Corrosion-resistant Plastic Geonet

1.Uniform structure, it can withstand heavy loads. Improve the bearing capacity and stability of the foundation.

2.Anti-aging, corrosion resistance, prevent roadbed cracks, enhance pavement stability, prevent cracks.

3.Strong flexibility, good permeability.

4.Strong plasticity, easy to cut and construction.

In challenging environments where moisture, chemicals, or acidic soils are present, a corrosion-resistant plastic geonet is not just a smart choice—it's a necessity. Whether you're dealing with landfill drainage, mining operations, road subgrades, or retaining wall backfills, selecting the right drainage and reinforcement material makes all the difference in project longevity and structural integrity.

This guide will walk you through everything you need to know about corrosion-resistant plastic geonet, from its composition and benefits to real-world applications and user experiences—so you can make a fully informed purchase.

What Is a Corrosion-Resistant Plastic Geonet?

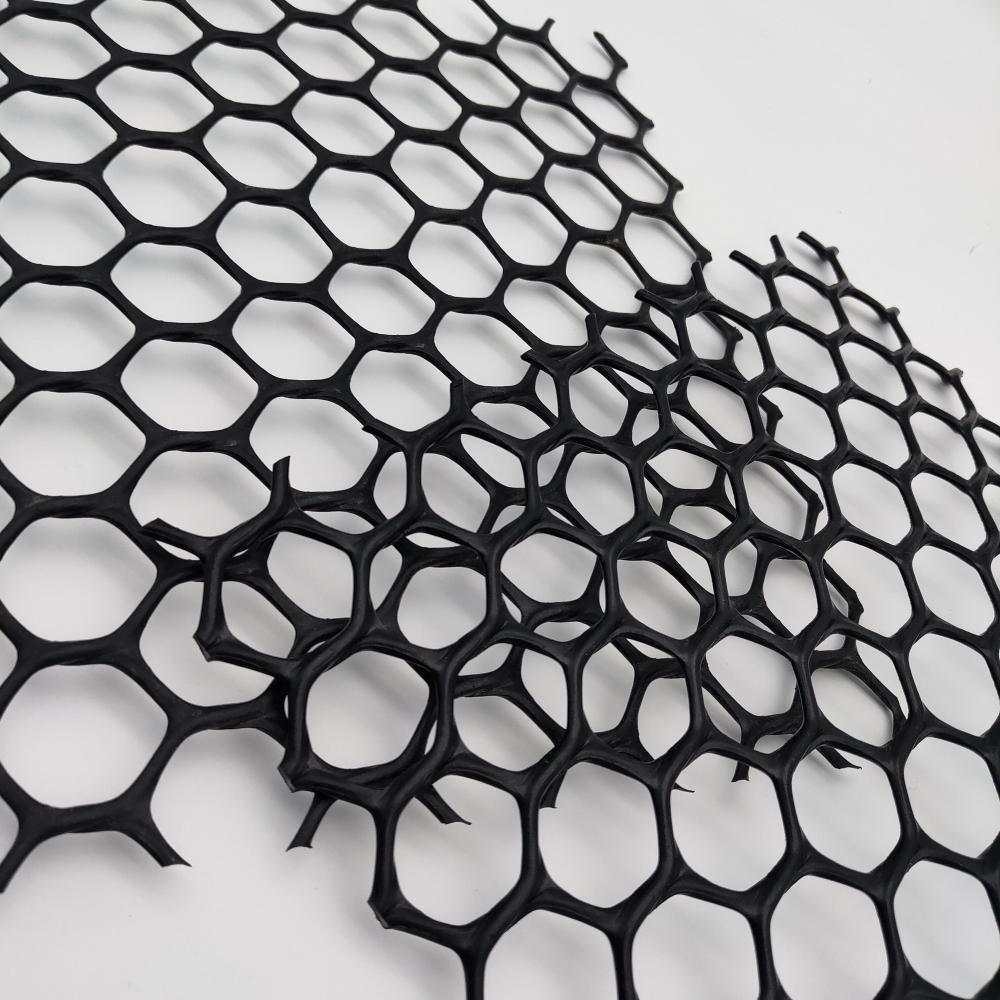

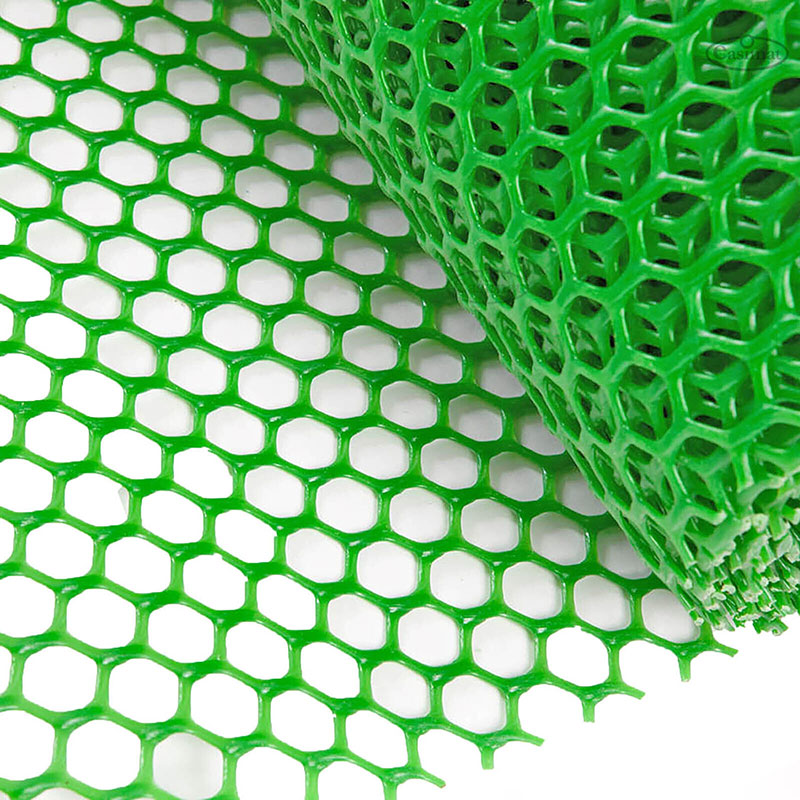

A corrosion-resistant plastic geonet is a geosynthetic material made of high-density polyethylene (HDPE) or polypropylene. It features a grid-like, netted structure designed to provide efficient drainage and reinforcement in soils. What sets this geonet apart is its exceptional resistance to chemical corrosion, making it ideal for harsh or contaminated environments.

Its layered structure—typically biplanar or triplanar—ensures consistent water flow and superior compressive strength. It’s often used in combination with geotextiles to create a composite drainage system.

✅ Fun Fact: Geonets are used in nuclear waste containment sites due to their long-term durability and corrosion resistance.

Key Features of Corrosion-Resistant Plastic Geonet

Chemical & Acid Resistance: Ideal for mining, landfill, and industrial zones.

UV Stabilized: Designed for long-term outdoor exposure.

High Flow Capacity: Maintains drainage performance under heavy loads.

Excellent Durability: Withstands aging, deformation, and compressive pressure.

Lightweight & Flexible: Easy to handle and install in difficult terrain.

Why Engineers Are Choosing Corrosion-Resistant Plastic Geonet

1. Long-Term Reliability

The corrosion-resistant plastic geonet maintains its integrity over decades, even when exposed to aggressive chemicals, acidic soils, or saline water. This makes it a favorite in infrastructure that demands zero tolerance for failure.

? "We used corrosion-resistant plastic geonets in a copper mining site in Chile. Five years in, drainage is flawless and no sign of degradation."

— Carlos M., Site Engineer

2. Versatile Drainage Applications

From landfills to tunnels, from retaining walls to athletic field subbases, corrosion-resistant plastic geonet offers a reliable drainage layer that prevents waterlogging and protects structural fill.

3. Cost-Efficient Alternative

Although the upfront investment in corrosion-resistant plastic geonet may seem higher than traditional gravel-based systems, its ease of installation, lightweight design, and long lifespan make it far more economical over time.

? “We cut labor costs by nearly 30% when switching to plastic geonets for our sports field drainage system. It’s efficient and maintenance-free.”

— Katrina J., Landscape Architect

Common Uses of Corrosion-Resistant Plastic Geonet

Landfill Drainage Layers

Underground Mining Waste Filtration

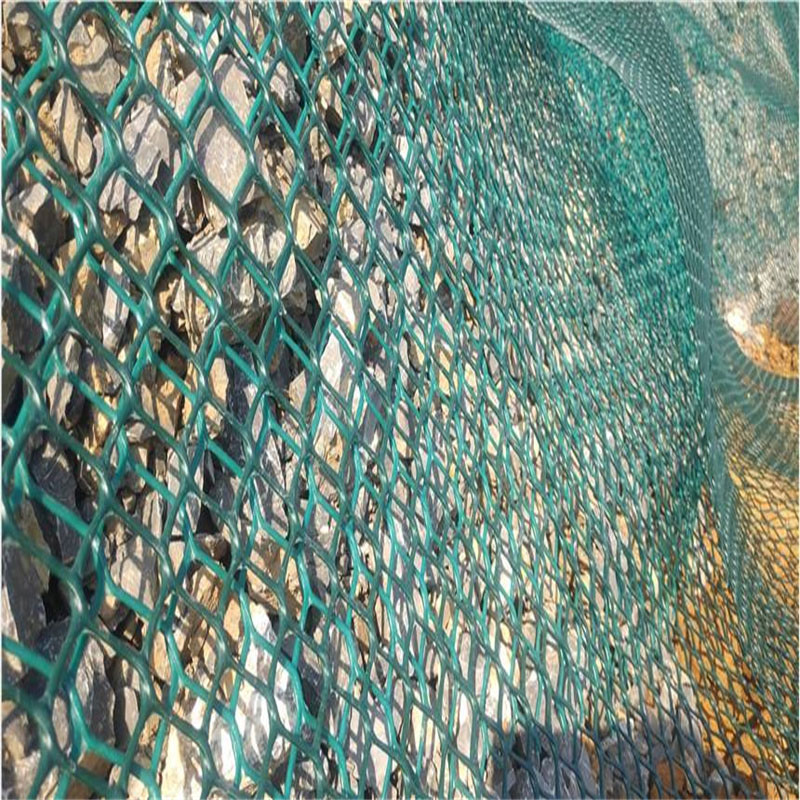

Retaining Wall Backfill Drainage

Railway & Road Subgrade Stabilization

Tunnel Drainage Systems

Agricultural Reservoirs & Canals

Installation Insights & Best Practices

Surface Preparation: Level and compact the area before installation.

Geotextile Integration: For maximum filtration, pair the geonet with a nonwoven geotextile layer.

Edge Overlap: Overlap adjacent geonet rolls by 10–15 cm to maintain hydraulic continuity.

Avoid Direct UV Prolonged Exposure: Though UV stabilized, cover the geonet promptly with soil or protection layers during installation.

? Pro Tip: Triplanar geonets are often preferred for high-load drainage projects due to their superior compression strength.

Simulated Customer Reviews

⭐⭐⭐⭐⭐

“I’ve used corrosion-resistant plastic geonet across three landfill projects now. The chemical resistance is unmatched, and the installation couldn’t be simpler.”

— James D., Environmental Consultant, Texas

⭐⭐⭐⭐

“We needed something robust for our seawall drainage system. This geonet has held up perfectly against saltwater intrusion and remains fully functional.”

— Elena V., Coastal Engineer, Portugal

⭐⭐⭐⭐⭐

“Excellent performance and fast delivery. Worked well for the tunnel drainage—we’ll be ordering again for our next phase.”

— Leo R., Project Manager, Infrastructure Co.

Is Corrosion-Resistant Plastic Geonet Right for Your Project?

If your construction or environmental engineering project demands a long-lasting, high-performance drainage and reinforcement solution in corrosive or moisture-heavy environments, the answer is a resounding yes.

The corrosion-resistant plastic geonet is not just a product—it’s peace of mind. It keeps water moving, resists environmental stress, and ensures your foundation stays secure.