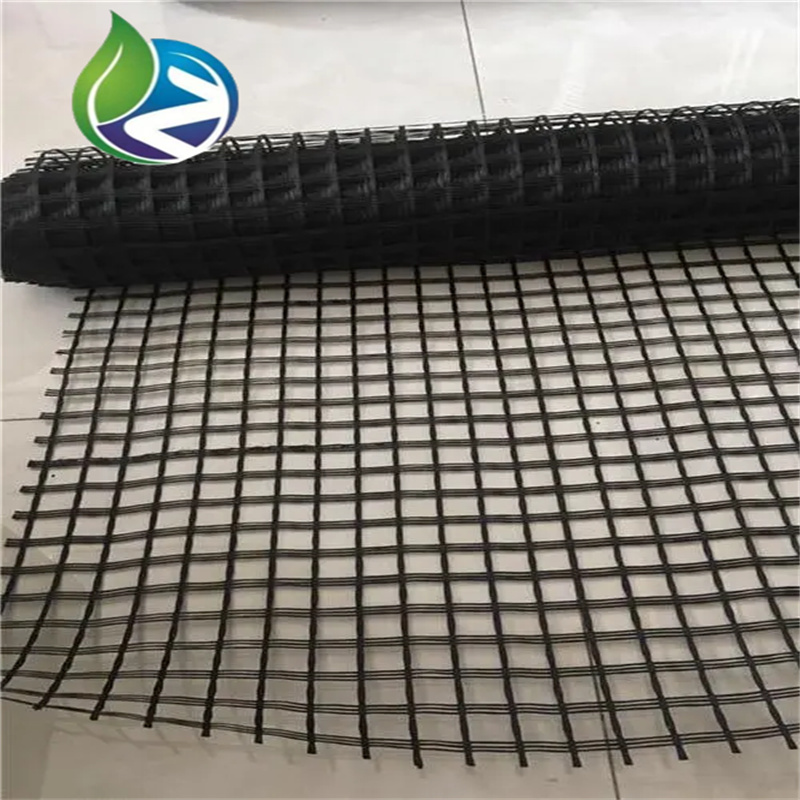

High tensile strength glass fiber grille

Glass fiber geoglass is an excellent geosynthetic material used for pavement reinforcement. old road reinforcement. and reinforcement of roadbed and soft soil foundation.It has high tensile strength and low elongation in both warp and weft directions. and has excellent properties such as high temperature resistance. low cold resistance. aging resistance and corrosion resistance.

In modern civil engineering and road construction, one material stands out for its superior reinforcement capabilities—high tensile strength glass fiber grille. As infrastructure demands grow and environmental conditions become more challenging, using durable, high-performance materials is no longer optional—it’s essential.

This article explores why the high tensile strength glass fiber grille is the preferred choice for reinforcing asphalt pavements, base layers, and roadbeds. We'll cover its key benefits, applications, technical features, and how it outperforms traditional reinforcement solutions.

What Is a High Tensile Strength Glass Fiber Grille?

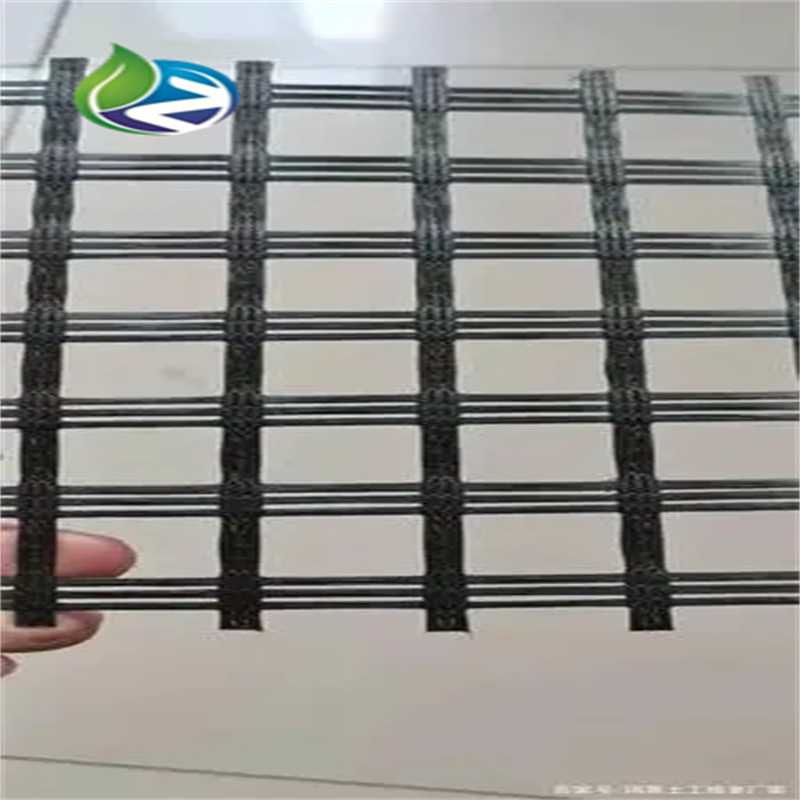

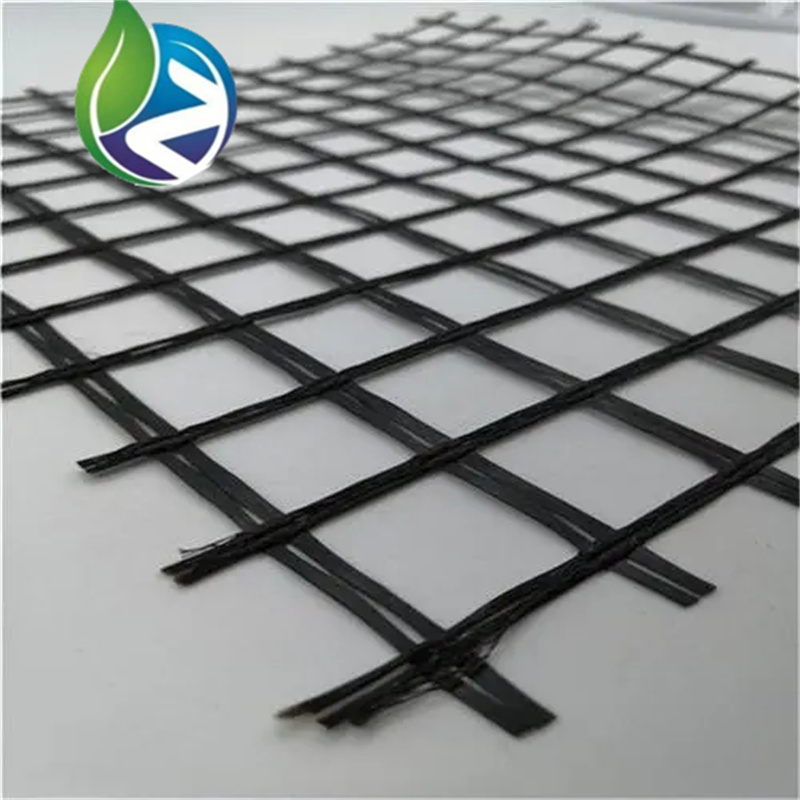

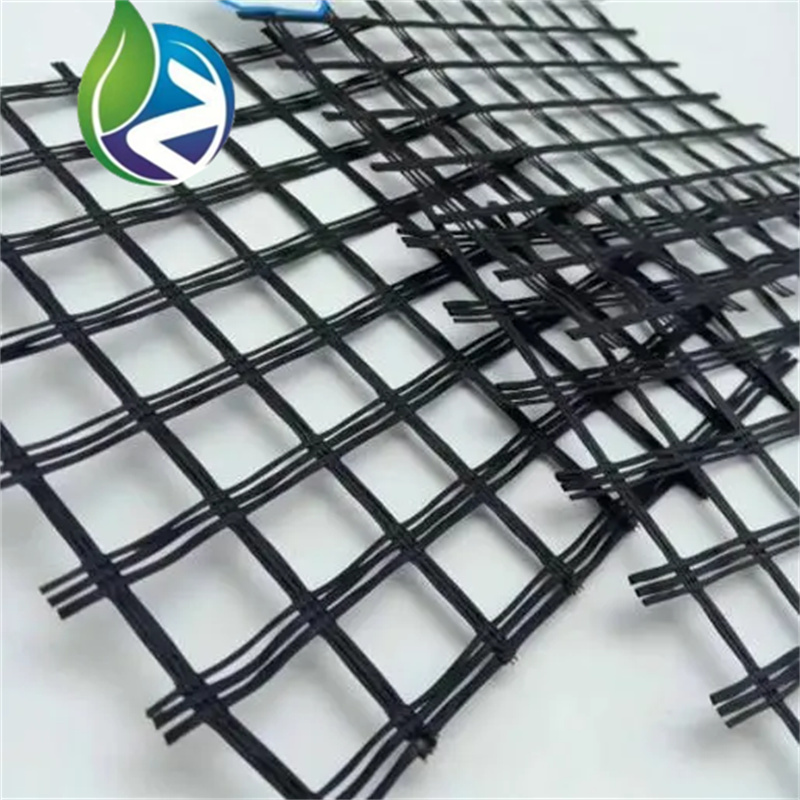

A high tensile strength glass fiber grille is a geosynthetic material made from alkali-resistant glass fibers, coated with bitumen or polymer-based compounds to improve adhesion and durability. This mesh-like grille provides exceptional tensile strength in both warp and weft directions, enabling it to resist cracking, deformation, and rutting under heavy traffic and temperature fluctuations.

Engineered for optimal performance in extreme conditions, the high tensile strength glass fiber grille is particularly suitable for asphalt overlay reinforcement, making roads last longer and perform better.

Benefits of High Tensile Strength Glass Fiber Grille

✅ Exceptional Tensile Strength

The defining feature of a high tensile strength glass fiber grille is its tensile strength—often reaching up to 100–200 kN/m. This high capacity ensures excellent resistance against crack propagation and pavement fatigue.

✅ Enhanced Pavement Life

By preventing reflective cracking and distributing loads evenly, high tensile strength glass fiber grille extends the life of both asphalt and concrete pavements.

✅ Excellent Heat Resistance

Unlike plastic geogrids, glass fiber grilles can withstand high asphalt laying temperatures without deformation, making them perfect for hot-mix paving operations.

✅ Superior Bonding with Asphalt

Bitumen-coated glass fiber grilles adhere seamlessly to asphalt layers, preventing slippage and enhancing structural performance.

✅ Lightweight & Easy Installation

Despite their high strength, these grilles are lightweight, flexible, and easy to cut and install—reducing labor costs and construction time.

Applications of High Tensile Strength Glass Fiber Grille

High tensile strength glass fiber grille is widely used in:

Highway and expressway overlays

Airport runways and taxiways

Urban road rehabilitation

Bridge decks

Parking lots

Concrete reinforcement underlayers

Its ability to control cracking and reinforce surfaces under heavy loads makes it indispensable in transport infrastructure projects.

Technical Specifications (Typical)

Material: Alkali-free glass fiber

Tensile Strength: 50–200 kN/m

Elongation at Break: ≤3%

Coating: Bitumen or polymer for enhanced adhesion

Aperture Size: 12.5 × 12.5 mm or customized

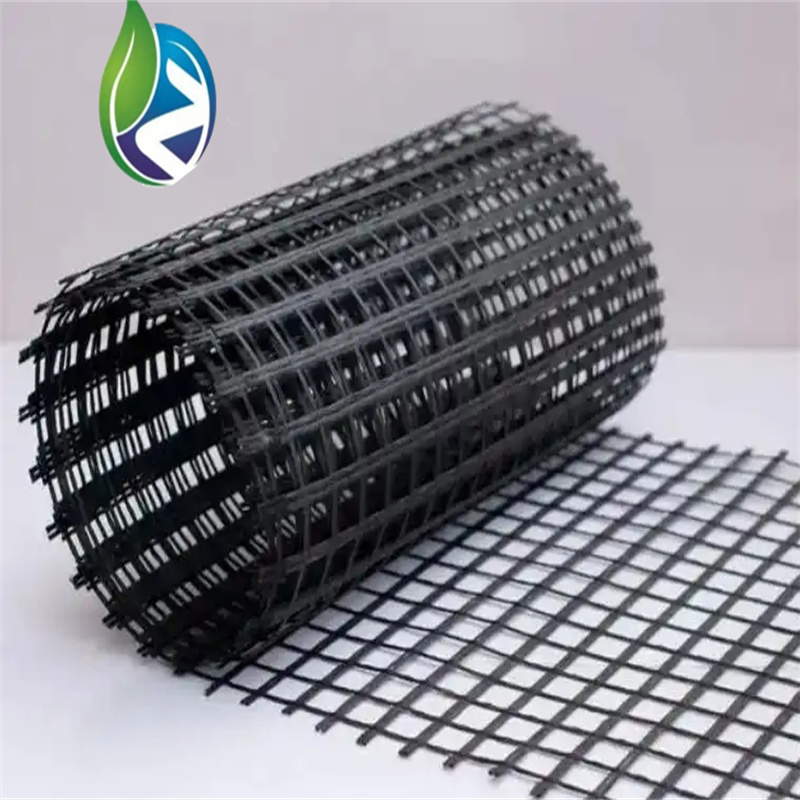

Roll Width: 1 to 6 meters

Roll Length: 50 to 200 meters

Always ensure the high tensile strength glass fiber grille you select meets local or international standards like ASTM D6637 or EN ISO 10319.

Why Choose High Tensile Strength Glass Fiber Grille Over Traditional Methods?

| Feature | Traditional Geogrid | Glass Fiber Grille |

|---|---|---|

| Tensile Strength | Moderate (up to 100 kN/m) | Very High (up to 200 kN/m) |

| Heat Resistance | Moderate | Excellent |

| Crack Resistance | Moderate | Outstanding |

| Installation Convenience | Good | Excellent |

| Cost-Effectiveness (Long-term) | Moderate | High due to lifespan extension |

The high tensile strength glass fiber grille clearly outperforms older methods in critical structural and performance metrics.

Installation Guide: Best Practices

Prepare the Base: Make sure the surface is clean and dry.

Unroll and Align: Lay the glass fiber grille smoothly without wrinkles or overlaps.

Adhesive Application: Use bituminous tack coat for better bonding.

Overlay Laying: Apply the asphalt overlay directly on top, compact properly.

Proper installation ensures maximum performance and longevity of your high tensile strength glass fiber grille system.

Conclusion: Build Stronger Roads That Last

Choosing a high tensile strength glass fiber grille for your next pavement or foundation project is a smart investment in durability, safety, and long-term cost savings. With unmatched crack resistance, heat stability, and tensile strength, it’s the superior choice for engineers and contractors aiming to build roads that withstand the test of time and traffic.

If you’re looking for certified, high-performance high tensile strength glass fiber grille, contact our technical team today for expert consultation, samples, and pricing.

Key Features of High Tensile Strength Glass Fiber Grilles

High Tensile Strength

Glass fiber grilles are designed to handle significant tensile forces without failure. Their high tensile strength makes them suitable for reinforcing concrete, roads, railways, and other infrastructure where the load-bearing capacity is critical. The fibers within the grille provide reinforcement that helps distribute stresses evenly across the surface, minimizing the risk of cracking or failure under pressure.Corrosion Resistance

One of the standout features of high tensile strength glass fiber grilles is their exceptional resistance to corrosion. Unlike traditional steel reinforcements, which can corrode when exposed to moisture and harsh chemicals, glass fibers are highly resistant to environmental factors such as water, salts, and alkalis. This makes glass fiber grilles ideal for use in areas with high humidity, coastal environments, or locations prone to exposure to chemicals.Lightweight and Easy to Handle

Glass fiber grilles are much lighter than steel reinforcements, making them easier to transport, handle, and install. The reduced weight helps minimize labor costs and improves the overall efficiency of construction projects. Despite being lightweight, they retain their structural integrity, providing excellent performance even under high-stress conditions.Durability and Longevity

Glass fiber is known for its long service life. Grilles made from high-tensile glass fiber are resistant to UV radiation, chemical degradation, and other environmental factors that typically lead to material wear and tear. This durability ensures that the grilles maintain their structural properties over time, even in the most challenging environments.Flexibility in Application

High tensile strength glass fiber grilles can be used in a wide range of applications, including road reinforcement, railway tracks, retaining walls, soil stabilization, and construction of drainage systems. They are also used in pavements, airport runways, and even in marine structures. Their versatility makes them suitable for both large-scale infrastructure projects and smaller, specialized applications.