Protective Light Plate

Learn how protective light plates enhance safety and durability in construction and industrial applications. Discover benefits, trends, and key considerations in choosing the right protective plates for your project.

Protective Light Plates: Essential Material for Durable and Safe Construction

Introduction

In the world of construction and industrial applications, materials that provide safety, durability, and ease of use are paramount. One such material that is gaining significant attention is the protective light plate. These plates are engineered to safeguard various structures and systems from environmental elements, wear and tear, and physical impact.

Whether you're involved in construction, machinery protection, or industrial applications, understanding the benefits and applications of protective light plates is essential. In this article, we explore the role of these plates, the materials used, and the market trends driving their popularity.

What is a Protective Light Plate?

Definition and Purpose

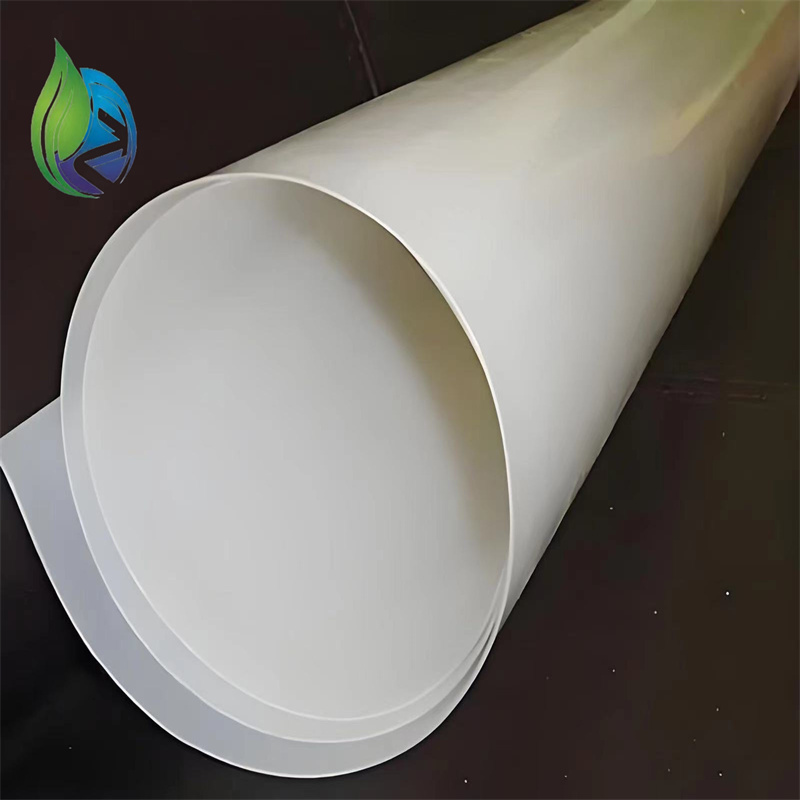

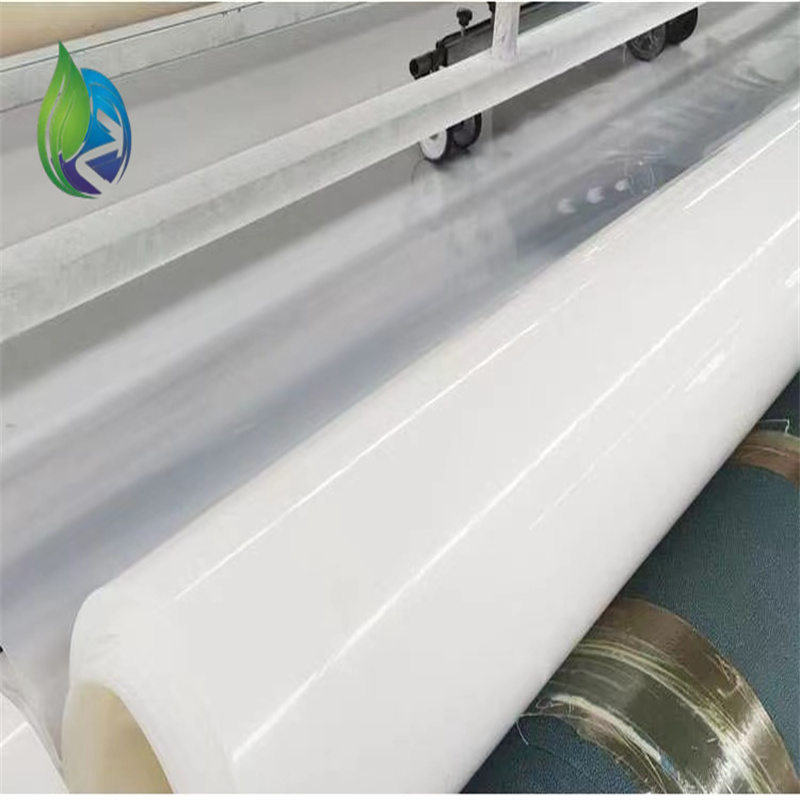

A protective light plate is a type of protective sheeting made from lightweight yet durable materials designed to shield surfaces from damage. These plates are used in various sectors, including construction, transportation, electronics, and machinery, to provide an extra layer of protection against external forces such as impact, abrasion, and environmental exposure.

The main purpose of protective light plates is to preserve the integrity of equipment and structures while minimizing the maintenance costs associated with damage. By acting as a barrier, these plates absorb external stress and prevent direct contact with sensitive surfaces, thereby extending the lifespan of products and equipment.

Types of Protective Light Plates

1. Polycarbonate Protective Plates

Polycarbonate is one of the most common materials used for protective light plates due to its exceptional strength and resistance to impact. These plates offer high transparency, making them ideal for applications where visibility is important, such as machinery guards and display screens.

2. Acrylic Protective Plates

Acrylic plates are another popular choice due to their lightweight nature and clarity. They are often used in signage, protective barriers, and decorative applications. Acrylic plates are not as impact-resistant as polycarbonate but offer great weather resistance and UV protection, making them suitable for outdoor applications.

3. Aluminum Composite Plates

For industrial applications requiring a stronger protective layer, aluminum composite plates are ideal. These plates consist of a metal core and a plastic outer layer, providing enhanced durability and strength. Aluminum composite plates are often used in exterior cladding, architectural design, and vehicle protection.

4. Fiberglass Reinforced Plates

Fiberglass plates are known for their strength-to-weight ratio and resistance to corrosion. These plates are commonly used in environments where heavy-duty protection is necessary, such as in marine applications or chemical processing plants.

Benefits of Protective Light Plates

1. Durability and Longevity

Protective light plates are designed to withstand physical impacts, weather conditions, and other environmental factors. By providing a durable shield against external damage, these plates can significantly extend the lifespan of underlying structures or equipment.

For example, polycarbonate light plates are up to 250 times stronger than glass, making them highly effective at protecting machinery and infrastructure in high-traffic areas or high-risk environments.

2. Cost-Effective Solution

While the upfront cost of installing protective light plates may seem high, they provide long-term cost savings by reducing the need for frequent repairs and replacements. By absorbing impact and preventing direct damage, protective plates can minimize maintenance costs and prevent downtime.

3. Lightweight and Easy to Install

Despite their strength, most protective light plates are lightweight and easy to handle. This makes them cost-effective for installation and maintenance, especially in construction or industrial settings where time and labor costs are crucial factors.

4. Versatility and Customization

Protective light plates can be customized to suit specific needs, whether for machinery protection, wall coverings, or window shields. They can be cut, shaped, and coated to meet precise project requirements, making them suitable for a wide range of industries.

Applications of Protective Light Plates

1. Construction Industry

In construction, protective light plates are often used to shield walls, floors, and equipment from damage during construction or renovation work. They can also be used as temporary barriers to protect materials and personnel from accidents or impacts.

2. Transportation

In the transportation sector, protective plates are applied to vehicle exteriors, cargo hold areas, and trailer beds to prevent abrasion and corrosion. They are also used in trains, buses, and aircraft to protect delicate parts from external damage.

3. Electronics and Machinery

In electronics and machinery, protective light plates are used as covers for screens, displays, and control panels to prevent scratches, dirt, and moisture from damaging sensitive components.

4. Agriculture

For agriculture, protective light plates are often used as barriers in greenhouses, where they protect plants from wind, debris, and animals, while still allowing sunlight to penetrate.

Market Trends and Demand for Protective Light Plates

1. Increasing Demand in Industrial Applications

As industries worldwide continue to prioritize safety and efficiency, the demand for protective light plates has been rising. Manufacturers and construction companies are increasingly using these materials in their projects to improve worksite safety and reduce equipment maintenance costs.

2. Growing Preference for Eco-Friendly Materials

There is a growing trend towards the use of sustainable and eco-friendly materials in construction and industrial applications. Many protective light plates are now made from recyclable materials like polycarbonate and acrylic, which helps reduce the environmental impact of manufacturing and disposal.

3. Technological Advancements in Material Manufacturing

Recent technological advancements in the production of protective plates have led to the development of materials with enhanced durability, UV resistance, and impact strength. Manufacturers are now able to offer protective light plates that are even more resistant to weather, chemicals, and other environmental stresses.

Frequently Asked Questions (FAQ)

1. What are protective light plates used for?

Protective light plates are used to shield surfaces, machinery, and equipment from damage caused by physical impacts, weather, and other environmental elements. They are commonly used in construction, electronics, transportation, and agriculture.

2. How long do protective light plates last?

The lifespan of protective light plates varies depending on the material and environmental conditions. High-quality plates can last for 10–20 years or longer with proper maintenance, offering long-term protection.

3. Are protective light plates resistant to UV rays?

Yes, many polycarbonate and acrylic protective plates are designed to provide UV resistance, ensuring that they do not degrade or discolor when exposed to sunlight over time.

4. Can protective light plates be customized?

Yes, protective light plates can be customized in terms of size, shape, and material thickness to suit specific applications. Some manufacturers also offer coatings for enhanced resistance to environmental factors.

Conclusion and Call to Action

Protective light plates are a crucial material for industries looking to enhance safety, durability, and performance in construction and industrial applications. Whether you're protecting machinery, infrastructure, or sensitive components, these plates provide a cost-effective solution to prevent damage and reduce maintenance costs.

If you're looking to source high-quality protective light plates for your project, we offer a range of materials designed to meet your specific needs. Contact us today to learn more about how our protective plates can help you safeguard your construction or industrial assets.