High Performance HDPE Geomembrane

Manufacturing Process

Industrial production of High Performance HDPE Geomembrane follows controlled engineering processes:

Raw HDPE resin drying and automated gravimetric feeding

Twin-screw extrusion and melt homogenization

Flat die or blown film sheet extrusion

Online thickness control using laser scanning systems

Surface texturing via precision embossing rollers

Cooling through calibrated water bath or air cooling systems

Automatic trimming, edge alignment, and roll winding

Mechanical and visual quality inspection before packaging

Product Definition

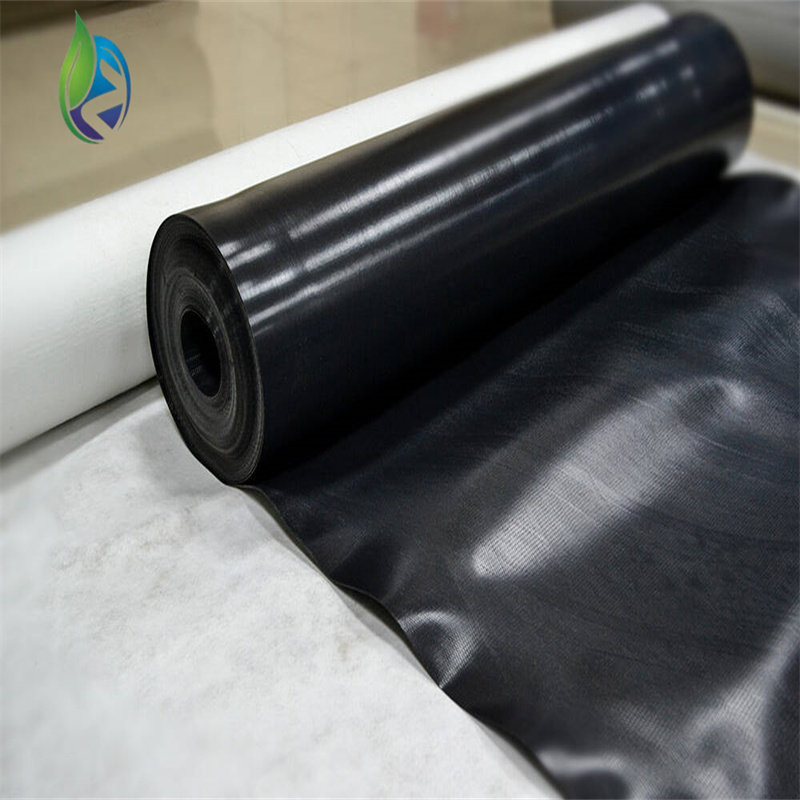

High Performance HDPE Geomembrane is an impermeable geosynthetic liner manufactured from high-density polyethylene resin, engineered to deliver superior tensile strength, chemical resistance, and long-term durability for critical containment applications in environmental, mining, and hydraulic engineering projects.

Technical Parameters and Specifications

Typical engineering parameters for High Performance HDPE Geomembrane used in large-scale projects:

Base polymer: High-density polyethylene (HDPE)

Thickness range: 0.75 mm – 3.0 mm

Density: 0.94 – 0.96 g/cm³

Tensile strength at yield: 15 – 25 MPa

Tensile strength at break: 20 – 35 MPa

Elongation at break: 600% – 800%

Puncture resistance: 600 – 1500 N

Tear resistance: 200 – 450 N

Carbon black content: 2.0% – 3.0%

Oxidative induction time (OIT): ≥100 minutes (standard test conditions)

Service temperature range: -40°C to +60°C

Expected design life: 20 – 30 years in buried conditions

Structure and Material Composition

The structural design of High Performance HDPE Geomembrane typically includes:

Upper surface layer: Smooth or textured HDPE protective skin

Core layer: High crystallinity HDPE polymer matrix

Stabilizer system: Carbon black and antioxidant additives

Optional reinforcement: Integrated fabric or scrim for composite variants

Bottom functional layer: Anti-slip texture for slope stability

Manufacturing Process

Industrial production of High Performance HDPE Geomembrane follows controlled engineering processes:

Raw HDPE resin drying and automated gravimetric feeding

Twin-screw extrusion and melt homogenization

Flat die or blown film sheet extrusion

Online thickness control using laser scanning systems

Surface texturing via precision embossing rollers

Cooling through calibrated water bath or air cooling systems

Automatic trimming, edge alignment, and roll winding

Mechanical and visual quality inspection before packaging

Industry Comparison

| Material Type | Tensile Strength | Chemical Resistance | Service Life | Maintenance Frequency |

|---|---|---|---|---|

| High Performance HDPE Geomembrane | High | Excellent | 20–30 Years | Low |

| Standard HDPE Geomembrane | Medium | Good | 15–20 Years | Medium |

| LLDPE Geomembrane | Medium | Good | 12–18 Years | Medium |

| PVC Liner | Low | Fair | 10–15 Years | High |

Application Scenarios

High Performance HDPE Geomembrane is widely specified by:

Material distributors supplying geosynthetics to infrastructure projects

EPC contractors managing large-scale containment systems

Civil engineering firms executing landfill and mining facilities

Industrial developers building wastewater and chemical storage ponds

Typical engineering applications include landfill liners, leachate collection systems, tailings storage facilities, water reservoirs, canals, and industrial retention basins.

Core Pain Points and Solutions

Subgrade differential settlement causing liner stress — addressed by high elongation HDPE formulations

Puncture from sharp aggregates — mitigated using higher thickness and geotextile cushioning layers

Premature oxidation — reduced through antioxidant and carbon black stabilization systems

Seam leakage risk — controlled by automated hot wedge welding and non-destructive seam testing

Risk Warnings and Mitigation Recommendations

Uneven base preparation may create stress concentration — perform fine grading and compaction

Incorrect welding temperature weakens seams — use calibrated welding equipment

Long-term UV exposure during storage may degrade material — store under UV-protective covers

Chemical incompatibility may reduce service life — conduct chemical resistance verification before installation

Procurement and Selection Guide

Define hydraulic containment and mechanical stress requirements

Confirm thickness and density according to design codes

Review tensile, puncture, and OIT test certificates

Verify manufacturer quality management and traceability systems

Assess field welding compatibility with available equipment

Request project-specific samples for laboratory validation

Plan long-term inspection and maintenance protocols

Engineering Case Example

In a municipal landfill expansion project, a 2.0 mm High Performance HDPE Geomembrane was installed over a compacted clay base and nonwoven geotextile. The project covered approximately 52,000 m² and utilized dual-track hot wedge welding. Post-installation testing confirmed stable seam integrity and resistance to long-term settlement under waste loading.

FAQ

Q1: What thickness is commonly used in landfill projects?

A: Typically 1.5–2.0 mm.Q2: Can it withstand aggressive chemicals?

A: HDPE provides strong resistance to most acids and alkalis.Q3: What is the standard roll width?

A: Usually 5–8 meters.Q4: How are seams tested?

A: By air pressure and vacuum box methods.Q5: Is it suitable for exposed applications?

A: Yes, with UV-stabilized formulations.Q6: What temperature range can it operate in?

A: -40°C to +60°C.Q7: How long can it be stored on site before installation?

A: Typically up to 12 months under covered conditions.Q8: Can it be installed on slopes?

A: Yes, textured surfaces improve slope stability.Q9: Does it require anchor trenches?

A: Yes, in most permanent installations.Q10: Which standards are applicable?

A: ASTM and ISO geosynthetics standards.

CTA – Commercial Technical Request

For project-based procurement, submit a formal request for quotation, detailed technical datasheet, and engineering-grade samples of High Performance HDPE Geomembrane through authorized technical sales channels.

E-E-A-T Author Credentials

This technical document is prepared by senior geotechnical engineers and materials experts with more than 15 years of experience in geosynthetics design, landfill engineering, and international EPC project consulting, providing authoritative guidance for professional B2B procurement teams.