PET Welded Geogrid

Manufacturing Process

The production of PET Welded Geogrid follows controlled industrial procedures to ensure stable mechanical properties and long-term durability.

PET resin drying and melt extrusion into flat strips.

Precision stretching through multi-zone orientation lines.

Grid layout positioning using automated alignment frames.

Thermal or ultrasonic welding at junction nodes.

Surface coating via inline calender or dipping units.

Dimensional inspection and tensile testing before roll forming.

Product Definition

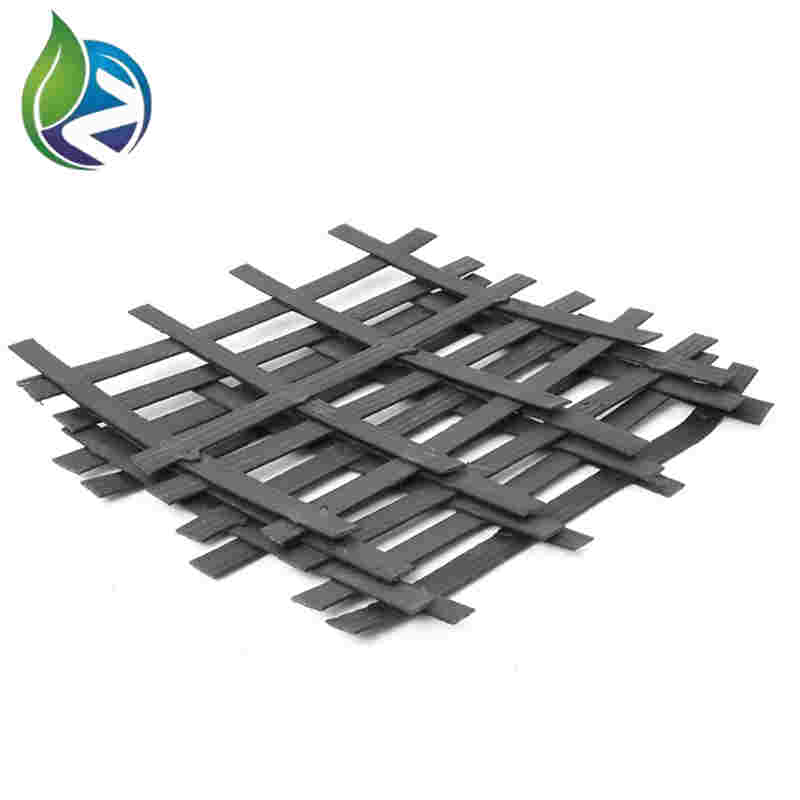

PET Welded Geogrid is a biaxial or uniaxial polymer reinforcement material manufactured from high-tenacity polyester (PET) strips that are precision welded at junctions to form a stable grid structure, used in soil stabilization, load distribution, and long-term pavement reinforcement engineering.

Technical Parameters and Specifications

PET Welded Geogrid is engineered to meet geotechnical and civil infrastructure requirements under long-term static and dynamic loading.

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Tensile Strength (MD/CD) | 20–200 kN/m | ASTM D6637 / ISO 10319 |

| Junction Efficiency | ≥ 90% | ASTM D6637 |

| Creep Reduction Factor | 1.2–1.6 | ISO 13431 |

| Elongation at Break | 8–12% | ISO 10319 |

| Aperture Size | 25 × 25 mm to 100 × 100 mm | Manufacturer Standard |

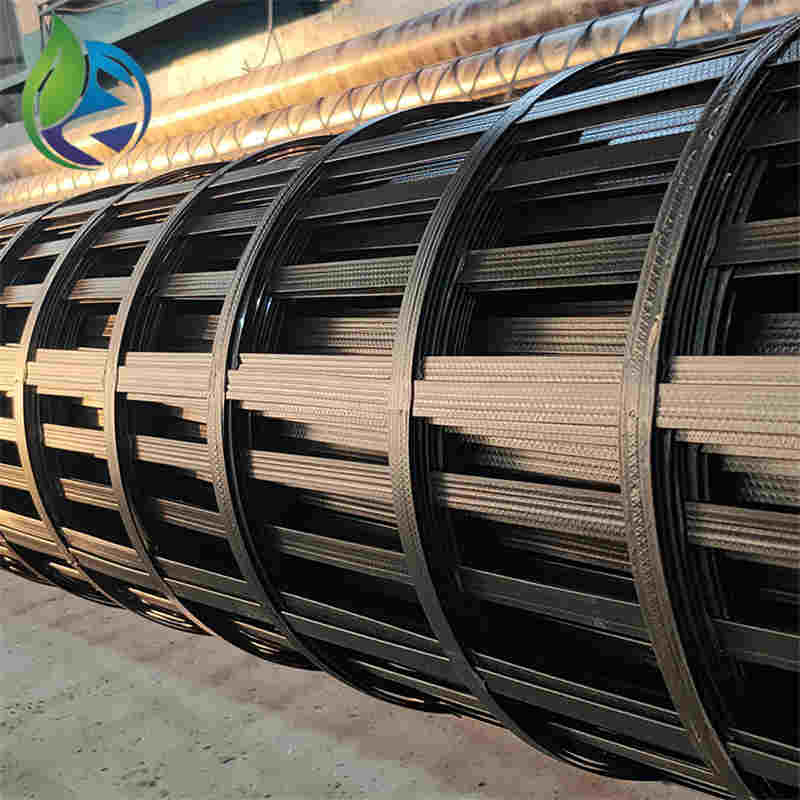

| Roll Width | 2.0–5.2 m | Project Requirement |

Structure and Material Composition

The engineered structure of PET Welded Geogrid ensures consistent load transfer and mechanical interlock with granular materials.

Core Material: High-tenacity polyester (PET) strips

Junction Method: Thermal or ultrasonic welding

Surface Treatment: Bitumen or PVC coating (optional)

Grid Geometry: Square or rectangular load-distribution apertures

Edge Reinforcement: Selvaged boundaries to prevent edge tearing

Manufacturing Process

The production of PET Welded Geogrid follows controlled industrial procedures to ensure stable mechanical properties and long-term durability.

PET resin drying and melt extrusion into flat strips.

Precision stretching through multi-zone orientation lines.

Grid layout positioning using automated alignment frames.

Thermal or ultrasonic welding at junction nodes.

Surface coating via inline calender or dipping units.

Dimensional inspection and tensile testing before roll forming.

Industry Comparison

| Material Type | Reinforcement Capacity | Creep Resistance | Cost Efficiency | Typical Applications |

|---|---|---|---|---|

| PET Welded Geogrid | High | Excellent | High | Road base, embankments, retaining walls |

| PP Extruded Geogrid | Medium | Moderate | Medium | Light traffic roads |

| Steel Mesh | Very High | Excellent | Low | Heavy-duty structural reinforcement |

| Woven Geotextile | Low | Low | High | Separation and filtration layers |

Application Scenarios

PET Welded Geogrid is widely specified by EPC contractors, distributors, and infrastructure developers in large-scale civil projects.

Highway and expressway base course stabilization

Railway subgrade reinforcement systems

Retaining wall backfill reinforcement

Port and airport pavement structures

Industrial platform and container yard foundations

Core Problems and Engineering Solutions

Problem: Subgrade settlement under cyclic loading

Solution: PET Welded Geogrid increases lateral confinement and load distribution.Problem: Weak soil bearing capacity

Solution: Grid-soil interlock improves composite modulus.Problem: Rutting in asphalt pavement

Solution: Reinforcement layer reduces shear deformation.Problem: Differential settlement at transitions

Solution: Multi-layer grid installation stabilizes stress gradients.

Risk Warnings and Mitigation Recommendations

Avoid prolonged UV exposure without protective cover during storage.

Do not install over sharp stones without a leveling sand layer.

Control welding quality to prevent node failure in customized grids.

Verify chemical compatibility in contaminated soil environments.

Procurement and Selection Guide

Confirm project load class and design life requirements.

Calculate required tensile strength per national codes.

Select aperture size based on aggregate gradation.

Verify junction efficiency test reports.

Check coating specifications for chemical resistance.

Assess supplier production capacity and quality systems.

Request project-specific samples for laboratory verification.

Engineering Case Study

In a coastal industrial logistics park project, PET Welded Geogrid with tensile strength of 120 kN/m was installed in two layers within a 600 mm crushed stone base. The system reduced measured post-construction settlement by 38% compared to traditional unreinforced sections, and improved plate load test results from 120 MPa to 185 MPa after reinforcement.

FAQ

Q1: What is the typical service life of PET Welded Geogrid?

A: 50–120 years under standard buried conditions.Q2: Can PET Welded Geogrid be used in chemically aggressive soils?

A: Yes, with appropriate protective coating.Q3: What is the standard roll length?

A: 50–100 m depending on model.Q4: Is field welding required?

A: No, grid is factory welded.Q5: Can it be installed in wet conditions?

A: Yes, with proper drainage preparation.Q6: Is PET Welded Geogrid recyclable?

A: Industrial recycling is possible.Q7: Does it require special anchorage?

A: Typically fixed with U-shaped pins or backfill confinement.Q8: What is the minimum overlap requirement?

A: 300–500 mm based on design.Q9: How is quality verified on site?

A: Through tensile and junction integrity tests.Q10: Is custom size production available?

A: Yes, subject to batch and tooling feasibility.

CTA

For project quotation, technical datasheets, and engineering samples of PET Welded Geogrid, procurement departments and EPC contractors are invited to submit detailed inquiry specifications for professional technical response.

E-E-A-T Author Credentials

This technical article is prepared by a geosynthetic materials engineer with over 15 years of experience in highway, railway, and large-scale infrastructure reinforcement projects, contributing to national and international standards development and peer-reviewed geotechnical publications.

Packaging:

Customer's company Logo mark can be added.

Packed in woven bags.