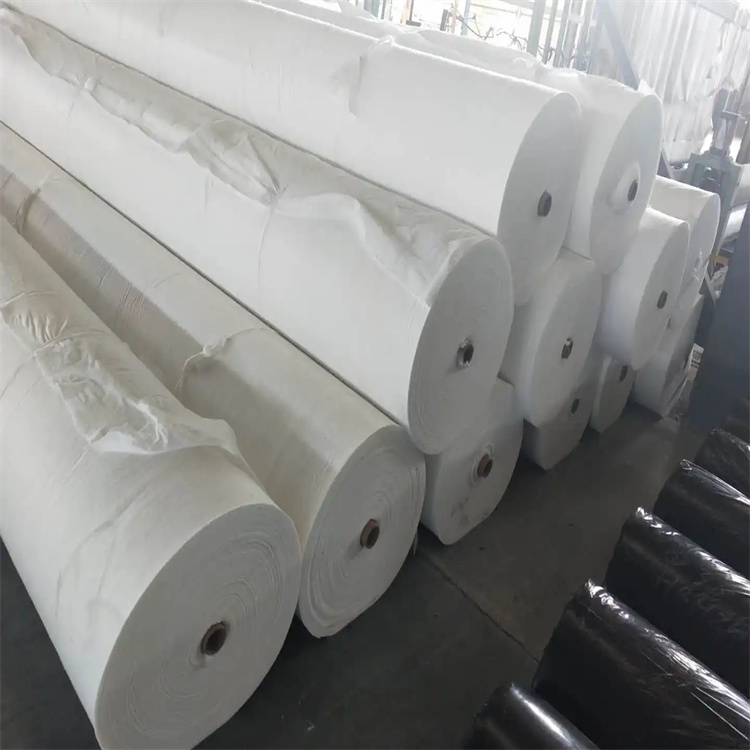

Filament Geotextile for Soil Protection

Filament geotextile has good mechanical function, good water permeability, corrosion resistance, anti-aging, reverse filtration, drainage, protection, stability, reinforcement and other functions.

Support bulk ordering with favorable prices.

Support ODM/OEM.

The factory has stock and fast delivery.

Delivery Time: 10-20 working days

Minimum Order Quantity: 300 square meters

Payment Term: 30% T/T Deposit, 70% T/T Before Shipping

When it comes to effective soil protection, few solutions offer the durability, flexibility, and cost-efficiency of filament geotextile. Whether you’re working on slope stabilization, road construction, coastal defense, or landfill engineering, using filament geotextile for soil protection ensures lasting performance in even the harshest conditions.

In this comprehensive guide, we explore how filament geotextile works, why it's the top choice among civil engineers, and how to select the right type for your project.

What Is Filament Geotextile?

Filament geotextile is a high-strength, nonwoven fabric made from continuous polyester or polypropylene filaments, bonded together using a needle-punching process. The result is a tough, permeable material capable of handling pressure, resisting UV damage, and separating layers of soil without deteriorating over time.

Used widely in geotechnical and environmental engineering, filament geotextile for soil protection provides four critical functions:

Filtration

Separation

Reinforcement

Drainage

Why Use Filament Geotextile for Soil Protection?

✅ 1. High Tensile Strength & Puncture Resistance

Filament geotextile maintains its integrity under heavy loads and abrasive materials, making it ideal for highway embankments, railways, or construction pads.

✅ 2. Excellent Permeability

Its porous structure allows water to pass through while preventing soil erosion, making it effective for drainage layers and slope stability.

✅ 3. Long Lifespan

Thanks to UV resistance, chemical stability, and biological inertness, filament geotextile can last 50+ years underground with minimal maintenance.

✅ 4. Versatility Across Soil Types

Whether dealing with soft clay, coarse gravel, or acidic soil, filament geotextile adapts and performs consistently without breakdown.

Common Applications of Filament Geotextile for Soil Protection

Highway and Railway Subgrade Reinforcement

Riverbank and Coastal Erosion Control

Slope and Embankment Stabilization

Landfill and Leachate Separation

Underground Drainage Systems

Retaining Wall Backfill Support

? “We used filament geotextile for stabilizing a flood-prone slope, and after two rainy seasons, no erosion at all — impressive material.”

— Liam G., Civil Engineer, Ireland

? “It’s breathable, tough, and easy to work with. Installed over 20,000 sqm with zero tearing or failure during compaction.”

— Chen Wei, Site Manager, Malaysia

How to Choose the Right Filament Geotextile

When selecting filament geotextile for soil protection, consider the following factors:

? Weight (gsm)

Ranges from 150gsm to 800gsm, where higher weight offers greater strength and durability for high-load projects.

? Tensile Strength

Ensure compatibility with expected ground pressure and load — often measured in kN/m (kilonewton per meter).

? Permeability Rate

Critical for filtration and drainage applications; ensure it meets the hydraulic conductivity requirements of your site.

? UV Resistance

For surface-level or exposed applications, opt for UV-stabilized variants to avoid material degradation.

? Roll Size

Check that your supplier offers custom roll dimensions for easier installation and minimal material waste.

Comparison: Filament vs. Staple Fiber Geotextile

| Property | Filament Geotextile | Staple Fiber Geotextile |

|---|---|---|

| Fiber Type | Continuous filament | Short-cut fibers |

| Strength | High | Moderate |

| Lifespan | 50+ years | 20–30 years |

| Soil Compatibility | Versatile | Less stable in coarse soils |

| Cost | Slightly higher | More economical upfront |

Environmental Benefits

Choosing filament geotextile for soil protection supports sustainable engineering practices:

♻️ Reduces soil displacement and erosion

? Supports groundwater recharge by filtering runoff

? Encourages vegetation growth on stabilized slopes

? Requires fewer repairs and replacements = less carbon footprint

Frequently Asked Questions

Q: Is filament geotextile suitable for coastal protection?

A: Absolutely. Its high tensile strength and resistance to chemical corrosion make it ideal for seawalls and breakwaters.

Q: Can it be used under concrete structures?

A: Yes, it's often placed beneath concrete pads to prevent soil mixing and ensure uniform support.

Q: How is it installed?

A: Installation is straightforward: roll out the geotextile, overlap by 30–50cm, secure with U-pins or sandbags, and cover with soil or aggregate.

Final Thoughts

When you're planning for long-term performance, cost efficiency, and environmental responsibility, filament geotextile for soil protection is the professional-grade solution you can count on. From flood control to high-load infrastructure, it protects your ground and strengthens your foundation — literally.