Waterproof Hdpe Geomembrane

Manufacturing Process

The manufacturing of Waterproof HDPE Geomembrane follows a controlled industrial process:

Resin Compounding: HDPE resin blended with stabilizers and additives

Extrusion: Flat-die or blown film extrusion forms continuous sheets

Surface Texturing: Optional embossing for increased friction

Cooling and Calibration: Ensures uniform thickness and flatness

Online Inspection: Thickness, surface, and defect monitoring

Mechanical Testing: Tensile, tear, and puncture performance verification

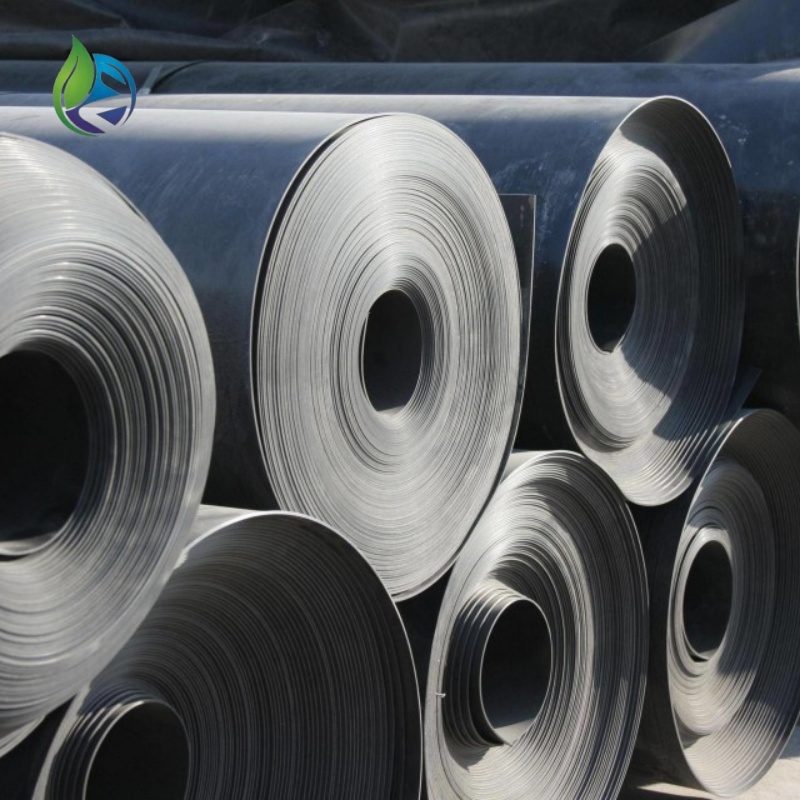

Rolling and Packaging: Controlled winding to prevent deformation

Product Definition

Waterproof HDPE Geomembrane is a high-performance impermeable liner manufactured from high-density polyethylene resin, designed to provide long-term waterproofing and containment for environmental, civil, and hydraulic engineering projects requiring reliable fluid and gas barriers.

Technical Parameters and Specifications

The following parameters are commonly referenced in engineering design, tender documents, and procurement specifications for Waterproof HDPE Geomembrane:

Raw Material: High-density polyethylene (HDPE)

Thickness Range: 0.5 mm – 3.0 mm

Standard Width: 5.0 m – 8.0 m

Roll Length: 50 m – 200 m

Tensile Strength at Yield: ≥ 15 MPa

Elongation at Break: ≥ 700%

Puncture Resistance: ≥ 300 N

Carbon Black Content: 2.0% – 3.0%

UV Resistance: ≥ 90% retained after 1600 hours

Service Life: ≥ 50 years under standard conditions

Structure and Material Composition

Waterproof HDPE Geomembrane is a homogeneous polymer sheet engineered for durability and chemical stability:

HDPE Polymer Matrix: Provides impermeability and chemical resistance

Carbon Black Additives: Enhance UV stability and weather resistance

Antioxidants: Slow thermal aging and oxidation

Smooth or Textured Surface: Optional for slope friction and anchorage

Manufacturing Process

The manufacturing of Waterproof HDPE Geomembrane follows a controlled industrial process:

Resin Compounding: HDPE resin blended with stabilizers and additives

Extrusion: Flat-die or blown film extrusion forms continuous sheets

Surface Texturing: Optional embossing for increased friction

Cooling and Calibration: Ensures uniform thickness and flatness

Online Inspection: Thickness, surface, and defect monitoring

Mechanical Testing: Tensile, tear, and puncture performance verification

Rolling and Packaging: Controlled winding to prevent deformation

Industry Comparison

| Material Type | Impermeability | Chemical Resistance | Flexibility | Lifecycle Cost |

|---|---|---|---|---|

| Waterproof HDPE Geomembrane | Excellent | Excellent | High | Medium |

| PVC Liner | Good | Moderate | Very High | Medium |

| EPDM Rubber | Excellent | Good | Very High | High |

| Clay Liner | Moderate | Low | Low | High |

Application Scenarios

Waterproof HDPE Geomembrane is specified by EPC contractors, engineering consultants, and distributors for:

Landfill bottom liners and capping systems

Mining leach pads and tailings ponds

Wastewater treatment lagoons

Reservoirs, canals, and irrigation ponds

Industrial liquid containment facilities

Aquaculture ponds and water storage tanks

Core Pain Points and Engineering Solutions

Leakage Risk: High-density polymer structure ensures zero permeability

Chemical Degradation: HDPE resists acids, alkalis, and hydrocarbons

UV Exposure: Carbon black stabilization extends outdoor service life

Installation Stress: High elongation absorbs subgrade movement

Risk Warnings and Mitigation Measures

Subgrade must be properly compacted and free of sharp objects

Qualified welding technicians are required for seam integrity

Thermal expansion should be considered during installation

Protective geotextiles are recommended for puncture prevention

Procurement and Selection Guide

Define project application and containment requirements

Select thickness based on hydraulic pressure and load

Determine smooth or textured surface requirements

Verify compliance with ASTM or ISO standards

Review factory quality control and test reports

Confirm installation support and seam testing procedures

Engineering Case Study

In a municipal wastewater lagoon project, a 1.5 mm Waterproof HDPE Geomembrane was installed over a compacted clay subgrade with protective geotextile layers. Double-track hot wedge welding and vacuum testing ensured seam integrity. After five years of operation, no leakage or material degradation was observed.

Frequently Asked Questions

Q1: Is HDPE geomembrane fully waterproof?

A: Yes, it provides near-zero permeability.Q2: What thickness is commonly used?

A: 1.0–2.0 mm for most applications.Q3: Can it resist chemicals?

A: Yes, it has excellent chemical resistance.Q4: Is UV exposure an issue?

A: Carbon black ensures UV stability.Q5: How are seams welded?

A: Hot wedge or extrusion welding.Q6: Can it be used on slopes?

A: Yes, textured surfaces improve friction.Q7: What is the expected lifespan?

A: Over 50 years under normal conditions.Q8: Is protective geotextile required?

A: Recommended for puncture resistance.Q9: What standards apply?

A: ASTM D638, D6693, ISO equivalents.Q10: Can geomembrane be repaired?

A: Yes, localized patch welding is possible.

Call to Action

For project-specific quotations, technical datasheets, or waterproof HDPE geomembrane samples, submit your engineering requirements to receive professional technical and procurement support.

E-E-A-T Author Credentials

This article is prepared by professionals specializing in geosynthetics engineering, containment system design, and environmental infrastructure projects, with extensive experience supporting EPC contractors and international procurement teams.