Best Geomembrane Welding Machine

Geomembrane welding machine is one of many welding equipment, the main welding objects :HDPE, PE-C, PP,LDPE. Trough surface geomembrane, impermeable membrane; Mechanical and electrical integration design, small size, light weight, field operation has good operability. Double weld lap welding, high temperature control precision, high welding strength, good sealing effect, in the middle of the weld leak detection path, automatic crawling can achieve slope, vertical, upside down automatic welding.

Plastic Geomembrane Welding Machine: Precision Seam Welding for Geosynthetics

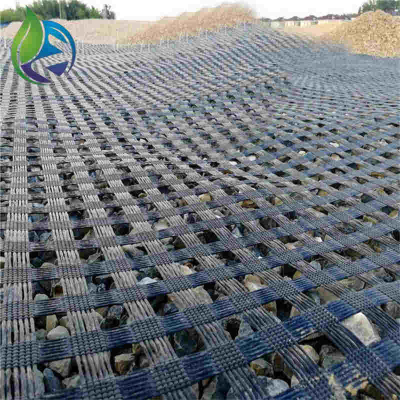

A plastic geomembrane welding machine is a specialized device engineered for the seamless and efficient joining of geomembrane sheets used in environmental, civil, and industrial applications. Designed to deliver strong, watertight welds, the plastic geomembrane welding machine is essential in projects involving landfills, ponds, canals, mining liners, and tunnel waterproofing systems.

What Is a Plastic Geomembrane Welding Machine?

A plastic geomembrane welding machine is used to join HDPE, LDPE, PVC, EVA, and other thermoplastic geomembrane materials by applying heat and pressure. These machines utilize hot wedge, hot air, or extrusion welding technologies to fuse overlapping geomembrane sheets, creating reliable and long-lasting seams.

The purpose of a plastic geomembrane welding machine is to ensure structural integrity and water impermeability across large-scale geomembrane installations. Whether working on slope linings or reservoir sealing, these machines are trusted by contractors worldwide for their durability and precision.

Key Features of Plastic Geomembrane Welding Machine

Automatic Temperature Control

Equipped with intelligent temperature regulation, the plastic geomembrane welding machine ensures optimal welding quality across varying environmental conditions.High Welding Efficiency

With speeds up to 5 meters per minute, the plastic geomembrane welding machine significantly boosts productivity on site while maintaining consistent seam strength.Durable and Lightweight Design

Engineered with aluminum alloy casings and ergonomic handles, the plastic geomembrane welding machine is both portable and resistant to harsh jobsite environments.Wide Compatibility

The plastic geomembrane welding machine is suitable for welding a wide range of plastic geomembranes, including HDPE, LDPE, PVC, and TPO.Precision Seam Control

Seam width and overlap are precisely adjustable, ensuring that every weld meets project specifications and international standards.

Applications of Plastic Geomembrane Welding Machine

The plastic geomembrane welding machine is widely used in the following areas:

Landfill Liners and Covers

Ensures leak-proof seams for hazardous waste containment and environmental protection.Aquaculture Ponds and Fish Farms

The plastic geomembrane welding machine provides secure welding in the lining of ponds, preventing water loss and contamination.Mining Industry

Welds geomembranes used in tailings dams and heap leach pads, ensuring safe containment of chemicals and leachate.Canals and Reservoirs

Used to seal irrigation canals and water storage facilities, enhancing water conservation and distribution efficiency.Tunnel Waterproofing

Plays a critical role in sealing tunnel linings to prevent water seepage and structural degradation.

In every case, the plastic geomembrane welding machine improves reliability, longevity, and safety of geomembrane installations.

Types of Plastic Geomembrane Welding Machine

There are several models and configurations of plastic geomembrane welding machine, including:

Hot Wedge Welding Machine

Ideal for thicker geomembranes; provides deep, uniform heat penetration and consistent welds.Hot Air Welding Machine

Commonly used for thinner sheets; offers fast and clean fusion with adjustable airflow.Extrusion Welding Machine

Best for corner joints, repairs, and T-welds; feeds molten plastic into seam gaps for strong bonding.

Each plastic geomembrane welding machine type is selected based on material thickness, project complexity, and welding environment.

Benefits of Using a Plastic Geomembrane Welding Machine

Strong and Reliable Welds

Guarantees consistent and durable seam strength across large areas.Time and Labor Savings

Automation and high-speed welding reduce installation time and costs.On-Site Adaptability

Operates in various terrain and weather conditions with ease.Compliance with International Standards

Seam results from the plastic geomembrane welding machine meet ASTM and ISO waterproofing and strength criteria.

Conclusion

A plastic geomembrane welding machine is a vital tool for modern geotechnical and environmental engineering projects. Whether you are lining a landfill, sealing a fish pond, or protecting a tunnel from water ingress, investing in a high-quality plastic geomembrane welding machine ensures secure, efficient, and cost-effective results.

Enhance your project’s reliability and performance with our professional-grade plastic geomembrane welding machine — the smart solution for every geomembrane welding challenge.