Geocell for Slope Protection

Manufacturing Process

The production of Geocell for Slope Protection follows a standardized industrial workflow:

Resin Preparation: HDPE resin mixed with stabilizers and carbon black

Sheet Extrusion: Flat extrusion lines produce uniform HDPE sheets

Strip Cutting: Sheets cut into precise-width strips

Welding: Ultrasonic or hot welding forms cellular joints

Perforation: Optional punching for drainage and root penetration

Expansion Testing: Verifies dimensional stability

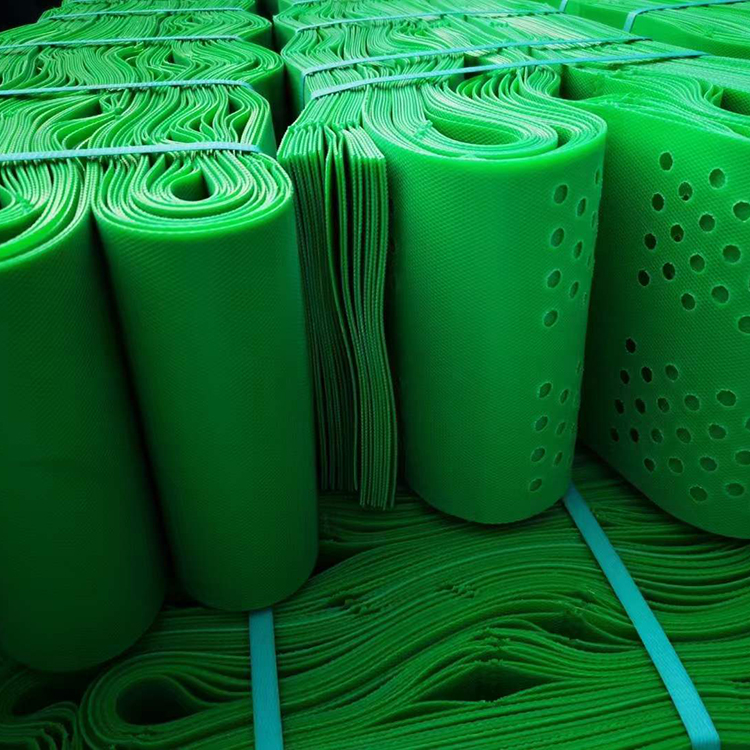

Inspection and Packing: Mechanical tests and compact folding for transport

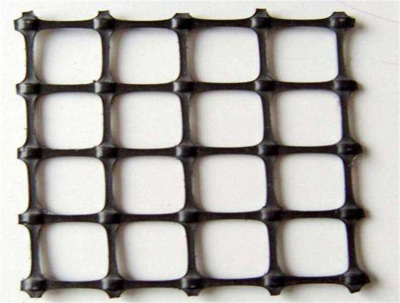

Product Definition

Geocell for Slope Protection is a three-dimensional cellular confinement system manufactured from high-density polyethylene, designed to stabilize slopes, prevent erosion, and improve load distribution by confining infill materials within interconnected cells under civil and geotechnical engineering conditions.

Technical Parameters and Specifications

The following parameters are commonly adopted in engineering design and procurement of Geocell for Slope Protection:

Raw Material: High-density polyethylene (HDPE)

Cell Height: 50 mm / 75 mm / 100 mm / 150 mm / 200 mm

Cell Size (Expanded): 210 × 210 mm or 250 × 250 mm

Sheet Thickness: 1.1 mm – 1.8 mm

Weld Peel Strength: ≥ 1000 N/100 mm

Tensile Strength: ≥ 20 MPa

Carbon Black Content: 1.5% – 2.5%

Operating Temperature: -40°C to +80°C

Design Service Life: ≥ 40 years under normal exposure

Structure and Material Composition

Geocell for Slope Protection adopts a honeycomb-like cellular structure formed by ultrasonic or thermal welding:

HDPE Strips: Provide flexibility, tensile strength, and chemical resistance

Welded Joints: Ensure structural integrity under shear and tensile stress

Perforated or Smooth Walls: Optional for drainage and vegetation integration

Three-Dimensional Cells: Confine soil, gravel, or concrete infill

Manufacturing Process

The production of Geocell for Slope Protection follows a standardized industrial workflow:

Resin Preparation: HDPE resin mixed with stabilizers and carbon black

Sheet Extrusion: Flat extrusion lines produce uniform HDPE sheets

Strip Cutting: Sheets cut into precise-width strips

Welding: Ultrasonic or hot welding forms cellular joints

Perforation: Optional punching for drainage and root penetration

Expansion Testing: Verifies dimensional stability

Inspection and Packing: Mechanical tests and compact folding for transport

Industry Comparison

| Solution Type | Erosion Control | Structural Reinforcement | Construction Speed | Lifecycle Cost |

|---|---|---|---|---|

| Geocell for Slope Protection | Excellent | High | Fast | Medium |

| Riprap Stone | Good | Medium | Slow | High |

| Concrete Slope Lining | Excellent | Very High | Medium | High |

| Vegetative Mat | Moderate | Low | Fast | Low |

Application Scenarios

Geocell for Slope Protection is widely specified by EPC contractors, distributors, and engineering consultants for:

Highway and railway embankment slopes

Riverbank and canal slope stabilization

Landfill side slopes and capping systems

Mining waste dumps and haul road slopes

Retaining structure backslopes

Green slope protection with vegetation infill

Core Pain Points and Engineering Solutions

Slope Erosion: Cellular confinement reduces soil displacement under rainfall

Shear Failure: Improved load distribution limits downslope movement

Vegetation Loss: Cells protect root systems and retain moisture

High Maintenance Costs: Durable HDPE structure minimizes long-term repairs

Risk Warnings and Mitigation Measures

Ensure proper anchoring to prevent sliding on steep slopes

Avoid low-quality welds that reduce tensile performance

Select UV-stabilized material for exposed environments

Use appropriate infill material to match slope gradient

Procurement and Selection Guide

Define slope angle, height, and soil conditions

Select cell height based on erosion intensity

Determine perforated or non-perforated configuration

Verify mechanical and weld strength test reports

Confirm compatibility with infill material

Assess installation guidance and technical support availability

Engineering Case Study

In a highway expansion project, Geocell for Slope Protection with 150 mm cell height was installed on a 1:1.5 embankment slope. The cells were anchored at the crest, infilled with topsoil, and hydroseeded. After three monsoon seasons, no visible erosion or slope failure occurred, confirming long-term stability.

Frequently Asked Questions

Q1: What slope angle is suitable?

A: Up to 70° with proper anchoring.Q2: Can geocells support vegetation?

A: Yes, with soil or sand infill.Q3: Are geocells UV resistant?

A: Yes, with carbon black stabilization.Q4: What infill materials are recommended?

A: Soil, gravel, or concrete.Q5: How are geocells installed?

A: Expanded, anchored, and infilled.Q6: Are geocells reusable?

A: Generally designed for permanent installation.Q7: Do perforations affect strength?

A: Slightly, but improve drainage.Q8: What standards apply?

A: ASTM, ISO, or project specifications.Q9: Can geocells be combined with geotextiles?

A: Yes, for filtration and separation.Q10: What is the typical service life?

A: Over 40 years.

Call to Action

For engineering quotations, technical datasheets, or slope protection project samples using Geocell for Slope Protection, please submit your project parameters to receive professional technical and procurement support.

E-E-A-T Author Credentials

This article is authored by geotechnical engineers with extensive experience in slope stabilization, erosion control systems, and geosynthetic applications for transportation, environmental, and infrastructure projects worldwide.